I-silicon carbide (SiC) iiseramikhiziyaziwa ngamandla azo amangalisayo, ukumelana nobushushu, kunye nokuqina. Ezi zakhiwo zizenza zilungele ukusetyenziswa kwiindawo ezinzima, njengeenjini ze-aerospace okanye oomatshini bemizi-mveliso. Kodwa zenziwa njani kanye ezi zixhobo zihambele phambili? Masiyicalule inkqubo inyathelo ngenyathelo.

1.Ukulungiswa kwezinto ezikrwada

Yonke iqala nge-silicon carbide powder ecocekileyo ephezulu. Cinga oku "njengomgubo" wokubhaka i-ceramic "ikeyiki."Ukuphucula iimpawu zemathiriyeli yokugqibela, izixa ezincinci zezongezo-ezifana ne-aluminium oxide okanye i-boron compounds-zixutywe.

2. Ukubumba iCeramic

Umgubo uguqulwa ube yifomu enokubunjwa. Zimbini iindlela eziqhelekileyo ezisetyenziswayo:

Ukucinezela: Umgubo uxinzelelwa kwimo ethile usebenzisa uxinzelelo oluphezulu, olufana nokuhlanganisa ikhephu kwibhola yekhephu.

Isitofu sokubumba: Umgubo uxutywa nesibophelelo sexeshana (njenge-wax) ukwenza umxube ofana nentlama, othi utofwe kwimibumbo yeemilo ezintsonkothileyo.

Kweli nqanaba, izinto zisebuthathaka-njengomfanekiso oqingqiweyo wesanti eyomileyo-kwaye kufuneka "ubhakwe" ukuze womelele.

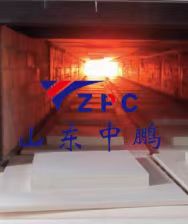

3. Inkqubo yeSintering

Kulapho kwenzeka khona umlingo. I-ceramic ebunjiweyo ifudunyezwa kwiziko elikhethekileyo kumaqondo obushushu aphezulu kakhulu (kaninzi ngaphezu kwe-1,800 ° C). Ngexesha le-sintering, izinto ezimbini eziphambili zenzeka:

I-Particle Bond: Iinkozo ze-silicon carbide zikhula ngokusondeleyo, zisusa izithuba kwaye zenze isakhiwo esomeleleyo.

Umsebenzi wezongezelelo: Iikhompawundi ezongeziweyo zinyibilika kancinane, zenza "ibhulorho" phakathi kwamasuntswana ukomeleza ukuqina.

Imekobume engaphakathi kweziko ilawulwa ngenyameko—maxa wambi izaliswe ziigesi ezingasebenziyo—ukuze kuthintelwe ukusabela okungafunwayo.

4. Ukugqiba ukuchukumisa

Emva kokucoca, i-ceramic inokuthi iqhube unyango olongezelelweyo ukulungisa ukusebenza kwayo:

Ukukhazimliswa:Kukusetyenziswa okudinga umphezulu ogudileyo (umzekelo, izitywina okanye iibheringi).

Ukwaleka: Umaleko obhityileyo okhuselayo (ofana nesilicon nitride) unokongezwa ukuqinisa ukuxhathisa ukunxiba.

Machining: Ukusika ngokuchanekileyo okanye ukugrumba ukufikelela kwimilinganiselo yokugqibela.

Kutheni Le nkqubo Ibalulekile

Imfihlelo yamandla e-silicon carbide ilele kwindlela iiathom zayo ezihlangana ngayo ngexesha lokuntywila. Inkqubo yobushushu obuphezulu yenza inethiwekhi yeebhondi ze-silicon-carbon ezomeleleyo, ezikwazi ukumelana nobushushu, ukubola kunye noxinzelelo lomzimba. Izongezo kunye nolawulo oluchanekileyo lobushushu liqinisekisa ukuba imveliso yokugqibela ayinzima nje kuphela kodwa yomelele ngokwaneleyo ukumelana nokuqhekeka.

UMfanekiso Omkhulu

Ukusuka kwiiinjini zomphetho ukuya kwiinkqubo zolawulo longcoliseko, iiseramics zesilicon carbide zidlala indima ebalulekileyo kubuchwephesha bale mihla. Ngelixa inkqubo yokuvelisa intsonkothile, yile bhalansi ngononophelo yesayensi kunye nobunjineli ejika umgubo olula ube yinto ekwaziyo ukumelana nezona meko zinzima.

Njengoko uphando luqhubela phambili, iindlela ezintsha-ezifana noshicilelo lwe-3D lweekeramics-ziyavela, zithembisa usetyenziso oluyintsha ngakumbi kwesi sixhobo singaqhelekanga.

Ixesha lokuposa: Mar-19-2025