Well-designed Sand Blasting Room - RBSC Heat Exchanger – ZhongPeng

Well-designed Sand Blasting Room - RBSC Heat Exchanger – ZhongPeng Detail:

The high temperature strength, oxidation resistance, high tensile strength, corrosion-resistance, good thermal conductivity and thermal shock resistance of Reaction Bonded SiC enables the manufacturer of low mass kiln supports. Kiln products include thin walled beams, posts, setters, burner nozzles and rolls. The components lower the thermal mass of kiln cars, result in energy savings and provide the possibility for faster product throughput.

ZPC factory is widely appraised for delivering premium quality silicon carbide radiant tube and burner nozzle in the market. These are used in various industries such as shuttle kiln, roller hearth kiln and tunnel kiln. In addition, these are also used in several industrial kilns, which are fuel oil and fuel gas. Further, these are also used in many domestic and foreign companies. These are constructed with the help of the latest machinery & equipment. Their various characteristics are as follows:

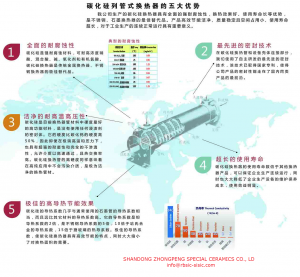

Ceramic heat exchangers are resistant to fatigue, corrosion, acid, thermal shock, water/steam hammer and other mechanical abuse. While the ZPC® ceramic is universally corrosion and erosion resistance, the ZPC® SiSiC ceramic is suitable for processing mixed acids, sulfuric acid, hydrochloric acid, phosphoric acid, nitric acid, waste acids and chlorinated hydrocarbons and also for corrosive condensing, vaporizing, absorbing, heating and cooling applications.

Product detail pictures:

Related Product Guide:

Understanding of Metal Tubing within Ceramic lining

SiC FGD desulphurization nozzles

Well-designed Sand Blasting Room - RBSC Heat Exchanger – ZhongPeng, The product will supply to all over the world, such as: , , ,

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.