Kwindawo yoshishino apho ubushushu obuphezulu, ukubola, kunye nokunxiba kuhlangana, ingxaki yokutshintshwa rhoqo kwemibhobho yentsimbi yesintu yophulwe ngumbhobho omtsha wezinto eziphathekayo -imibhobho ye-silicon carbide ekwaziyo ukunxiba, kunye neempawu zabo ezikhethekileyo zezinto eziphathekayo, ziye zabangela ukuguqulwa kwezobuchwepheshe kwinkqubo yokuhanjiswa kwintsimi yezoshishino.

1, Ukusebenza okugqwesileyo ngaphaya kwemida yezinto zemveli

Imibhobho ye-Silicon carbide enganyangekiyo ibonise iiparameters zokusebenza ezimangalisayo kukuqinisekiswa kwebhubhoratri: ubulukhuni beVickers be-2800HV bunokumelana nokukhukuliseka okuqhubekayo kwisanti yedayimane, kunye neemeko zokuthutha umgubo wamalahle kwizityalo zamandla okushisa, ubomi babo benkonzo buphantse buphindwe ka-15 ubude kunemibhobho ye-alloy yendabuko.

Kwimeko yovavanyo lobushushu obugqithisileyo, imibhobho ye-silicon carbide igcina imfezeko yolwakhiwo kubushushu obuphezulu be-1350 ℃, kunye ne-coefficient yokwandisa i-thermal kuphela kwisithathu sentsimbi engenasici. Ngokweemeko zesicelo, ekuthuthweni okuqhubekayo kweengqungquthela zetsimbi eziphezulu zokushisa, umbhobho usebenze ngokuqhubekayo kwiiyure ze-8000 ngaphandle kokuguqulwa okanye ukuqhekeka.

Ukuphendula kumceli mngeni oqinileyo we-corrosion kwishishini lemichiza, izinto ze-silicon carbide zisebenza ngokugqwesileyo kwi-acid egxininisiweyo ye-sulfuric. Idatha ibonisa ukuba phantsi kweemeko ezifanayo zokusebenza, ubomi benkonzo ye-silicon carbide imibhobho yi-8.2 amaxesha eepayipi ze-titanium alloy.

2, Ukuphumelela kweteknoloji kwizicelo zeshishini elinqamlezayo

Kumgca wokuvelisa izinto ezintle ze-electrode kwiibhetri ze-lithium, i-silicon carbide imibhobho eqondileyo ixazulula ingxaki yokuthutha kwinkqubo yokubala yokushisa ephezulu. Iimpawu zayo ezikhaphukhaphu ziphucula kakhulu ukusebenza kakuhle kofakelo, kunye noyilo olukhethekileyo lokuqhuba, ukuphelisa ngempumelelo iingozi zombane omileyo kwinkqubo yokuvelisa.

Ukusetyenziswa kwibala lemigodi kuyimpumelelo enkulu: Emva kokuba umzi-mveliso we-copper ore beneficiation wamkele imibhobho edityanisiweyo yesilicon carbide, umjikelo wogcino lwenkqubo yokuhanjiswa kodaka uye wandiswa kakhulu, nto leyo eyasindisa kakhulu iindleko zokuyigcina.

3, Ukuziphendukela kwemvelo okuqhubekayo kweenkqubo zokuvelisa ezichanekileyo

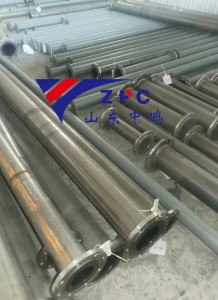

Umbhobho odityanisiweyo weemitha ezi-2 owenziwe kusetyenziswa itekhnoloji yereaction sintering uqhawula imida yobungakanani beendawo zeseramic eziqhelekileyo. Ngolawulo lwenkqubo ye-gradient sintering, inqanaba lomatshini oluchanekileyo lwempazamo yodonga lombhobho luyacuthwa.

Okwangoku, sisekwe kwintsebenziswano yeshishini lesikolo kunye nokusebenzisana neeyunivesithi eziphezulu ukuphuhlisa umgangatho ophezulu weemveliso ze-silicon carbide ceramic ezihlangabezana ngcono neemfuno ezahlukeneyo zabasebenzisi, kubandakanywa imibhobho ye-silicon carbide yokunxiba.

Kwixesha elitsha lemizi mveliso, imibhobho ye-silicon carbide enganyangekiyo ayisesiso isisombululo nje sokutshintsha izinto, kodwa icandelo eliphambili eliqhuba uphuculo olukrelekrele lwamashishini enkqubo. Ukuguqulwa kwezinto eziphathekayo, ukusuka kuthutho lwempahla yeefektri ezihlakaniphile ukuya kumacandelo angundoqo ezixhobo zamandla amatsha, ichaza ngokutsha imigangatho yokuthembeka yokuhanjiswa kwefektri. Siyaqhubeka nokulima izinto ezintsha kwaye sizibophelele ekuboneleleni izisombululo ezilungiselelwe amashishini ahlukeneyo, ukunceda abathengi ukwakha iinkqubo zokuvelisa ezisebenzayo nezizinzileyo.

Ukuba unomdla kwiimveliso zethu, nceda undwendwele [Shandong Zhongpeng] ngolwazi olungakumbi lwemveliso, okanye ufowunele (+86)15254687377 ukwenza idinga lokuxilongwa ngokufanelekileyo kwamandla kumgca wemveliso - masisebenze kunye, sifezekise intsebenziswano yokuphumelela, kwaye siqalise isahluko esitsha kwintsimi yezoshishino.

Ixesha lokuposa: Apr-01-2025