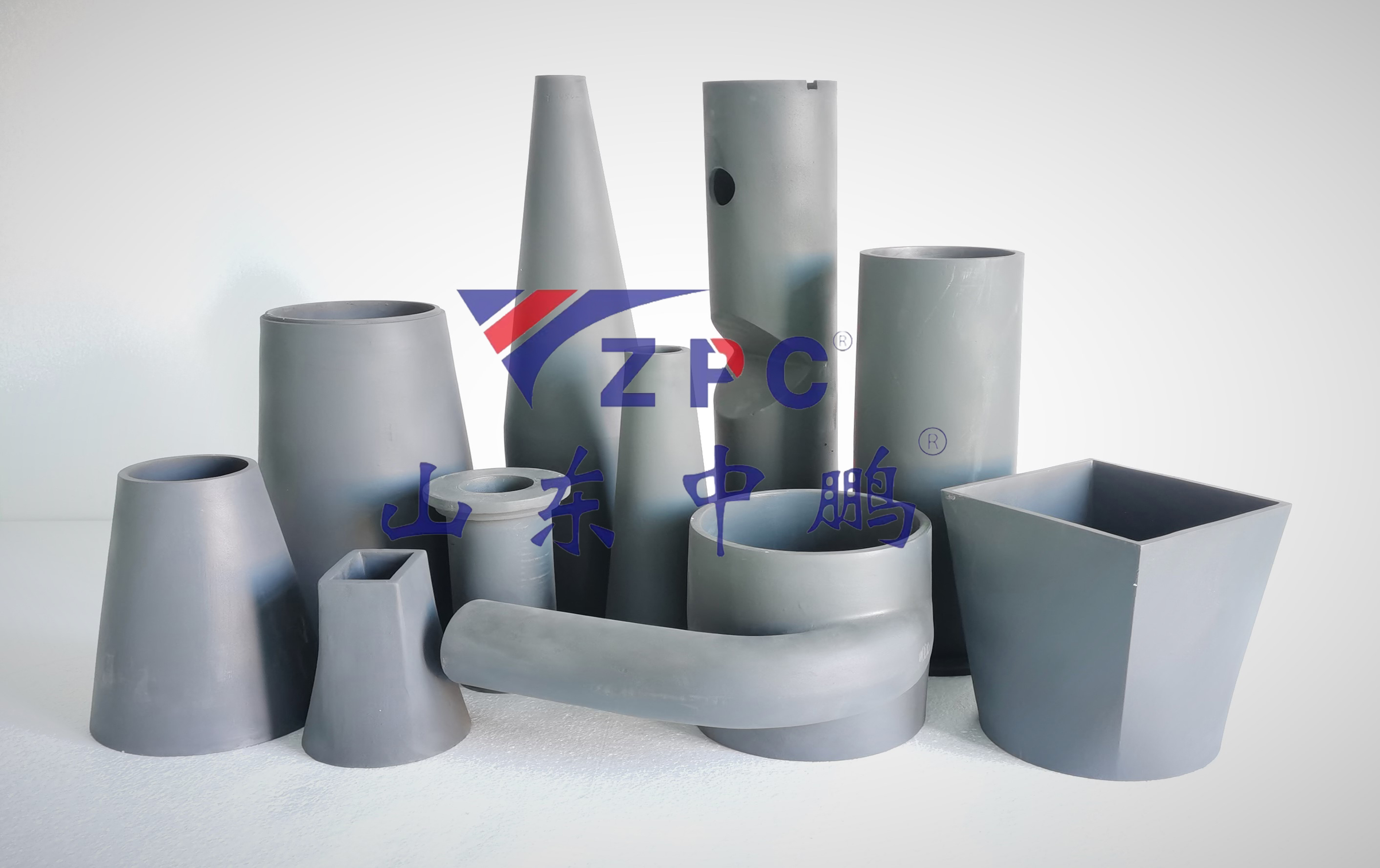

Lisebelisoa tsa silicon carbide ceramic

Lesela le hananang le silicon carbide

Likarolo tsa Moqapi oa Silicon Carbide (SiC) Liner-Resistant Liner:

(1) Moralo o Nolofalitsoeng oa Tsela ea Phallo

Khoutu e boreleli, e hlophisitsoeng hantle ho tloha ho seketsoana ho ea ho kantle e fokotsa khanyetso ea phallo, e etsa hore li-liner tsa SiC li ikamahanye le lits'ebetso tse fapaneng tsa indasteri.

(2) Atomization e tsoetseng pele

MechanismLiquids e entsoe ka athomo hore e be marotholi a matle ka ho thulana ka matla 'me ho ntse ho fokotseha butle-butle libaka tsa helical tsa SiC liner, ho netefatsa hore ho ajoa ka mokhoa o ts'oanang.

(3) Sebopeho sa Compact, Se sa Tletseng

Mocha oa phallo o otlolohileng, o se nang letho o felisa litšitiso tse ka hare, o eketsa phallo ea mokelikeli ka har'a liphaephe tse koaletsoeng ha o ntse o thibela ho thibela.

(4) Mefuta e 'meli ea Spray bakeng sa Bokhoni bo Ntlafetseng

E ts'ehetsa lipaterone tsa solid-cone le hollow-cone spray, e fana ka li-angles tse koahelang bophara le ts'ebetso ea anti-clogging bakeng sa ts'ebetso e sebetsang hantle.

Melemo ea mantlha ha e bapisoa le lisebelisoa tse ling:

(1) Ho se Bapisoe ho Wear Resistance

Ho thatafala: Li-liner tsa SiC li fumana boima ba Mohs ba 9.5 (khal. 8.0 bakeng sa lirafshoa tsa alumina, 6.0 bakeng sa tšepe e phahameng ea chromium), e li nolofalletsang ho mamella ho senyeha ho feteletseng ha li-slurries tsa merafo, molora oa mashala le phofo ea tšepe.

Nako e telele: Bophelo ba ts'ebeletso bo feta 5-10× lisebelisoa tsa setso (mohlala, rabara kapa lithapo tsa polyurethane) lits'ebetsong tse nang le tšusumetso e matla joalo ka liloala tsa bolo kapa lipompo tsa slurry.

(2) Ho senyehe ha Kotsi le Lik'hemik'hale

Khanyetso ea Asiti/Alkali: E hanana le asiti e ngata ea sulfuric (98%), sodium hydroxide (50%), le matsoai a qhibilihisitsoeng (mohlala, NaCl-KCl ho 800°C), athe litšepe li senyeha ka potlako le li-polymers li senyeha.

Tšilafalo ea Zero: Sebaka se sa sebetseng se tiisa bohloeki ho semiconductor kapa tlhahiso ea betri ea lithium, ho fapana le lithapo tsa tšepe tse tloaetseng ho tsoa ion leaching.

(3) Botsitso bo Feteletseng ba Mocheso

Thermal Resilience: E sebetsa ka mokhoa o tsoelang pele ho 1,600 ° C (ha e bapisoa le moeli oa alumina oa 1,200 ° C) ka katoloso e nyane ea mocheso (CTE: 4.0×10⁻⁶/℃), e thibela ho phatloha ha libopi kapa libōpi tse qhibilihisang.

Thermal Shock Resistance: E boloka botšepehi ba sebopeho tlas'a ho fetoha ha mocheso ka potlako (mohlala, ho tima ho tloha ho 1,000 ° C ho ea mocheso oa kamore), ho fapana le lirafshoa tse brittle.

(4)Katleho ea Matla le Boqapi bo Bobebe

Low Friction: Sebaka sa SiC se pholisitsoeng (Ra <0.1 μm) se fokotsa khanyetso ea mokelikeli ka 30-50% khahlano le lithapo tsa tšepe tse thata, ho fokotsa litšenyehelo tsa matla a ho pompa.

Ho boloka Boima ba 'Mele: Boima ba 3.1 g/cm³ (ha e bapisoa le 7.8 g/cm³ ea tšepe) e nolofatsa ho kengoa le ho tšehetsa lisebelisoa tse bobebe sebakeng sa sefofane kapa li-mobile processing units.

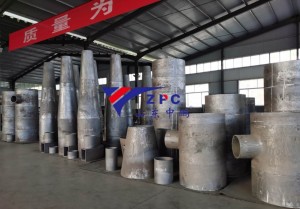

Shandong Zhongpeng Special Ceramics Co., Ltd ke e 'ngoe ea litharollo tse ncha tsa silicon carbide ceramic China. SiC tekheniki ea ceramic: Ho thatafala ha Moh ke 9 (Bothata ba Moh e Ncha ke 13), e nang le khanyetso e babatsehang ea khoholeho ea mobu le ho bola, ho senya ho hoholo - ho hanyetsa le ho thibela oxidation. Bophelo ba tšebeletso ea sehlahisoa sa SiC bo bolelele ba makhetlo a 4 ho isa ho a 5 ho feta 92% ea lisebelisoa tsa alumina. MOR ea RBSiC ke 5 ho makhetlo a 7 ea SNBSC, e ka sebelisoa bakeng sa libopeho tse rarahaneng haholoanyane. Ts'ebetso ea quotation e potlakile, thomello e joalo ka ha e ts'episitsoe 'me boleng ha bo na letho. Re lula re phehella ho phephetsa lipakane tsa rona le ho khutlisetsa lipelo tsa rona sechabeng.