I-silicon carbide kunye ne-silicon nitride inokumanzisa kakubi ngesinyithi esinyibilikisiweyo. Ngaphandle kokungeniswa yi-magnesium, nickel, i-chromium alloy kunye nentsimbi engatyiwayo, ayinakumanzi kwezinye iintsimbi, ngoko ke inokumelana nokugqwesa okugqwesileyo kwaye zisetyenziswa kakhulu kwishishini le-aluminium electrolysis.

Kweli phepha, ukuxhathisa kwe-corrosion ye-silicon carbide i-R-SiC kunye ne-silicon nitride edibeneyo ye-silicon carbide i-Si3N4-SiC kwi-hot-circulating Al-Si alloy melts yaphandwa ukusuka kwiindawo ezininzi.

Ngokwedatha yovavanyo yamaxesha e-9 yebhayisekile eshushu ye-1080h kwi-495 ° C ~ 620 ° C i-aluminium-silicon alloy melt, ezi ziphumo zohlalutyo zilandelayo zifunyenwe.

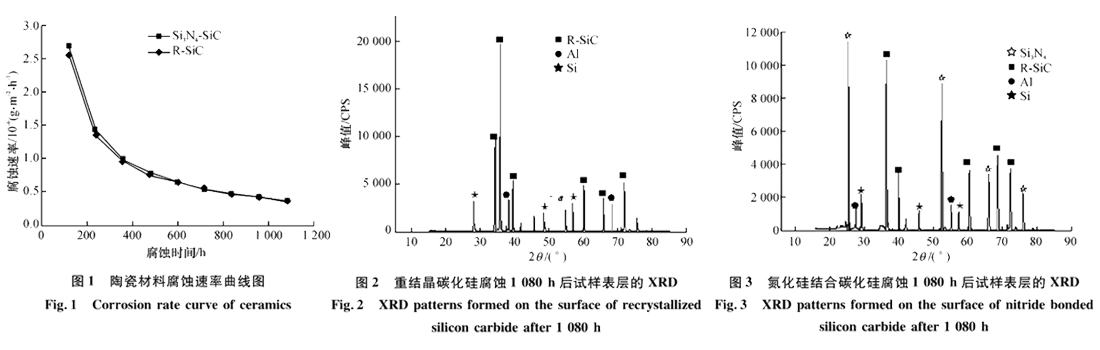

Iisampulu ze-R-SiC kunye ne-Si3N4-SiC zanda ngexesha lokubola kwaye izinga lokubola liyehla. Izinga lokumhlwa lihambelana nobudlelwane belogarithmic bokuthomalalisa. (umzobo 1)

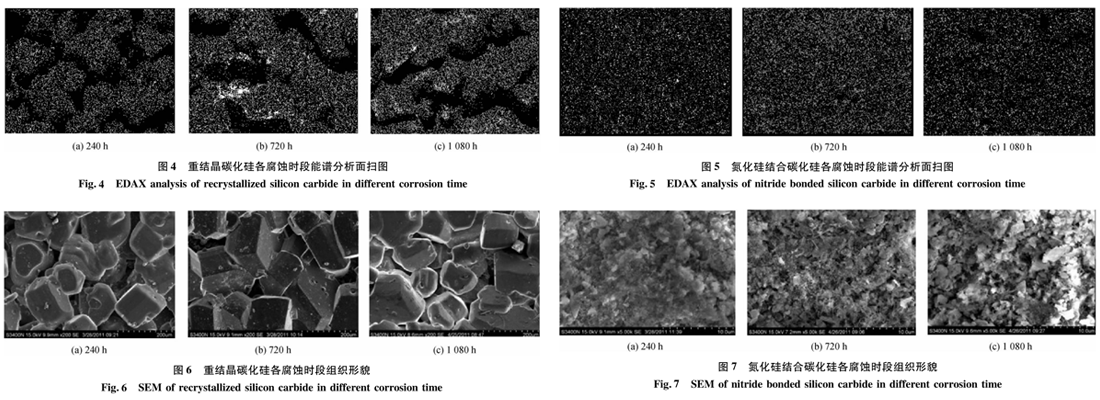

Ngohlalutyo lwe-spectrum yamandla, iisampuli ze-R-SiC kunye ne-Si3N4-SiC ngokwazo azinayo i-aluminium-silicon; kwipatheni ye-XRD, inani elithile le-aluminiyam-silicon peak yi-surface-residual aluminiyam-silicon alloy. (Umfanekiso 2 – umzobo 5)

Ngokusebenzisa uhlalutyo lwe-SEM, njengoko ixesha lokubola linyuka, isakhiwo esipheleleyo se-R-SiC kunye ne-Si3N4-SiC iisampulu zikhululekile, kodwa akukho monakalo ocacileyo. (Umfanekiso 6-Umfanekiso 7)

Uxinzelelo lomphezulu σs/l>σs/g yojongano phakathi kolwelo lwe-aluminiyam kunye ne-ceramic, i-engile yokumanzisa θ phakathi kojongano yi>90°, kunye nojongano phakathi kolwelo lwe-aluminiyam kunye ne-sheet ceramic material ayimanzi.

Ke ngoko, izixhobo ze-R-SiC kunye ne-Si3N4-SiC zigqwesile ekuxhathiseni ukubola ngokuchasene ne-aluminium silicon inyibilika kwaye inomahluko omncinci. Nangona kunjalo, ixabiso lezinto ze-Si3N4-SiC liphantsi kwaye lisetyenziswe ngempumelelo iminyaka emininzi.

Ixesha lokuposa: Dec-17-2018