Ho tloha liphaepheng tsa lipalangoang ho ea likoloing tse ncha tsa matla, ho tloha ho li-kilns tsa mocheso o phahameng ho isa ho lisathelaete tsa sefofane, ntho e tsejoang e le "daemane ea indasteri" e ntse e ngola ka khutso meeli ea tlhahiso ea morao-rao.Li-ceramics tsa silicon carbide, thepa e matla haholo e nang le boima ba bobeli feela ho daemane ea tlhaho, e baka phetoho e khutsitseng likarolong tse sa tšoaneng tse kang indasteri ea morao-rao, li-semiconductors, sefofane, le matla a macha ka lebaka la ho hanyetsa mocheso o phahameng, ho hanyetsa mahlaseli a matla, le conductivity e babatsehang ea mocheso.

Ha 'masapo a thata' a kopana le tlhahiso e nepahetseng

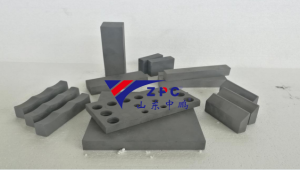

Haeba li-ceramics tsa setso li le putsoa le porcelain e tšoeu ka bonono le mesebetsi ea matsoho, li-ceramics tsa silicon carbide li tšoana le lioache tsa Switzerland ka lisebelisoa tse nepahetseng. Boima ba eona ke ka makhetlo a 3-5 ho feta li-ceramics tse tloaelehileng, 'me bothata bona bo haufi le litaemane tsa tlhaho bo etsa hore mokhoa oa ho sebetsa o tšoana le ho betla lipoleiti tsa tšepe - lisebelisoa tse tloaelehileng tsa ho itšeha li senyeha ka lebelo le makatsang nakong ea ho itšeha. Ntho e qhekellang le ho feta ke hore mofuta o "thata" oa silicon carbide o etsa hore e sekamele ho qhekella leha e le phoso e nyane nakong ea ts'ebetso, haholoholo bakeng sa likarolo tse nang le mabota a masesaane tse hlokang tlhokomeliso e ts'oanang le mesebetsi ea bonono ea kristale.

Empa tlhoko ea indasteri ea sejoale-joale e nts'etsapele katleho ea theknoloji. Baenjiniere ba fumane hore senotlolo sa ho rarolla bothata bona ke ho kopanya ho thatafala le ho feto-fetoha ha maemo: ho boloka thepa ea ka hare ea thepa ha u ntse u sebelisa taolo e nepahetseng nakong ea ts'ebetso. Joalo ka baapehi ba kaholimo ba tseba mocheso, mekhoa ea sejoale-joale ea ho lokisa butle-butle e thapisa thepa ena e manganga ka ho laola mocheso hantle, khatello le maqhubu a ho thothomela.

Linotlolo tse tharo tsa ho notlolla litaemane tsa indasteri

1. Mocheso o hatellang ho bopa

Ena ke e 'ngoe ea mekhoa e atileng haholo ea ho lokisa lirafshoa tsa silicon carbide. Mokhoa ona o beha silicon carbide phofo kapa phofo e tsoakiloeng ka har'a hlobo e hatellang e chesang ebe e e etsa sebopeho tlas'a mocheso o phahameng le khatello. E na le ts'ebetso e phahameng ea tlhahiso le ho nepahala ha sebopeho, 'me e loketse ho hlahisa lihlahisoa tse kholo tsa silicon carbide ceramic tse kang lisebelisoa tsa ho itšeha, lipoleiti tsa aluminium tse chesang tse chesang, joalo-joalo.

2. Ho bopa ha grouting

Ona ke mokhoa o theko e tlase le o potlakileng oa ho etsa lihlahisoa tsa silicon carbide ceramic. Mokhoa ona o kopanya phofo ea silicon carbide le li-additives tse ling, o li kenya metsing ho etsa slurry, ebe o e kenya ka har'a hlobo e bopehileng. Ka mor'a moo, e sebetsanoa le ho thehoa ka ho omisa le ho sintering ea mocheso o phahameng, ka potoloho e khutšoanyane ea ts'ebetso le theko e tlaase. E loketse bakeng sa ho lokisetsa likarolo tse matla, tse nang le matla a mangata le likarolo tse jereng thepa.

3. Metallurgy ea phofo

Metallurgy ea phofo ke mokhoa oa ho kopanya le ho etsa phofo ea silicon carbide ka tekanyo e itseng, ebe o e sila ka mocheso o phahameng le khatello e phahameng. Mokhoa ona o na le mokhoa o bonolo oa tlhahiso, libopeho tse fapaneng tsa lihlahisoa, le ho nepahala ho phahameng ho sebetsa, ho etsa hore e loketse ho hlahisa lihlahisoa tsa ceramic tse nepahetseng, tse matla le tse sa tsitsang.

Ho tloha lisampoleng tsa laboratori ho ea ho tlhahiso ea bongata mocheng oa tlhahiso, katleho ea ts'ebetso ea li-ceramics tsa silicon carbide e tiisa 'nete: ha ho na thepa e ke keng ea sebetsoa, ke theknoloji feela e e-s'o robehe. Ka kholo ea mahlale a macha a kang laser processing le microwave sintering, thepa ena e kileng ea nyarosa e nchafatsa lifekthering tse bohlale, e kenya matla a mantlha ho "machaena a bohlale a tlhahiso".

Leoatleng le leholo la lipatlisiso tsa sebaka le leqhubu le letala la matla a hloekileng, li-ceramics tsa silicon carbide li ngola tšōmo ea indasteri ea nako ena ka botle ba bona bo ikhethang. Khohlano ena lipakeng tsa thatafalo le bohlale e kanna ea ba mohlala oa ka ho sa feleng oa batho ba tlolang meeli ea thekenoloji.

Nako ea poso: Apr-09-2025