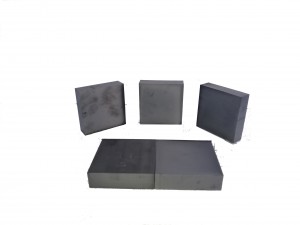

Wear resistant silicon carbide ceramic tiles

ZPC reaction bonded silicon carbide (SiSiC or RBSIC) is an ideal wear resistant material, which is

especially suitable for the strong abrasive,coarse particles, classification, concentration, dehydration and the

other operations. It is widely used in mining industry, steel industry, coral processing industry, chemical

industry, raw material-making industry, mechanical sealing, surface sandblasted treatment and reflector etc.

Thanks to the excellent hardness and abrasive resistance, it can effectively protect the part where need wear

protection, so as to prolong the service life of the equipment.

■ Specifications:

|

Item |

Unit |

Data |

|

Temperature of application |

℃ |

1380℃ |

|

Density |

G/cm3 |

>3.02 |

|

Open porosity |

% |

<0.1 |

|

Bending strength -A |

Mpa |

250 (20℃) |

|

Bending strength -B |

MPa |

280 (1200℃ ) |

|

Modulus of elasticity-A |

GPa |

330(20℃) |

|

Modulus of elasticity -B |

GPa |

300 ( 1200℃ ) |

|

Thermal conductivity |

W/m.k |

45 (1200℃ ) |

|

Coefficient of thermal expansion |

K-1 ×10-6 |

4.5 |

|

Rigidity |

/ |

13 |

|

Acid-proof alkaline |

/ |

excellent |

■ Available Shape and sizes:

Thickness: from 6mm up to 25mm

Regular Shape: SISIC plate, SISIC Pipe, SiSiC Three Links, SISIC Elbow, SISIC Cone Cyclone.

Remark: Other sizes and shape are available upon requests.

■ Packaging:

In carton box, packed in fumigated wooden pallet with net weight 20-24MT/20′FCL.

■ Key benefits:

1. Excellent wear resistance, impact resistance and corrosion resistance;

2. Excellent flatness and excellent temperature resistance up to 1350℃

3. Easy installation;

4. Longer service life (is about 7 times more than that of alumina ceramic and 10 times more than that of

polyurethane

Pattern of angle impact abrasion Low angle sliding abrasion

When flow of abrasive material hits a wear surface at a shallow angle or passes parallel to it, the type of wear that occurs in friction is called sliding abrasion.

Advanced silicon carbide ceramics provide wear resistance and corrosion resistance ceramic tiles and lining. These products have been proven wear of equipment in conveying, processing, and storage process. Our tiles can be produced with thickness from 8 to 45mm. it is important to ensure that you can get the required products. SiSiC: Moh’s hardness is 9.5 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. It is 4 to 5 times stronger than nitride bonded silicon carbide. The service life is 5 to 7 times longer than alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. Wear resistant ceramic lining is conductive to make improvement of the production performance, the working efficiency, the reduction of maintenance costs and the increase profits.

Precision ceramics have material knowledge, applied expertise and engineering skills. This can effectively ensure that the best solutions are offered to our customers. Silicon carbide ceramic tiles and lining are often used in applications such as cyclones, tubes, chutes, hoppers, pipes, conveyor belts and production systems. In the system, there are moving objects sliding on the surface. When the object slides on a material, it slowly wears the parts away until nothing remains. In high wear environments, this can happen frequently and cause a lot of expensive problems. The main structure is retained by using a very hard material, such as silicon carbide ceramics and alumina ceramics as a sacrificial lining. At the same time, silicon carbide ceramics can endure longer wear before it needs to be replaced, the silicon carbide ceramic service life is 5 to 7 times longer than alumina material .

Wear Resistant Silicon Carbide Ceramic Tiles & Lining Properties:

Chemical resistant

Electrically insulative

Mechanical erosion & Abrasion resistant

Replaceable

Advantages of Ceramic Wear Resistant Tiles & Linings:

Can be used where tight tolerances or thin linings are required

Can be used to resurface existing wear prone areas

Can be used with multiple attachment methods like welding and adhesives

Custom designed for specific applications

Highly corrosion resistant

Lightweight wear reduction solution

Protects moving parts that are subject to high wear environments

Significantly outlasts & outperforms wear reduction solutions

Ultra-high maximum use temperature of up to 1380°C

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.