1. Ukuchasa ukuMdla

FGD imilomoIsebenza kwindawo enomhlwa kakhulu equlethe iioksidi zesulfure, iikloridi, kunye nezinye iikhemikhali ezinobundlobongela. I-Silicon carbide (i-SiC) i-ceramic ibonisa ukuxhathisa okungaqhelekanga kwe-corrosion kunye ne-0.1% yokulahleka kobunzima kwi-pH 1-14 isisombululo (ngovavanyo lwe-ASTM C863). Xa kuthelekiswa nensimbi engenasici (i-PREN 18-25) kunye ne-nickel alloys (PREN 30-40), i-SiC igcina ingqibelelo yesakhiwo ngaphandle kwe-pitting okanye i-corrosion corrosion cracking nakwi-acids concentrated kumaqondo okushisa aphezulu.

2. Uzinzo lobushushu obuphezulu

Amaqondo obushushu asebenzayo kwiinkqubo zokususa irhasi ye-flue emanzi aqhele ukuba phakathi kwe-60-80°C kunye nezikhonkwane ezingaphezulu kwe-120°C. I-ceramic ye-SiC igcina i-85% yamandla ayo obushushu begumbi kwi-1400 ° C, i-alumina ceramics egqwesileyo (ilahlekelwa yi-50% yamandla nge-1000 ° C) kunye neentsimbi ezixhathisa ukushisa. I-thermal conductivity (120 W / m·K) yenza ukutshatyalaliswa kobushushu okusebenzayo, ukuthintela ukwakhiwa koxinzelelo lwe-thermal.

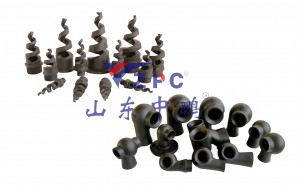

3. Nxiba ukuxhathisa

Ngobulukhuni beVickers obungama-28 GPa kunye nokuqina kokwaphuka kwe-4.6 MPa·m¹/², i-SiC ibonisa ukongamela ukhukuliseko oluchasene namasuntswana othuthu lwempukane (Mohs 5-7). Iimvavanyo zentsimi zibonisa i-nozzles ye-SiC igcina i-<5% inxiba emva kweeyure zenkonzo ye-20,000, xa kuthelekiswa ne-30-40% yokugqoka kwimibhobho ye-alumina kunye nokungaphumeleli okupheleleyo kweentsimbi ezifakwe kwi-polymer kwiiyure ze-8,000.

4. Iimpawu zokuhamba

Umphezulu ongemanzi we-reaction-bonded SiC (i-angle yoqhagamshelwano> 100 °) yenza ukuchithwa okuchanekileyo kwe-slurry kunye namaxabiso e-CV <5%. I-ultra-smooth surface (i-Ra 0.2-0.4μm) iyanciphisa uxinzelelo lwe-15-20% xa kuthelekiswa nemibhobho yesinyithi, ngelixa igcina i-coefficients ezinzileyo yokukhupha (± 1%) ngaphezu kokusebenza kwexesha elide.

5. Ukugcinwa lula

I-inertness yeekhemikhali ye-SiC ivumela iindlela zokucoca ezinobundlobongela kubandakanya:

-Ijethi yamanzi enoxinzelelo oluphezulu (ukuya kuthi ga kwiibhari ezingama-250)

-Ukucoca kwe-ultrasonic kunye nezisombululo ze-alkaline

- Ukuvala inzala ngomphunga kwi-150°C

Ngaphandle komngcipheko wokuthotywa komphezulu oqhelekileyo kwi-polymer-lined okanye i-coated metal nozzles.

6. I-Lifecycle Economics

Ngelixa iindleko zokuqala zemibhobho ye-SiC ziyi-2-3 × ephezulu kune-standard 316L yensimbi engenasici, ubomi babo benkonzo ye-8-10 yeminyaka (vs 2-3 iminyaka yesinyithi) inciphisa ukutshintshwa rhoqo ngama-70%. Iindleko zobunini zizonke zibonisa ukonga kwe-40-60% kwithuba leminyaka eli-10, kunye ne-zero downtime yokulungiswa kwendawo.

7. Ukuhambelana kokusingqongileyo

I-SiC ibonisa ukusebenza okungenakulinganiswa kwiimeko ezinzima:

- Ukuxhathisa isitshizi setyuwa: 0% utshintsho ubunzima emva 5000hr uvavanyo ASTM B117

- Ukusebenza kwindawo ene-asidi yombethe: Imelana ne-160°C umphunga we-H2SO4

-Ukumelana nokothuka kweThermal: Isinda kwi-1000°C→25°C imijikelo yokucima

8. Iipropati ezichasene nokulinganisa

Ubume be-athomu e-covalent ye-SiC yenza indawo engasebenziyo kunye namazinga okulinganisa ama-80% angaphantsi kunezinye iindlela zetsimbi. Izifundo ze-Crystallographic zityhila ukuba i-calcite kunye ne-gypsum deposits zenza iibhondi ezibuthathaka (i-adhesion <1 MPa) kwi-SiC ngokumelene> ne-5 MPa kwiintsimbi, okwenza kube lula ukususwa koomatshini.

Ukuqukumbela kwezobuGcisa

I-Silicon carbide ceramic ivela njengolona khetho lufanelekileyo lwemathiriyeli ye-FGD imilomo ngovavanyo olubanzi lokusebenza:

- I-10 × ubomi benkonzo obude kunezinye iindlela zetsimbi

- 92% ukucuthwa kulondolozo olungacwangciswanga

- I-35% yokuphucula ukusebenza kakuhle kokususa i-SO2 ngokusebenzisa iipateni zokutshiza ezingaguqukiyo

- Ukuthotyelwa ngokupheleleyo kwe-EPA 40 CFR iSigaba sama-63 semigangatho yokukhupha

Ngobuchule obuqhubela phambili bokuvelisa obufana nenqanaba lolwelo lokuntywila kunye nokwaleka kweCVD, imilomo yeSiC yesizukulwana esilandelayo ifezekisa umphezulu we-sub-micron kunye neejiyometri ezintsonkothileyo ebezingafumaneki ngaphambili kwiiseramics. Olu tshintsho lwetekhnoloji lubeka i-silicon carbide njengeyona nto ikhethwayo kwisizukulwana esilandelayo senkqubo yokucoca igesi yeflue.

Ixesha lokuposa: Mar-20-2025