Kwiminyaka yakutshanje, i-silicon carbide compound semiconductors ifumene ingqwalasela ebanzi kwishishini. Nangona kunjalo, njengento ephezulu yokusebenza, i-silicon carbide inxalenye encinci yezixhobo zombane (i-diodes, izixhobo zamandla). Isenokusetyenziswa njengama-abrasives, izinto zokusika, izinto zokwakha, izinto ezibonakalayo, abathwali be-catalyst, kunye nokunye. Namhlanje, sazisa ikakhulu ii-silicon carbide ceramics, ezinezibonelelo zokuzinza kweekhemikhali, ukumelana nobushushu obuphezulu, ukuxhathisa ukunxiba, ukumelana nokugqwala, ukuhanjiswa kwe-thermal ephezulu, i-coefficient yokwandiswa kwe-thermal ephantsi, ukuxinana okuphantsi, kunye namandla aphezulu omatshini. Zisetyenziswa ngokubanzi kwiinkalo ezifana noomatshini beekhemikhali, amandla kunye nokukhuselwa kwendalo, i-semiconductors, i-metallurgy, ukhuselo lwelizwe kunye noshishino lomkhosi.

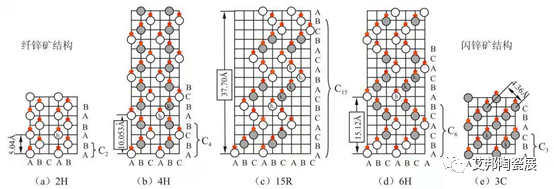

I-silicon carbide (SiC)iqulethe i-silicon kunye ne-carbon, kwaye i-multi-type structural compound, ngokukodwa iquka iifom ezimbini ze-crystal: α - SiC (uhlobo oluzinzileyo lobushushu obuphezulu) kunye ne-β - SiC (uhlobo oluzinzileyo lobushushu obuphantsi). Kukho ngaphezu kwe-200 iindidi ezininzi zizonke, phakathi kwazo i-3C SiC ye-β - SiC kunye ne-2H SiC, i-4H SiC, i-6H SiC, kunye ne-15R SiC ye-α - SiC imele.

Umfanekiso weSiC Multibody Structure

Xa iqondo lobushushu lingaphantsi kwe 1600 ℃, iSiC ikhona ngokohlobo lwe β – SiC kwaye ingalungiswa ukusuka kumxube olula wesilicon kunye nekhabhoni malunga ne-1450 ℃. Xa ubushushu bungaphezu kwe-1600 ℃, β – SiC iguquka kancinane ibe ziipolymorphs ezahlukeneyo ze-α – SiC. I-4H SiC iveliswa lula malunga ne-2000 ℃; Zombini i-6H kunye ne-15R iipolymorphs zifuna ukushisa okuphezulu ngaphezu kwe-2100 ℃ ukuze kube lula ukubunjwa; I-6H SiC inokuhlala izinzile nakwiqondo lobushushu elingaphezulu kwe-2200 ℃, iyenza isetyenziswe ngokubanzi kwizicelo zemizi-mveliso.

I-silicon carbide ecocekileyo yikristale engenambala kwaye ecacileyo, ngelixa i-silicon carbide yeshishini inokuba nemibala, tyheli, ukukhanya okuluhlaza, okuluhlaza okumnyama, okuluhlaza okwesibhakabhaka, okuluhlaza okwesibhakabhaka, okanye nokuba mnyama, kunye nokuncipha kwamanqanaba okucaca. Umzi-mveliso we-abrasive uhlela i-silicon carbide ibe zintlobo ezimbini ngokusekelwe kumbala: i-silicon carbide emnyama kunye ne-silicon carbide eluhlaza. I-silicon carbide engenambala ukuya kumnyama omnyama ihlelwa njenge-silicon carbide eluhlaza, ngelixa ukukhanya okuluhlaza ukuya kumnyama wesilicon carbide ihlelwa njenge-silicon carbide emnyama. I-silicon carbide emnyama kunye ne-silicon carbide eziluhlaza zombini ziikristale ze-alpha SiC ezinehexagonal, kunye ne-silicon carbide umgubo omncinci usetyenziswa ngokubanzi njengemathiriyeli ekrwada ye-silicon carbide ceramics.

Ukusebenza kweeCeramics zeSilicon Carbide ezilungiselelwe ziiNkqubo ezahlukeneyo

Nangona kunjalo, iiseramics ze-silicon carbide zinento engalunganga yokuqina okuphantsi kunye nokuqina okuphezulu. Ke ngoko, kwiminyaka yakutshanje, iiseramics ezihlanganisiweyo ezisekwe kwi-silicon carbide ceramics, njengefiber (okanye iwhisker) ukuqinisa, ukomelezwa kokusasazwa kwamasuntswana, kunye nezinto ezisebenzayo zegradient, ziye zavela ngokulandelelanayo, ziphucula ukuqina kunye namandla ezinto ezizimeleyo.

Njengesixhobo somgangatho ophezulu wokusebenza kwe-ceramic yobushushu obuphezulu, iiseramics ze-silicon carbide ziye zasetyenziswa kakhulu kwiikhilni ezinobushushu obuphezulu, isinyithi sesinyithi, i-petrochemicals, i-elektroniki yomatshini, i-aerospace, amandla kunye nokukhuselwa kokusingqongileyo, amandla enyukliya, iimoto kunye nezinye iindawo.

Ngo-2022, ubungakanani bemarike ye-silicon carbide structural ceramics e-China kulindeleke ukuba bufikelele kwi-18.2 yeebhiliyoni zeeyuan. Ngokwandiswa ngakumbi kweendawo zokusetyenziswa kunye neemfuno zokukhula ezisezantsi, kuqikelelwa ukuba ubungakanani bemarike ye-silicon carbide structural ceramics buza kufikelela kwi-29.6 yeebhiliyoni zeeyuan ngo-2025.

Kwixesha elizayo, ngokunyuka kwesantya sokungena kwezithuthi zamandla amatsha, amandla, ishishini, unxibelelwano kunye nezinye iindawo, kunye neemfuno ezingqongqo zokuchaneka okuphezulu, ukuchaneka okuphezulu, kunye nokuthembeka okuphezulu komatshini okanye amacandelo e-elektroniki kwiinkalo ezahlukeneyo, ubungakanani bemarike yeemveliso ze-silicon carbide ceramic kulindeleke ukuba ziqhubeke zanda, phakathi kwazo izithuthi zamandla amatsha kunye ne-photovoltaics ziyindawo ebalulekileyo yophuhliso.

I-Silicon carbide ceramics isetyenziswa kwiikhilthi ze-ceramic ngenxa yeempawu zabo ezibalaseleyo zobushushu obuphezulu, ukumelana nomlilo, kunye nokuxhathisa ukothuka kwe-thermal. Phakathi kwazo, ii-roller kilns zisetyenziselwa ukomisa, ukutshiza, kunye nokunyangwa kobushushu be-lithium-ion ibhetri ye-electrode yezinto ezilungileyo, izinto ezingalunganga ze-electrode, kunye ne-electrolytes. Ibhetri ye-lithium enezixhobo ze-electrode ezintle kunye ne-negative ziyimfuneko kwizithuthi zamandla amatsha. Ifenitshala ye-Silicon carbide ceramic kiln yinxalenye ephambili yeekhilns, ezinokuphucula umthamo wokuvelisa i-kiln kunye nokunciphisa kakhulu ukusetyenziswa kwamandla.

Iimveliso ze-silicon carbide ceramic nazo zisetyenziswa ngokubanzi kumacandelo ahlukeneyo eemoto. Ukongezelela, izixhobo ze-SiC zisetyenziswa kakhulu kwi-PCUs (iiyunithi zokulawula amandla, njengebhodi ye-DC / DC) kunye ne-OBCs (iiyunithi zokutshaja) zezithuthi zamandla amatsha. Izixhobo ze-SiC zinokunciphisa ubunzima kunye nomthamo wezixhobo ze-PCU, ukunciphisa ilahleko yokutshintsha, kunye nokuphucula ubushushu bokusebenza kunye nokusebenza kwenkqubo yezixhobo; Kwakhona kunokwenzeka ukwandisa inqanaba lamandla eyunithi, ukwenza lula ubume besiphaluka, ukuphucula ubuninzi bamandla, kunye nokunyusa isantya sokutshaja ngexesha lokutshaja kwe-OBC. Okwangoku, iinkampani ezininzi zeemoto kwihlabathi liphela zisebenzisa i-silicon carbide kwiimodeli ezininzi, kwaye ukwamkelwa okukhulu kwe-silicon carbide kuye kwaba yinto eqhelekileyo.

Xa i-silicon carbide ceramics isetyenziswa njengezinto eziphambili zokuthwala kwinkqubo yokuvelisa iiseli ze-photovoltaic, iimveliso ezibangelwayo ezifana nezixhaso zesikhephe, iibhokisi zeenqanawa, kunye nokufakwa kombhobho kunozinzo oluhle lwe-thermal, musa ukukhubaza xa kusetyenziswa kumaqondo aphezulu, kwaye musa ukuvelisa ukungcola okuyingozi. Banokutshintsha izixhaso zesikhephe zequartz ezisetyenziswa ngokuqhelekileyo, iibhokisi zesikhephe, kunye nokufakwa kwemibhobho, kwaye zineenzuzo ezinkulu zeendleko.

Ukongeza, amathemba entengiso yezixhobo zamandla e-photovoltaic silicon carbide zibanzi. Izinto ze-SiC zineentsilelo ezisezantsi zokuchasa, intlawulo yesango, kunye neempawu zentlawulo yokubuyisela umva. Ukusebenzisa i-SiC Mosfet okanye i-SiC Mosfet idibene ne-SiC SBD photovoltaic inverters inokunyusa ukuguqulwa kokuguqulwa ukusuka kwi-96% ukuya kwi-99%, ukunciphisa ukulahlekelwa kwamandla ngaphezu kwe-50%, kunye nokwandisa ubomi bomjikelezo wezixhobo ngamaxesha angama-50.

Ukwenziwa kweeseramics zesilicon carbide kunokulandwa umva ngeminyaka yoo-1890, xa i-silicon carbide yayisetyenziselwa izinto zokusila ngoomatshini kunye nezixhobo ezichasayo. Ngophuhliso lobuchwephesha bemveliso, iimveliso ze-SiC ezikumgangatho ophezulu ziye zaphuhliswa ngokubanzi, kwaye amazwe ehlabathi anikela ingqalelo ngakumbi kushishino lweeseramikhi eziphambili. Abasanelisekanga ngokulungiswa kweeseramics ze-silicon carbide zemveli. Amashishini avelisa iiseramikhi ezikumgangatho ophezulu aphuhla ngokukhawuleza ngakumbi, ngakumbi kumazwe aphuhlileyo apho le nto ibaluleke kakhulu. Abavelisi bamazwe angaphandle ikakhulu babandakanya iSaint Gobain, i-3M, iCeramTec, i-IBIDEN, iSchunk, iNarita Group, iToto Corporation, iCoorsTek, iKyocera, i-Aszac, iJapan Jingke Ceramics Co., Ltd., iJapan Special Ceramics Co., Ltd., IPS Ceramics, njl.

Ukuphuhliswa kwe-silicon carbide e-China kwakusemva kwexesha xa kuthelekiswa namazwe aphuhlileyo afana neYurophu neMelika. Ukusukela oko iziko lokuqala lokuvelisa iSiC lakhiwa kwiFactory yokuQala yokuSila iWheel ngoJuni 1951, iChina yaqalisa ukuvelisa isilicon carbide. Abavelisi basekhaya be-silicon carbide ceramics bagxile kakhulu kwiSixeko sase-Weifang, kwiPhondo laseShandong. Ngokutsho kweengcali, oku kungenxa yokuba amashishini emigodi yamalahle asekuhlaleni ajongene nokutshona kwaye afuna inguqu. Ezinye iinkampani ziye zazisa izixhobo ezifanelekileyo ezivela eJamani ukuqala ukuphanda kunye nokuvelisa i-silicon carbide.I-ZPC ngomnye wabavelisi abakhulu be-reaction sintered silicon carbide.

Ixesha lokuposa: Nov-09-2024