1. Isetyenziswa kwizinto zelitye elinqabileyo

Kwishishini lamatye anqabileyo, i-silicon carbide ikwabizwa ngokuba yi "moissanite". Izinto eziqhele ukubonwa emarikeni zenziwe nge-moissanite, ngelixa i-moissanite yendalo inqabile kakhulu, inqabile kangangokuba yavela kuphela kwi-meteorite craters kwiminyaka engama-50000 eyadlulayo.

(1) Iimveliso zokuxhathisa ubushushu obuphezulu:

Ukusebenzisa iimpawu zokunganyangeki kwe-corrosion, ukumelana nobushushu obuphezulu, amandla aphezulu, ukuguquguquka okuhle kwe-thermal, kunye nefuthe lokumelana ne-silicon carbide materials, zingasetyenziselwa iindidi ezahlukeneyo zokunyibilikisa iziko lomlilo, i-high-high-temperature plates, iipleyiti ze-silicon carbide, iipleyiti ze-lining, izixhaso, kunye neeleyile. Ngakolunye uhlangothi, izixhobo zokufudumeza ezingathanga ngqo ezinobushushu obuphezulu zinokusetyenziswa kwishishini lokunyibilikisa isinyithi esingenawo-ferrous, njengeziko le-distillation elithe nkqo, iipleyiti ze-arc ze-zinc powder furnaces, iityhubhu zokukhusela i-thermocouple, njl. Isetyenziselwa ukuvelisa izixhobo ze-silicon carbide zeceramic ezikwinqanaba eliphezulu, ezikwaziyo ukunxiba, ukumelana nokugqwala, kunye nobushushu obuphezulu; Ingasetyenziselwa ukwenza imibhobho ye-rocket, i-gas turbine blades, njl. Ukongeza, i-silicon carbide nayo enye yezinto ezifanelekileyo zokufudumala kwamanzi elanga kwiindlela ezihamba phambili, i-aircraft runways, njl. Ngoko ke, i-silicon carbide nayo inegama eliqhelekileyo elithi "isanti ye-refractory", leyo, nangona ixhaphake kakhulu, ibonisa ngokupheleleyo iimpawu zayo eziphikisayo.

(2) Nxiba imveliso exhathisayo kunye ne-corrosion:

Ikakhulu ngenxa yokuba i-silicon carbide inobunzima obuphezulu, kunye nobunzima be-Mohs be-9.2-9.8, okwesibini kuphela kwidayimane enzima kunazo zonke emhlabeni (inqanaba le-10), yaziwa ngokuqhelekileyo ngokuthi "isanti yensimbi yegolide". Kananjalo inozinzo oluhle lwekhemikhali kunye nokuqina okuthile, kwaye ingasetyenziselwa ukwenza amavili okusila, amaphepha esanti, amabhanti entlabathi, i-oilstones, iibhloko zokusila, iintloko zokusila, iipasti zokusila, kunye nokusila kunye nokupolisha isilicon ye-polycrystalline, kunye neekristale zepiezoelectric kwishishini le-elektroniki kwiimveliso zamehlo.

(3) Imathiriyeli ekrwada yeMetallurgical:

I-silicon carbide ingasetyenziselwa i-deoxidizer yokwenza i-steelmaking kunye ne-modifier yesakhiwo sentsimbi. Isenokusetyenziswa njengemathiriyeli ekrwada yokwenza i-silicon tetrachloride kwaye yeyona nto iphambili kwimveliso ye-silicone resin. I-Silicon carbide deoxidizer luhlobo olutsha lwe-deoxidizer edibeneyo edibeneyo ethatha indawo ye-silicon powder yendabuko kunye ne-carbon powder ye-deoxidation. Xa kuthelekiswa nenkqubo yokuqala, ineempawu ezizinzileyo zomzimba kunye neekhemikhali, isiphumo esihle se-deoxidation, ixesha elincinci lokuchithwa kwe-deoxidation, amandla agciniweyo, ukuphucula ukusebenza kwentsimbi, ukuphucula umgangatho wentsimbi, ukunciphisa ukusetyenziswa kwezinto eziluhlaza, ukunciphisa ukungcola kokusingqongileyo, ukuphuculwa kweemeko zokusebenza, kunye nokuphucula izibonelelo zezoqoqosho ezibanzi zeziko lombane, zonke zinexabiso elibalulekileyo.

3, Izinto zokubonisa i-silicon carbide optical reflector

Imathiriyeli yeCeramic eyenziwe kusetyenziswa imisebenzi ekhethekileyo yeeseramics ngokweempawu ezibonakalayo ezifana nesandi, ukukhanya, umbane, umazibuthe, kunye nobushushu zibizwa ngokuba ziikeramics ezisebenzayo. Kukho iintlobo ezahlukeneyo zeekeramics ezisebenzayo kunye nokusetyenziswa okwahlukileyo, kwaye i-silicon carbide isetyenziswa kakhulu njengesixhobo sesibuko esibonakalisa kwintsimi yeeseramikhi ezisebenzayo. I-ceramics ye-SiC inokuqina okuphezulu okuphezulu, ukuzinza okuhle kwe-thermal kunye neekhemikhali, i-coefficient ephantsi ye-thermal deformation, kunye nokuchasana ne-space particle irradiation. Ngeenkqubo ezikhethekileyo zokuvelisa, imizimba yesipili ekhaphukhaphu inokufumaneka.

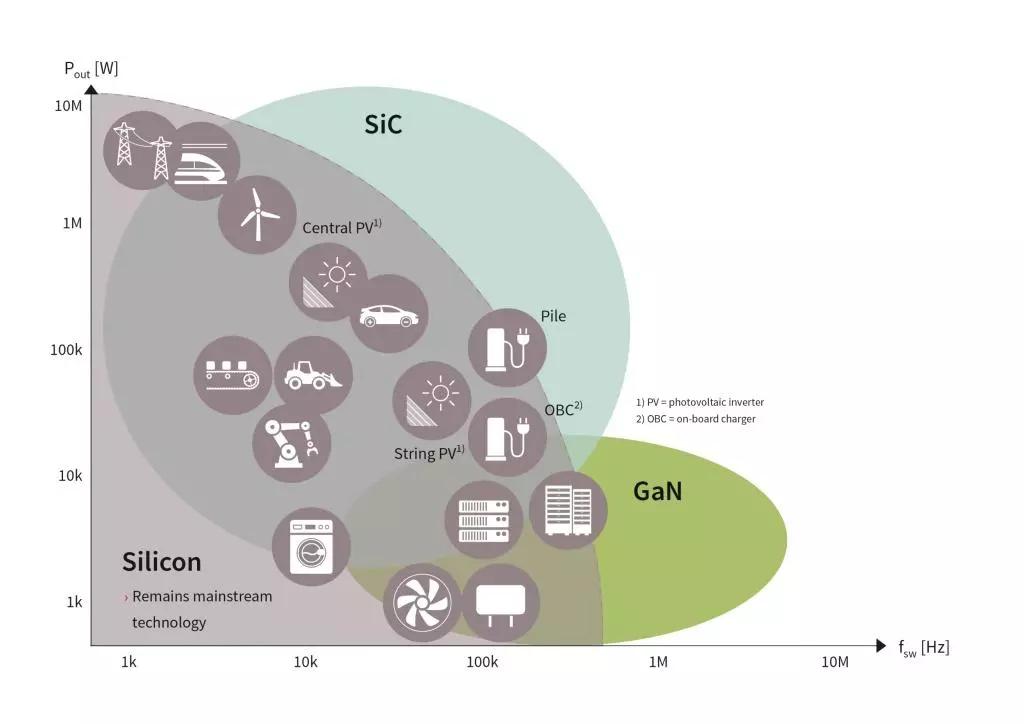

4. Njengesixhobo se-semiconductor

I-semiconductor yesizukulwana sesithathu yimathiriyeli engundoqo kunye necandelo le-elektroniki elixhasa ukutsha, uphuhliso, ukuguqulwa kunye nokuphuculwa kwezixhobo zokukhusela zelizwe, unxibelelwano lwe-5G lweselula, i-Intanethi yamandla, izithuthi zamandla amatsha, ukuhamba ngololiwe kunye namanye amashishini. Ngenxa yendima yayo ebalulekileyo kukhuseleko lwesizwe, ukwenziwa kwezinto ngobukrelekrele, ukuphuculwa kwemizi-mveliso, ugcino lwamandla kunye nokunciphisa ukukhutshwa kwezinto ezikhutshwayo kunye nezinye iimfuno eziphambili zeqhinga, iye isiba yindawo yobugcisa yokulawula kukhuphiswano kwihlabathi.

I-SiC, njengommeli oqhelekileyo wezixhobo ze-semiconductor yesizukulwana sesithathu, ngoku yenye yezona zinto zivuthiweyo kwaye zisetyenziswa ngokubanzi i-bandgap semiconductor imathiriyeli kwitekhnoloji yokuvelisa ikristale kunye nokwenziwa kwesixhobo. Yenze imathiriyeli yehlabathi, isixhobo, kunye nekhonkco leshishini lesicelo. Yimathiriyeli efanelekileyo ye-semiconductor yobushushu obuphezulu, i-high-frequency, ukumelana nemitha, kunye nosetyenziso lwamandla aphezulu. Ngenxa yokuncipha okubonakalayo kokusetyenziswa kwamandla kwezixhobo zombane, izixhobo zamandla e-silicon carbide zikwabizwa ngokuba "zizixhobo zamandla ohlaza" eziqhuba "inguqu yamandla entsha".

5. Ukomeleza kunye ne-arhente yokuqina

Ukongeza kwezi zicelo zingentla, i-silicon carbide whiskers okanye i-silicon carbide fibers isetyenziswe ngokubanzi njengeyona ndlela ibalaseleyo yokomeleza kunye ne-ejenti eqinisayo kwizinto ezidityanisiweyo ezinezixhobo ezisekwe kwintsimbi okanye kwi-ceramic kumacandelo anjengoomatshini, ubunjineli bekhemikhali, ukhuselo lwelizwe, amandla kunye nokhuseleko lokusingqongileyo.

Ixesha lokuposa: Mar-22-2025