Silicon carbide tube e sireletsang

Liindastering moo maemo a feteletseng a sokelang botšepehi ba lisebelisoa,silicon carbide (SiC) li-tubes tse sireletsanghlaha joalo ka tharollo ea motheo. Ho fapana le lisebelisoa tse tloaelehileng tsa tšireletso, li-tubes tsa SiC li kopanya mahlale a tsoetseng pele a mahlale le boenjiniere bo matla ho sireletsa lisebelisoa le lits'ebetso tsa bohlokoa. E na le melemo e latelang:

1. Tšireletso e sa Bapisoeng Maemong a Boraro

Li-tubes tse sireletsang tsa SiC li sebetsa e le mokhoa oa pele oa tšireletso libakeng tseo ho hloleha e seng khetho:

(1) Tšireletso ea Thermal: E mamella mocheso o tsitsitseng ho fihlela ho 1600 ° C, li-sensor tse sireletsang, li-thermocouples, kapa li-probes tse tsoang litšepe tse qhibilihisitsoeng, malakabe le plasma.

(2) Tšireletso ea lik'hemik'hale: Hanela ho bola ho tsoa ho acid (mohlala sulfuric, hydrochloric), alkalis, le likhase tse sebetsang tse kang chlorine kapa sulfur oxides.

Abrasion Resistance: Sireletsa khahlanong le likaroloana tse hoholehang libetheng tse nang le metsi, ligase tsa mashala, kapa mesebetsi ea merafo.

2. Ho nepahala le botsitso bakeng sa Litekanyo tse Bohlokoa

Lits'ebetsong tse phahameng tsa indasteri, ho nepahala ke ntho e ka sehloohong. Li-tubes tsa SiC li ntlafatsa ts'epahalo ka:

(1) Ho fokotsa Tšitiso ea Letšoao: Thepa e sa sebetseng e thibela ho senyeha ha motlakase ho li-sensor tsa elektroniki.

(2) Thermal Stability: Haufi le zero thermal deformation e netefatsa tatellano e tsitsitseng le ho nepahala ha tekanyo tlas'a ho fetoha ha mocheso ka potlako.

(3) Botšepehi bo tiileng ba Khase: Sebopeho se ke keng sa qoelisoa se thibela ho kenella ha khase, ho bohlokoa bakeng sa lits'ebetso tsa vacuum kapa sepakapaka se laoloang.

3. Ho nolofatsa li-tubes tse sireletsang tsa Next-Generation Technologies SiC ho notlolla mahlale a macha libakeng tse ntseng li hlaha:

(1) Moruo oa Hydrogen: Sebeletsa e le li-sheaths tse tšoarellang bakeng sa li-sensor tlhahiso ea haedrojene, polokelo le lisele tsa mafura, ho hanela ho hlakoloa le ho pepeseha ha khatello e phahameng ea H₂.

(2) Tlhahiso ea Semiconductor: Sireletsa lisensara tsa optical le thermal ho CVD (Chemical Vapor Deposition) reactor ho tsoa ho li-precursors tse senyang joalo ka silane kapa ammonia.

(3) Patlisiso ea Sepakapaka: Tšireletso ea lisebelisoa ka har'a lienjine tsa rokete le lipolanete tse tsoang ho likhahla tse feteletseng tsa mocheso le mahlaseli a bokahohle.

4. Theko-e Atlehang ka Bophelo bo Bolelele

Le ha li-tubes tsa SiC li na le litšenyehelo tse holimo pele, melemo ea bophelo ba bona e hlalosa boleng bocha:

(1) Nako e fokotsehileng ea ho phomola: Mekhoa e meng ea tšepe ea Outlast kapa quartz ka 4-6x ka litlhophiso tsa abrasive kapa acidic, ho fokotsa tlhokomelo e sa reroang.

(2) Litlhoko tsa ho Koaheloa ha Zero: Ho fapana le litšepe tse hlokang lirafshoa tse sirelletsang, thepa ea tlhaho ea SiC e tlosa litšenyehelo tse iphetang tsa kalafo ea holim'a metsi.

(3) Reusability: Pholoha lipotoloho tse ngata tsa ts'ebetso lits'ebetsong tse kang ho lahla tšepe kapa ho etsa khalase ntle le ho senyeha.

5. Customization bakeng sa Litlhoko tse Khethehileng

Li-tubes tse sireletsang tsa SiC li ikamahanya le liphephetso tsa niche ka boenjiniere bo hlophisitsoeng:

(1) Meralo ea Hybrid: Kopanya le litšepe kapa lirafshoa bakeng sa likopano tse nang le mesebetsi e mengata (mohlala, lihokelo tse khoeleng, li-flange).

(2) Liphetoho tsa Moaho: Bokahare bo bentšitsoeng bakeng sa lisebelisoa tsa optical kapa bokantle bo entsoeng ka masela ho ntlafatsa phallo ea mocheso.

(3) Boholo bo Fetohang: E entsoe ho tloha ho limilimithara (lab-scale reactors) ho isa ho limithara (li-kilns tsa indasteri).

6. Ho lumellana ho tsitsitseng

Li-tubes tsa SiC li tšehetsa mekhoa e metle ea indasteri:

(1) Poloko ea Matla: Tšebeliso e phahameng ea mocheso e fokotsa tšebeliso ea mafura a sebōpi ho fihla ho 20% ha e bapisoa le lithebe tsa tšepe.

(2) Phokotso ea Litšila: Bophelo ba nako e telele ba ts'ebeletso bo fokotsa litšila tsa thepa ho tsoa khafetsa.

(3) Ho Fokotsa Chefo: Felisa tlhoko ea liphahlo tse kotsi (mohlala, li-alloys tse thehiloeng ho nickel) libakeng tse senyang.

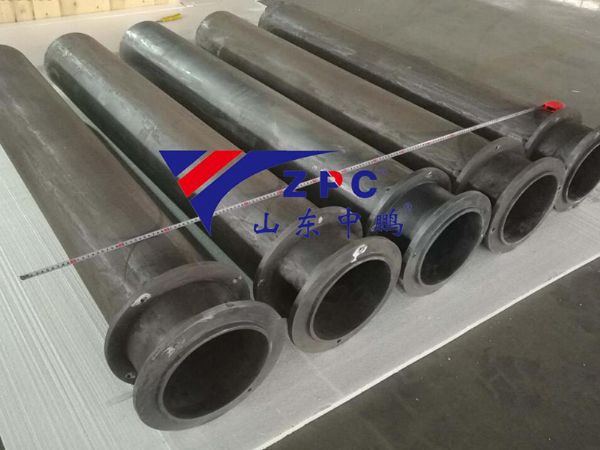

Shandong Zhongpeng Special Ceramics Co., Ltd ke e 'ngoe ea litharollo tse ncha tsa silicon carbide ceramic China. SiC tekheniki ea ceramic: Ho thatafala ha Moh ke 9 (Bothata ba Moh e Ncha ke 13), e nang le khanyetso e babatsehang ea khoholeho ea mobu le ho bola, ho senya ho hoholo - ho hanyetsa le ho thibela oxidation. Bophelo ba tšebeletso ea sehlahisoa sa SiC bo bolelele ba makhetlo a 4 ho isa ho a 5 ho feta 92% ea lisebelisoa tsa alumina. MOR ea RBSiC ke 5 ho makhetlo a 7 ea SNBSC, e ka sebelisoa bakeng sa libopeho tse rarahaneng haholoanyane. Ts'ebetso ea quotation e potlakile, thomello e joalo ka ha e ts'episitsoe 'me boleng ha bo na letho. Re lula re phehella ho phephetsa lipakane tsa rona le ho khutlisetsa lipelo tsa rona sechabeng.