roala lithaele tsa ceramic tse hanyetsanang

![]()

Reaction bonded silicon carbide (SiSiC kapa RBSIC) ke thepa e sa sebetsaneng hantle, e leng

haholo-holo a loketse bakeng sa matla abrasive, mahoashe likaroloana, classification, mahloriso, dehydration le

lits'ebetso tse ling. E sebelisoa haholo indastering ea merafo, indasteri ea tšepe, indasteri ea ts'ebetso ea likorale, lik'hemik'hale

indasteri, indasteri ea ho etsa thepa e tala, ho tiisa ka mochini, kalafo e entsoeng ka lehlabathe le ho bonahatsa joalo-joalo.

Ka lebaka la boima bo babatsehang le khanyetso ea abrasive, e ka sireletsa ka katleho karolo eo ho hlokahalang ho apara

tshireletso, e le ho lelefatsa bophelo ba tšebeletso ea lisebelisoa.

U ka tseba joang le ho fumana lipoleiti tsa boleng bo holimo tsa silicon carbide, lithaele, li-liner?

Lithaele tse manganga tsa silicon carbide, li-liner, liphaephe li ntse li sebelisoa haholo indastering ea merafo.

Lintlha tse latelang ke tsa litšupiso tsa hau:

1. Foromo le ts'ebetso:

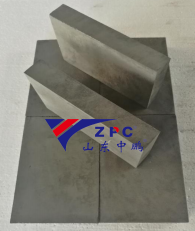

Ho na le mekhoa e mengata ea SiC 'marakeng. Re sebelisa litlolo tsa 'nete tsa Sejeremane. Litekong tsa laboratori tsa boemo bo holimo, sehlahisoa sa rona sa Khoholeho ea mobu ㎝³ tahlehelo e ka fihla ho 0.85 ± 0.01;

2. Ho thatafala:

Lithaele tsa SiC li hlahisoa ka ZPC: boima bo bocha ba Mohs: 14.55 ± 4.5 (MOR, psi)

3. Boima ba 'mele:

Tekanyo ea lithaele tsa ZPC SiC e ka ba 3.03+0.05.

4. Boholo le Bokaholimo:

Lithaele tsa SiC tse hlahisoang ka ZPC ntle le mapetsong le li-pores, tse nang le libaka tse bataletseng le likhutlo tse tiileng le likhutlo.

5. Lisebelisoa tsa ka hare:

Li-silicone carbide li-resistant liner / lithaele li na le lisebelisoa tse ntle le tse ts'oanang tsa kahare le kantle.

If any questions, please feel free to contact us: info@rbsic-sisic.com

■Litlhaloso:

| Ntho | Yuniti | Lintlha |

| Mocheso oa kopo | ℃ | 1380 ℃ |

| Botenya | G/cm3 | ~3.02 |

| Porosity e bulehileng | % | <0.1 |

| Matla a ho kobeha -A | Mpa | 250 (20℃) |

| Matla a ho kobeha -B | MPa | 280 (1200 ℃) |

| Modulus ea elasticity-A | GPA | 330(20℃) |

| Modulus ea elasticity -B | GPA | 300 (1200℃) |

| Thermal conductivity | W/mk | 45 (1200℃) |

| Coefficient ea katoloso ea mocheso | K-1 × 10-6 | 4.5 |

| Regidity | / | 13 |

| Alkaline e thibelang asiti | / | e kgabane |

■Sebopeho le boholo bo fumanehang:

Botenya: ho tloha ho 6mm ho isa ho 25mm

Sebopeho se Tloaelehileng: poleiti ea SISIC, Pipe ea SISIC, SiSiC Three Links, SISIC Elbow, SISIC Cone Cyclone.

Tlhokomeliso: Lisaese tse ling le sebopeho li teng ha u kopa.

■Sephutheloana:

Ka lebokoseng la mabokose, le phuthetsoe ka pallet ea lehong e tlositsoeng e nang le boima ba 20-24MT/20′FCL.

■Melemo ea bohlokoa:

1. Ho hanyetsa ka mokhoa o babatsehang, ho hanyetsa tšusumetso le ho hanyetsa kutu;

2. Botebo bo babatsehang le ho hanyetsa mocheso o babatsehang ho fihlela ho 1350 ℃

3. Ho kenya habonolo;

4. Bophelo bo bolelele ba tšebeletso (bo ka makhetlo a 7 ho feta ba ceramic ceramic le makhetlo a 10 ho feta ba

polyurethane

Paterone ea angle impact abrasion Ho khopama ha angle angle e tlase

Ha phallo ea thepa e hohlang e fihla sebakeng se sa tebang kapa e feta e bapileng le eona, mofuta oa moaparo o bang teng ha ho hohlana o bitsoa sliding abrasion.

Li-ceramics tsa silicon carbide tse tsoetseng pele li fana ka khanyetso ea ho roala le ho hanyetsa kutu lithaele tsa ceramic le lesela. Lihlahisoa tsena li netefalitsoe hore li na le lisebelisoa tsa ho tsamaisa, ho sebetsa le ho boloka. Lithaele tsa rona li ka hlahisoa ka botenya ho tloha ho 8 ho isa ho 45mm. ho bohlokoa ho etsa bonnete ba hore o ka fumana lihlahisoa tse hlokahalang. SiSiC: Ho thatafala ha Moh ke 9.5 (Bothata ba Moh e Ncha ke 13), e nang le khanyetso e babatsehang ea khoholeho ea mobu le ho bola, ho senya ho babatsehang - ho hanyetsa le ho thibela oxidation. E matla ka makhetlo a 4 ho isa ho a 5 ho feta nitride bonded silicon carbide. Bophelo ba tšebeletso ke linako tse 5 ho isa ho tse 7 ho feta lisebelisoa tsa alumina. MOR ea RBSiC ke 5 ho makhetlo a 7 ea SNBSC, e ka sebelisoa bakeng sa libopeho tse rarahaneng haholoanyane. Ho roala lesela la ceramic le sa sebetseng le sebetsa hantle ho ntlafatsa ts'ebetso ea tlhahiso, katleho ea ts'ebetso, phokotso ea litšenyehelo tsa tlhokomelo le phaello ea phaello.

Li-ceramics tse nepahetseng li na le tsebo ea lintho tse bonahalang, tsebo e sebelisitsoeng le tsebo ea boenjiniere. Sena se ka etsa bonnete ba hore tharollo e molemohali e fanoa ho bareki ba rona. Lithaele tsa silicon carbide ceramic le lining li atisa ho sebelisoa lits'ebetsong tse kang maholiotsoana, li-tubes, chutes, hoppers, liphaephe, mabanta a conveyor le mekhoa ea tlhahiso. Tsamaisong, ho na le lintho tse tsamaeang tse thellang holim'a metsi. Ha ntho e thella holim'a thepa, butle-butle e senya likarolo ho fihlela ho se letho le setseng. Libakeng tse phahameng tsa ho apara, sena se ka etsahala khafetsa 'me sa baka mathata a mangata a theko e boima. Mohaho o ka sehloohong o bolokoa ka ho sebelisa thepa e thata haholo, joalo ka silicon carbide ceramics le alumina ceramics e le lesela la sehlabelo. Ka nako e ts'oanang, li-ceramics tsa silicon carbide li ka tšoarella nako e telele pele li hloka ho nkeloa sebaka, bophelo ba tšebeletso ea silicon carbide ceramic bo bolelele ba makhetlo a 5 ho isa ho a 7 ho feta lisebelisoa tsa alumina.

Apara Lithaele tsa Ceramic tsa Silicon Carbide le Thepa ea Marang-rang:

Ho hanyetsa lik'hemik'hale

Motlakase oa ho itšireletsa

Ha ho na khoholeho ea metjhini le ho hahloa

E ka nkeloa sebaka

Melemo ea Lithaele le Lithaele tse Thibelang Keramic Wear:

E ka sebelisoa moo ho nang le mamello e thata kapa li-linens tse tšesaane li hlokahalang

E ka sebelisoa ho nchafatsa libaka tse seng li ntse li tloaetse ho roala

E ka sebelisoa ka mekhoa e mengata ea ho hokela joalo ka welding le likhomaretsi

Tloaelo e etselitsoeng lits'ebetso tse ikhethileng

E thibela ho bola haholo

Tharollo ea ho fokotsa ho roala ha bobebe

E sireletsa likarolo tse tsamaeang tse tlas'a maemo a holimo

E ipabola haholo ebile e sebetsa ho feta litharollo tsa phokotso ea liaparo

Mocheso o phahameng haholo oa tšebeliso o fihlang ho 1380°C

1, Semela sa tšepe le tšepe: 1, mochini oa sintering drum mixer lening 2, moqomo o phuthetsoe ka rabara ea ceramic 3, fan impeller 4, disc feeder, trough 5, coke hopper, converter bin, coke bin, leholiotsoana le bokellang lerole.

2, Setsi sa motlakase: 1. Mokotla oa leloala la leloala, leloala la leloala, sekoti sa leloala la lebelo le bohareng, setsoe sa phala ea phofo, moqosi oa lerōle la sefefo, silo, hopper 2, separator sa mashala, sepharolano sa phofshoana e mahoashe, sephatlalatsi sa leloala la mashala, sekoti se tsamaisang mashala 3, sekoti sa mashala sa borokho, setsi sa coal le milllet outlet. ea separasi sa phofo e mahoashe le e ntle, vollute exhauster ea phofo liphaephe tse nang le likarolo tse ngata tsa ceramic tse manganga le litsoe, licheso tsa ceramic, lifensetere tsa ceramic, li-impeller tsa ceramic, li-valve tsa ceramic, joalo-joalo; likarolo tse fapa-fapaneng tse sa tsoeng tse kang libolo tse sila, matsoho a rolara, li-disc tsa ho sila, lithaelese tsa disc, mehele e silang, libolo tsa nozzle le likarolo tse ling tse sa keneng bakeng sa limilone tsa mashala a lebelo le mahareng; liphaephe, li-damper tse sa tsoeng le li-fan tsa lintlha tse fapaneng tsa ho phunya le ho tlosa molora; libolo Mefuta eohle ea leloala e na le (kapa che) lithaele tsa bolt ea bolt, poleiti ea lining, pipe ea spiral, selikalikoe sa gear, bolo ea tšepe e tlase ea chromium alloy, joalo-joalo; lebili le otlang, poleiti e otlang, hook ea balebeli, lihlomo, separator, phaepe ea khase ea mocheso o phahameng oa mocheso oa sebopi, joalo-joalo bakeng sa leloala la mashala a fene; lisebelisoa tse hlokahalang bakeng sa mefuta e sa tšoaneng ea mechine e senyang.

3, Leloala la pampiri: 1. Peipi ea mashala e silafalitsoeng

Lihlahisoa le lits'ebeletso tsa mantlha: 1. Liphaephe tsa ceramic tse sa keneleng liindasteri: mefuta eohle ea ceramic e sa sebetseng le mocheso o phahameng e kentsoeng ka mashala a thuntsoeng, mehatla, liphaephe tsa lipalangoang tse senyehileng, setsoe, setsoe, secheso sa mashala se pshatlehileng, mochini oa leloala la mashala, sekoti sa polokelo ea mashala, sekoti sa polokelo ea mashala, sekoaelo sa mashala. moqomo oa ho roala oa merafo ea karohano ea makenete; 2. Apara fan ea ceramic e hanyetsanang: mefuta eohle ea mocheso o phahameng o hanyetsanang le mocheso o phahameng, o sa senyeheng, o thibelang ho bola ha mocheso oa fan le volute, ho kenyelletsa le centrifugal fan, axial flow fan, static blade, suction blade e khonang ho fetola fan, suction fan, exhauster ea phofo, fene ea sintering, fan ea karohano ea phofo, fene ea karohano ea phofo, fene ea ho tlosa lerōle, joalo-joalo. 3. Apara pompo ea lesela la ceramic le li-valve tse hanyetsanang: lesela la ceramic, pompo ea pompo, khetla, baffle, setsoe sa pipe, ho tlosoa molora oa pneumatic le valve ea phetisetso ea khase le lisebelisoa tsa mefuta e sa tšoaneng ea slurry, slag slurry, seretse, mehatla le mekhoa e meng ea lipalangoang. 4. Apara liphahlo tsa ceramic tse sa tsitsang: mefuta eohle ea liphahlo tsa ceramic tse sa keneleng mocheso le mocheso o phahameng le mastic li sebelisoa bakeng sa fan volute, pipe ea setsoe, mochini oa leloala, phala e mahoashe le e ntle ea karohano, chute, hopper le valve. 5. Apara lisebelisoa tsa karohano tsa makenete tse hanyetsanang: likarolo tsa phallo ea lisebelisoa tse fapaneng tse omeletseng le tse metsi tse sebetsanang le liminerale, ho kenyeletsoa moqomo oa karohano ea makenete, groove e tlase, chute, liphaephe, lipompo tse fapaneng tsa seretse, volute ea slurry pump, impeller, le liphaephe tse tsamaisang. 6. Theknoloji ea ho fafatsa ka holim'a metsi: ho sebelisa motlakase oa morao-rao oa machaba oa inverter pulse arc le sethunya sa ho fafatsa ka lebelo le phahameng la arc, lisebelisoa tse sa tšoaneng tsa tšepe tse sa tsitsang le tse thibelang ho bola li fafatsoa holim'a karolo ea tšepe ea tšepe ho etsa lera le sireletsang le thibelang kutu. E ka fana ka tšireletso e sebetsang bakeng sa mefuta eohle ea li-corrosion tsa matla a mahareng.

Shandong Zhongpeng ZPC ceramics ke khoebo e sebetsanang le tlhahiso ea lirafshoa tsa indasteri, haholo-holo e sebetsanang le R & D le tlhahiso ea lirafshoa tsa silicon carbide. Re ka sebetsana le lihlahisoa tsa ceramic ho ea ka lits'oants'o tsa hau, tse ikhethang ka tlhahiso ea boholo bo boholo, molamu oa ceramic o nepahetseng ka ho fetesisa, phala ea ceramic, selikalikoe sa ceramic, poleiti ea ceramic, flange ea ceramic, nozzle ea ceramic, le likarolo tse kholo tse sa keneng.

Shandong Zhongpeng Special Ceramics Co., Ltd ke e 'ngoe ea litharollo tse ncha tsa silicon carbide ceramic China. SiC tekheniki ea ceramic: Ho thatafala ha Moh ke 9 (Bothata ba Moh e Ncha ke 13), e nang le khanyetso e babatsehang ea khoholeho ea mobu le ho bola, ho senya ho hoholo - ho hanyetsa le ho thibela oxidation. Bophelo ba tšebeletso ea sehlahisoa sa SiC bo bolelele ba makhetlo a 4 ho isa ho a 5 ho feta 92% ea lisebelisoa tsa alumina. MOR ea RBSiC ke 5 ho makhetlo a 7 ea SNBSC, e ka sebelisoa bakeng sa libopeho tse rarahaneng haholoanyane. Ts'ebetso ea quotation e potlakile, thomello e joalo ka ha e ts'episitsoe 'me boleng ha bo na letho. Re lula re phehella ho phephetsa lipakane tsa rona le ho khutlisetsa lipelo tsa rona sechabeng.