Nasadka peskovaya-Material- karbid kremniya

Nasadka peskovaya-Material- karbid kremniya

| SiC & SiSiC - Silikon karbidning texnik ma'lumotlari | ||

| Xususiyatlari | SiC (99%) | SiSiC |

| Zichlik (g/cc) | 3,15 ±0,03 | 3.2 |

| G'ovaklik % (sub-mikron) | 3,15 ±0,03 | 0,00% |

| Maksimal harorat (°C) | 410 | 1150 ° S |

| Bukilish kuchi (MPa) @ RT | 2800 | 800 |

| Weibull moduli | 3970 (560) | 15-30 |

| Elastik modul (GPa) | 4 | 310 |

| Puasson nisbati | 0,21 | 0,27 |

| Qattiqlik HV (0,3) Kg/mm2 | 4×10-6 | 1800 |

| Sinishi chidamliligi (MPam1/2) | 120 | 5.5 |

| Abraziv aşınma qarshilik parametri | 0,67 | 1110 |

| Termal kengayish koeffitsienti. 10-6/C; (RT-1000 C) | 1500 | 3.1 |

| Mulk qiymatlari taxminiy xarakterga ega va ular spetsifikatsiya sifatida qabul qilinmasligi kerak. | ||

Silikon karbidli keramika (RBSC/SiSiC liners) - YouTube https://www.youtube.com/watch?v=Caqp0Rrfhgo

Izvesten sposob zashchity vnutrenney ra bochey poverxnosti gidrotsiklon fasonnym kamennym litem. Futerovku osushchestvlyayut 1O ukladkoy i zakrepleniem v korpuse gidrotsiklona s pomoshchyu tsementnogo rastvora otdelnyh nabornyx kamneltyx elementov. Nedostatki etoho sposoba vĐ” vysokaya trudoemkost montaj elementov iz-za netochnosti ix geometrik formalari, katta trudnosti demontaja iznoshennoy futerovki. gidrotsiklona, uhudshaet texnologicheskie pokazateli ego raboty, snijaet srok slujby futerovki v tselom.

B mohs, RBSiC keramika prevyshaet 9, kotoryy blizok k tverdosti almazov.srok slujby sic keramika – v 10 dan katta, chem u poliuretanovoy obolochkoy.

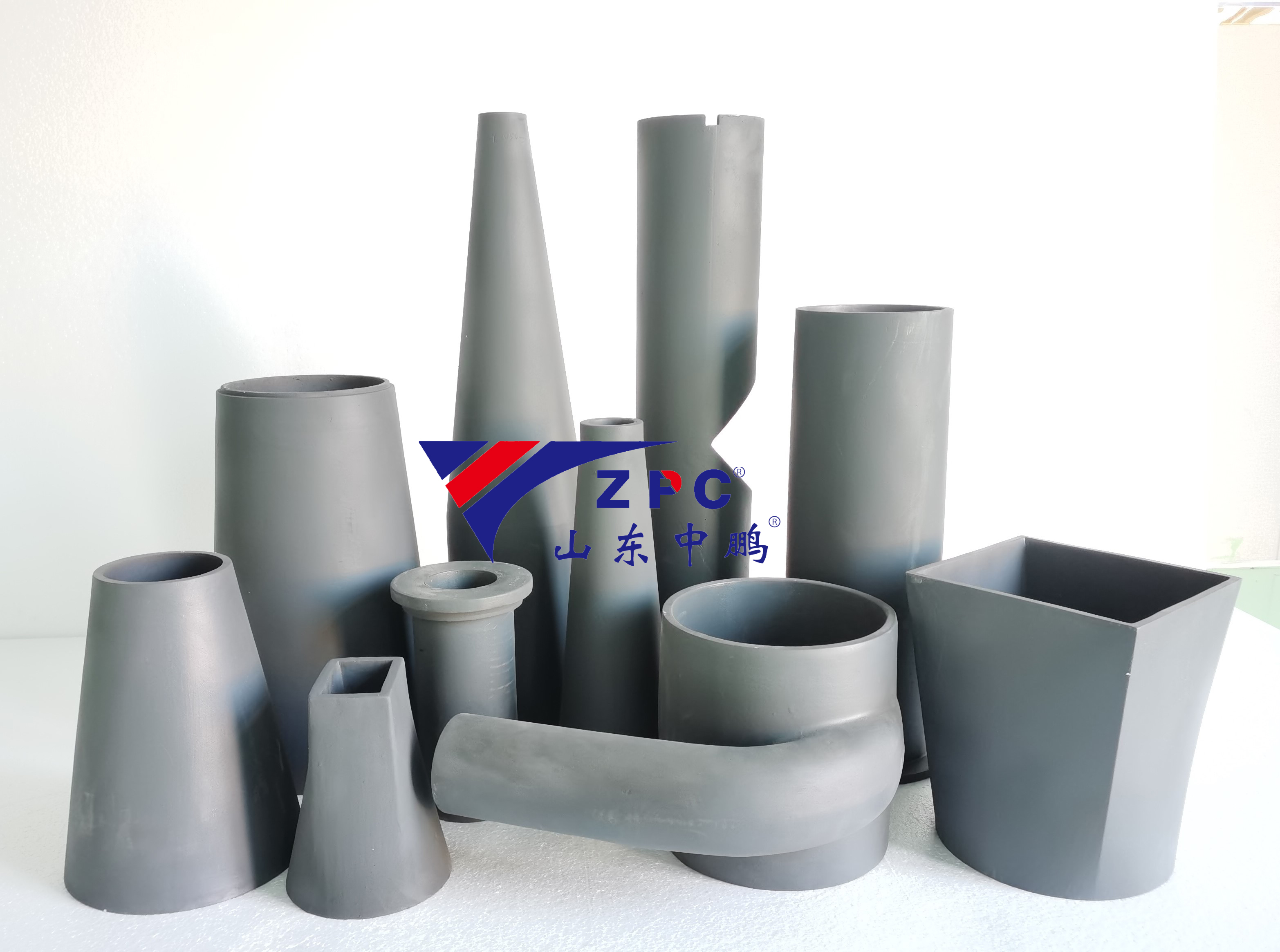

ZPC razrabatyvaet va proizvodit vysokoeffektyvnye tsiklony, gidrotsiklonnye, gidrotsiklonnye vkladyshi va vspomogatelnye komponentlar o'z ichiga o'tkazuvchanlik keramicheskyh materiallardan foydalanish uchun ekstremal abrazivnyh va agressiv sredah.

Prodvinutaya keramika RBSiC s tverdostyu to 3500 Vickers bir necha oddiy materiallardan iborat bo'lib, uni o'z ichiga oladi. Oni znachitelno bolee iznosostoykie, chem nerjaveyushchie stali, ni-tverdye va stellitovye materiallar, traditsionno ispolzuemye pri proizvodstve etix tipov gidrotsiklonov.

Nashi gidrotsiklony prednaznacheny razdeleniya zahvachennyh tverdyx veshchestv iz bolshinstva jidkostey v atmosfernyh va vysokotemperaturnyx abrazivnyh va agressivnyx sredah.

My postavlyaem mno obraztsov peredogogo SiC-keramicheskogo gidrotsiklona uchun nefti, shaxte va dori vositalari ishlab chiqarishda foydalanish.

| Korroziya sinovi natijalari | |||

| Sinov muhiti* | Korroziv vazn yo'qotish, mg/sm2/yil | ||

| Konsentratsiya reaktivi, og'irligi% | Harorat | SiC | SiSiC |

| 98% H2SO4 | 100°C | 1.5 | 50 |

| 50% NaOH | 100°C | 2.5 | >1000 |

| 53% HF | 100°C | <0,2 | 7 |

| 85% H3PO4 | 100°C | <0,2 | 8 |

| 70% HNO3 | 100°C | <0,2 | 0,5 |

| 45% KOH | 100°C | <0,2 | >1000 |

| 25% HCl | 100°C | <0,2 | 0,9 |

| 10% HF plyus 57% HNO3 | 25°C | <0,2 | >1000 |

| * Barcha kislotalarda 125-300 soat sinov va doimiy aralashtiriladi. | |||

Shandong Zhongpeng Special Ceramics Co., Ltd Xitoydagi eng yirik silikon karbidli keramik yangi material echimlaridan biridir. SiC texnik keramika: Mohning qattiqligi 9 (New Mohning qattiqligi 13), eroziya va korroziyaga mukammal qarshilik, mukammal aşınma - qarshilik va oksidlanishga qarshi. SiC mahsulotining xizmat qilish muddati 92% alumina materialidan 4-5 baravar ko'p. RBSiC ning MOR ko'rsatkichi SNBSC dan 5-7 baravar ko'p, undan murakkabroq shakllar uchun foydalanish mumkin. Kotirovka jarayoni tez, yetkazib berish va'da qilinganidek va sifat hech kimdan kam emas. Biz doimo maqsadlarimizga intilamiz va qalbimizni jamiyatga qaytaramiz.