E etselitsoe ho mamella mathata a ts'ebetso a feteletseng,lithaele tsa silicon carbidee se e le lisebelisoa tsa tekanyetso bakeng sa liindasteri tse hlokang tšireletso e sa sekisetseng. Microstructure ea eona e ikhethang e fana ka ts'ebetso e ikhethang ho: - Libaka tse matla tsa abrasion tse sebetsanang le likaroloana tse mahoashe (~ 5mm)

- Litsamaiso tse nang le phello e phahameng le ho tlosa metsi

- Lipalangoang tsa mecha ea litaba tse senyang ka har'a likorale le limela tsa lik'hemik'hale

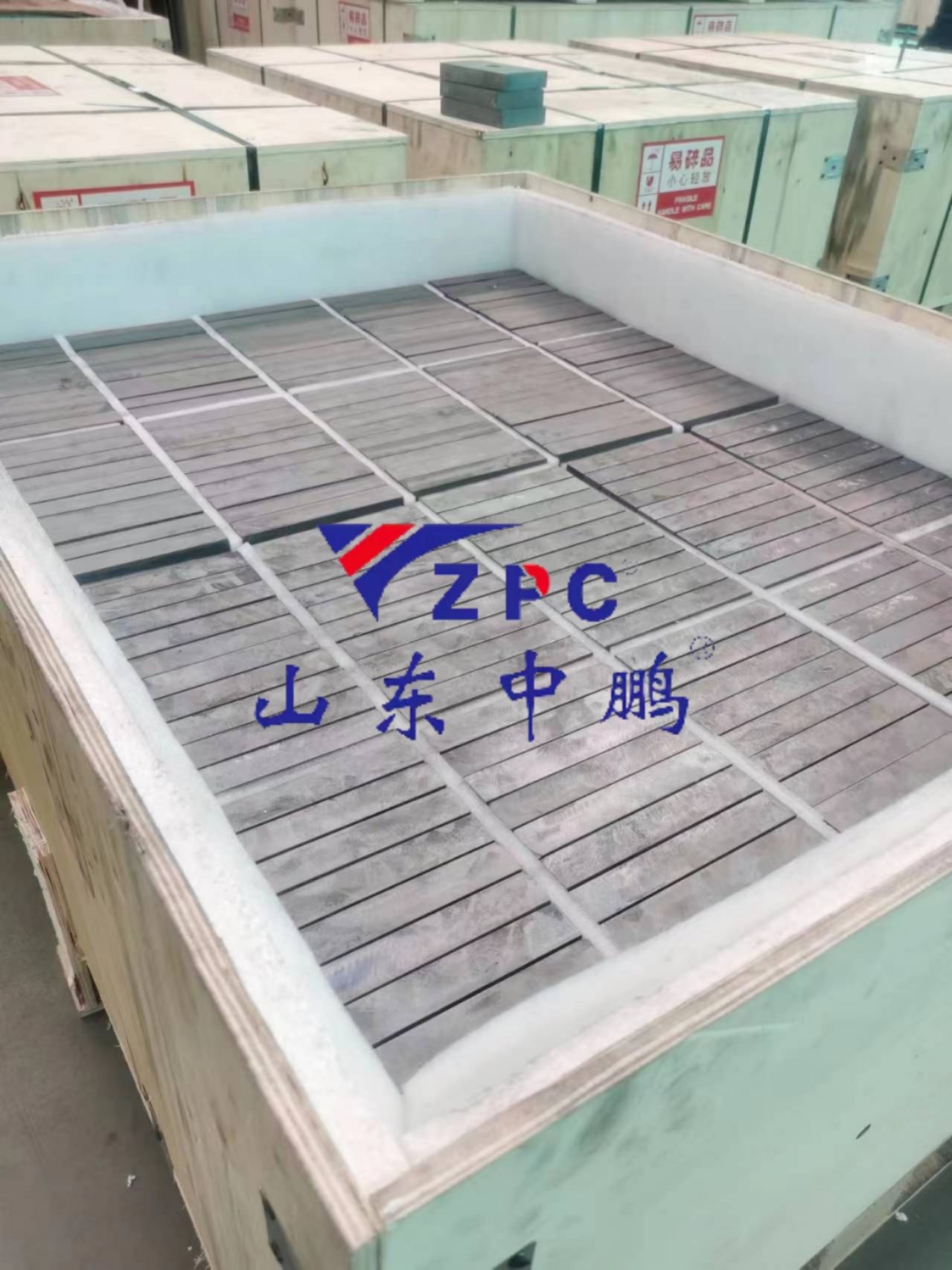

Ho tloha ho li-conveyors tsa tšepe tsa leloala ho isa lifahlehong tse tiisitsoeng tsa mochini tlhahisong ea thepa e tala,lithaele tsa silicon carbidelikaroloana li sebetsa joalo ka lihlomo tsa boenjiniere - li sireletsa hantle lintlha tsa bohlokoa tsa ho roala ha li ntse li boloka botsitso tlas'a khatello e tsoelang pele. Ha tlhokahalo e ntse e eketseha ea lithaele tsa silicon carbide, lithapo le liphaephe ho pholletsa le liketane tsa ho lokisa liminerale, bareki ba nang le temoho ba lokela ho beha matšoao ana pele:

1. Moralo o Tsamaiswang ke Lefa

Motsoako oa rona oa Sejeremane o etsa liteko tse ngata tsa khoholeho ea mobu, ho fihlela litefiso tsa tahlehelo ea thepa e ka tlase ho 0.86㎝³ - e leng bopaki ba botšepehi ba matrix a silicon carbide tiles.

2. Protocol ea netefatso ea boima

Lithaele tsa Silicon carbide li etsa 'mapa oa khatello ea kelello ea triaxial, e bonts'ang boima ba Mohs bo bocha ba 14.55±4.5 ka ≤2% MOR phapang ho pholletsa le lihlopha tsa tlhahiso.

3. Taolo ea ho nepahala ha Density Precision

Substanding sintering e baka bofokoli ba sebopeho. Ts'ebetso ea rona ea lithaele tsa silicon carbide e boloka letsoalo la 3.03±0.05g/㎝³ ka maqhama a karabelo a thusang khatello, ho tlosa likheo tse ka tlas'a lefatše.

4. Phethahatso ea Geometri

▸ Ho bata ha bokaholimo ho netefalitsoeng ka laser (<0.02mm/m²)

▸ Ho tsitsa ha radius (0.5±0.1mm)

▸ Setifikeiti sa 100% sa crack/pore-free

E fetileng: Silicon carbide e khanyang tube E 'ngoe: Silicon carbide e khanyang tube