I-Rection edityanisiweyo ye-silicon carbide case-crucible

Imveliso ilungele i-industrial kiln, i-sintering, ukunyibilika kunye nokusebenza kuzo zonke iintlobo zeemveliso. Kwintsimi yoshishino lweekhemikhali, i-petroleum kunye nokukhuselwa kwendalo kunye noluhlu olubanzi lwezicelo.

1) Ukuzinza kokutshatyalaliswa kobushushu

2) ikhemikhali i-corrosion-resistant

3) Umsindo ophezulu-ukunyamezela (ukuya kwi-1650 °

4) Ukunxiba / ukubola / ukumelana ne-oxidation

5) Ukusebenza okuphezulu kwamandla omatshini

6) Ukucoca okanye ukucoca eyona ndawo inzima kakhulu

7) Isetyenziselwa ukusila, ukuxhakazela, kunye nokusika i-wire saw kunye nokuqhunyiswa kwe-abrasive

| Ukwakheka kwemichiza SIC >= | % | 90 | |

| Ubukhulu benkonzo Temp. | ºC | 1400 | |

| Ukuchasa >= | SK | 39 | |

| 2kg/cm2 Refractoriness phantsi komthwalo T2 >= | ºC | 1790 | |

| Ipropati yeFiziksi | Imodyuli yeRupturt kwiqondo lobushushu begumbi >= | Kg/cm2 | 500 |

| Imodyuli yokuQhuba kwi-1400ºC >= | Kg/cm2 | 550 | |

| Amandla acinezelayo >= | Kg/cm2 | 1300 | |

| Ukwandiswa kweThermal kwi-1000ºC | % | 0.42-0.48 | |

| I-Porosity ebonakalayo | % | ≤20 | |

| Unizi lolwapho kuyiwa khona | g/cm3 | 2.55-2.7 | |

| I-Thermal Conductivity kwi-1000ºC | Kcal/m.hr.ºC | 13.5-14.5 | |

Inkcazo:

I-crucible yimbiza ye-ceramic esetyenziselwa ukubamba isinyithi sokunyibilika kwiziko. Lo ngumgangatho ophezulu, ibakala lemveliso elisetyenziswa lishishini elisisiseko sorhwebo.

Yintoni Eyenzayo:

I-crucible iyafuneka ukumelana namaqondo obushushu agqithisileyo afunyenwe kwiintsimbi ezinyibilikayo. Izinto ezicholwayo kufuneka zibe nenqanaba eliphezulu lokunyibilika kunelo lentsimbi enyibilikayo kwaye kufuneka libe namandla alungileyo naxa kushushu kumhlophe.

Kuyenzeka ukuba kusetyenziswe indlu eyenziwe ngentsimbi yentsimbi ukunyibilikisa iintsimbi ezifana ne-zinc kunye ne-aluminiyam, kuba ezi ntsimbi zinyibilika kwiqondo lobushushu elingaphantsi kwentsimbi. Nangona kunjalo ukukala (ukugqabhuka) komgangatho ongaphakathi wentsimbi yingxaki. Esi sikali sinokungcolisa inyibilika kwaye sinciphise iindonga ezinqamlekileyo kunoko ngokukhawuleza. Izibonda zentsimbi ziya kusebenza ukuba usandula ukuqalisa kwaye ungakhathali ukujongana nokukalwa.

Izinto eziqhelekileyo ezichasayo ezisetyenziselwa ukwakhiwa kwe-crucible yi-clay-graphite, kunye ne-carbon bonded silicon-carbide. Ezi zixhobo zinokumelana namaqondo obushushu aphezulu kumsebenzi wesiseko esiqhelekileyo. I-silicon carbide inenzuzo eyongezelelweyo yokuba yinto ehlala ixesha elide.

Izikrubhile zethu zeMilo yeGrafite yeGraphite zithelekelelwa kwi-2750 °F (1510 °C). Baza kuphatha i-zinc, i-aluminium, ubhedu / ubhedu, isilivere kunye negolide. Umenzi uthi zingasetyenziselwa intsimbi etyhidiweyo. Yenziwe eUnited States!

Iimilo zeCrucible:

I-bilge shaped ("B" Shape) into emile okwebhobho yewayini. Ubungakanani be "bilge" bububanzi be-crucible kwindawo ebanzi kakhulu. Ukuba akukho dayamitha ye-bilge ebonisiweyo ngoko ke i-diameter ephezulu bukhulu bobubanzi.

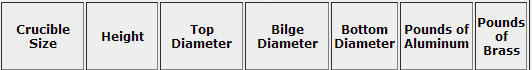

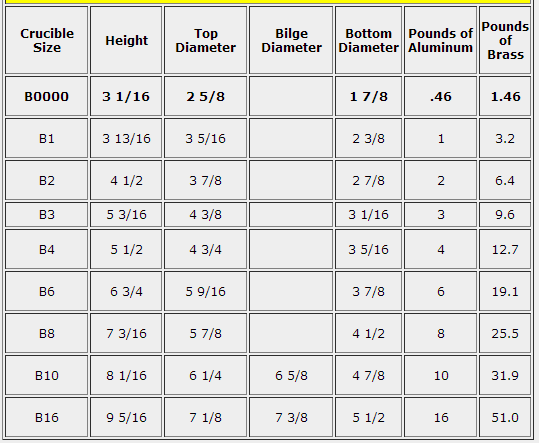

Umgaqo wesithupha uthi i-# ye-"bilge" crucible inika amandla ayo okusebenza malunga neepounds ze-aluminium. Ubhedu okanye ubhedu sebenzisa amaxesha ama-3 e-crucible #. Umzekelo #10 crucible ingabamba malunga 10 pounds aluminiyam kunye 30 pounds zobhedu.

Iicrucibles zethu zemilo "B" zidla ngokusetyenziswa ngabantu abathanda ukuzilibazisa kunye neecasters rhoqo. Ezi zikumgangatho ophezulu, ezihlala ixesha elide kwibakala lorhwebo.

Jonga ezi theyibhile zingezantsi ukufumana ubungakanani obufanelekileyo bomsebenzi wakho.

Isetyenziswa njani:

Zonke ii-crucibles kufuneka ziphathwe ngeetongs ezifanelekileyo ezifanelekileyo (isixhobo sokuphakamisa). I-tongs engafanelekanga inokubangela umonakalo okanye ukungaphumeleli ngokupheleleyo kwe-crucible ngexesha elibi kakhulu.

Idiski yekhadibhodi inokufakwa phakathi kwe-crucible kunye nesiseko somlilo ngaphambi kokufudumala. Oku kuya kutshisa, kushiye umaleko wekhabhoni phakathi kwaye kuthintele i-crucible ukuba ibambelele phantsi kwesithando somlilo. Ingubo yePlumbago (iCarbon Black) yenza into efanayo.

Kungcono ukusebenzisa i-crucible eyahlukileyo yohlobo ngalunye lwetsimbi ukuze ugweme ukungcoliswa. Kwakhona qiniseka ukuba ukhuphe ngokupheleleyo i-crucible emva kokusetyenziswa. I-Metal eshiywe ukuqinisa kwi-crucible inokwandisa ekufudumeni kwakhona kwaye iyitshabalalise.

Nceda ucaphukise amabhonkco amatsha okanye ezo bezigcinwe. Fudumeza i-crucible engenanto kwiiyure ze-2 kwi-220 F (104 C). (Sebenzisa umoya owaneleyo. Izikhephe ezitsha ziya kutshaya njengoko i-glaze ibeka.) Emva koko tshisa i-crucible engenanto kubushushu obubomvu. Vumela i-crucible ukuba ipholise kwiqondo lokushisa kwigumbi kwisithando somlilo ngaphambi kokusetyenziswa. Le nkqubo kufuneka ilandelwe ZONKE ii-crucibles ezitsha kunye nayo nayiphi na i-crucible enokuthi ibonakaliswe kwiimeko ezimanzi kwindawo yokugcina.

Gcina zonke ii-crucibles kwindawo eyomileyo. Ubumanzi bunokubangela ukuba i-crucible iqhekeke ekufudumeni. Ukuba igcinwe ixesha elide, kungcono ukuphinda ubushushu.

I-silicon carbide crucibles lolona hlobo luncinci lokufunxa amanzi kwindawo yogcino kwaye aludingi kucutshungulwa phambi kokusetyenziswa. Kungumbono olungileyo ukutshisa i-crucible entsha kubushushu obubomvu ngaphambi kokusetyenziswa kwayo okokuqala ukuqhubela phambili kunye nokuqinisa iingubo zefektri kunye nezibophelelo.

Izinto eziphathekayo kufuneka zifakwe kwi-crucible KAKHULU ngokukhululekileyo. UNGAZE "upakishe" i-crucible, njengoko izinto eziphathekayo ziya kwandiswa ekufudumeni kwaye zikwazi ukuqhekeza i-ceramic. Emva kokuba le nto inyibilikile "kwisithende", layisha ngokucophelela izinto ezininzi kwi-puddle yokunyibilika. (ISILUMKISO: Ukuba KUKHO NAKUPHI ukufuma kwisixhobo esitsha kuya kubakho UKUPHUPHUMA komphunga). Kwakhona, musa ukupakisha ngokuqinileyo kwintsimbi. Gcina ukondla izinto eziphathekayo kwi-melted de ubuninzi obufunekayo buncibilike.

ISILUMKISO!!!: Izibonda ziyingozi. Ukunyibilika kwesinyithi kwi-crucible kuyingozi. Ukugalela isinyithi kwiimbumba kuyingozi. I-crucible inokusilela ngaphandle kwesilumkiso. I-Crucibles inokuquka iziphene ezifihliweyo kwizinto eziphathekayo kunye nokuveliswa okungakhokelela ekungaphumeleli, umonakalo wepropathi, ukulimala komntu, ukulimala kwababukele kunye nokulahlekelwa ubomi.

Ibhloko yeSiseko seCrucible

Inkcazo:

I-BCS Ibhloko yesiseko yisiseko sobushushu obuphezulu esisetyenziselwa ukuphakamisa i-crucible ukuya kwindawo yobushushu beziko.

Yintoni Eyenzayo:

Ibhloko yesiseko idla ngokusetyenziswa kwiziko elitshiswe ngerhasi ukuphakamisa isikhonkwane phezulu ukuze idangatye lomlilo lingagqabhuki ngokuthe ngqo kudonga olucekethekileyo lwento enye. Ukuba idangatye lesitshisi livunyelwe ukuba libethe ngqo kwi-crucible linokubangela ukukhukuliseka kodonga lwe-crucible ngaloo ndlela lifutshane ubomi bayo. Indlela efanelekileyo yokuthintela oku kukusebenzisa ibhloko yesiseko ukuphakamisa i-crucible ngaphandle kwendawo yokutshisa.

Ukuphakamisa i-crucible kwakhona kuvumela ukuba ibe "kwindawo yokushisa" yesithando somlilo. Nangona idangatye lomlilo lingena kumzimba wesithando somlilo ezantsi eyona ndawo ishushu kakhulu isuka phakathi ukuya phezulu. Kukulo mmandla apho iindonga zesithando somlilo zifudumeza igesi ejikelezayo ngokufanelekileyo. Ukuba namacala e-crucible kulo mmandla kukhuthaza ukufudumeza okulungileyo ukusuka kwi-turbulent gas stream kunye nokufudumala kwemitha yeendonga zangaphakathi ezivuthayo.

Isetyenziswa njani:

Ibhloko yesiseko kufuneka ibe mde ngokwaneleyo ukuba i-flame yokutshisa ihambelane nomphezulu webhloko. Kulungile ukuba umphezulu webhloko uphezulu kune-inlet yokutshisa. Into ongayifuniyo kukuba ilangatye libethe amacala amancinci e-crucible. Kwamkelekile kwakhona ukuba ilangatye libetha isahlulo esisezantsi se-crucible njengoko le nxalenye ingenakusebenziseka ukunxiba kwigesi.

I-Shandong Zhongpeng Special Ceramics Co., Ltd yenye yezona zisombululo zikhulu ze-silicon carbide zeceramic ze-ceramic e-China. I-ceramic yobugcisa be-SiC: Ubulukhuni be-Moh yi-9 (ubulukhuni be-Moh entsha yi-13), kunye nokuchasana okugqwesileyo kukhukuliseko kunye nokugqwala, i-abrasion egqwesileyo - ukuxhathisa kunye ne-anti-oxidation. Ubomi benkonzo yemveliso ye-SiC yi-4 ukuya kwamaxesha ama-5 ubude ngaphezu kwe-92% yezinto ze-alumina. I-MOR ye-RBSiC yi-5 kumaxesha e-7 ye-SNBSC, ingasetyenziselwa imilo enzima ngakumbi. Inkqubo yekoteyishini ikhawuleza, ukuhanjiswa kuthenjisiwe kwaye umgangatho ungowesibini. Sihlala sizingisa ukucela umngeni kwiinjongo zethu kwaye sibuyisele iintliziyo zethu kuluntu.