Silicon carbide (SiC) e bonts'a moaparo o ikhethang le ho hanyetsa kutu ka lebaka la thepa ea eona e ikhethang ea 'mele le ea lik'hemik'hale.

Mabapi le ho hanyetsa ho roala, boima ba Mohs ba silicon carbide bo ka fihla ho 9.5, ea bobeli feela ho daemane le boron nitride. Ho hanyetsa ha eona ho lekana le makhetlo a 266 a tšepe ea manganese le makhetlo a 1741 a tšepe e phahameng ea chromium.

Mabapi le ho hanyetsa kutu, silicon carbide e na le botsitso bo phahameng haholo ba lik'hemik'hale mme e bonts'a khanyetso e ntle ho li-acid tse matla, alkalis le tharollo ea letsoai. Ho sa le joalo, silicon carbide e boetse e na le khanyetso e phahameng ea kutu ho litšepe tse qhibilihisitsoeng joalo ka aluminium le zinki, 'me e sebelisoa hangata ho li-crucibles le hlobo indastering ea metallurgic.

Hajoale, silicon carbide e kopantsoeng le sebopeho sa superhard le lik'hemik'hale tsa eona tsa lik'hemik'hale li 'nile tsa sebelisoa haholo liindastering tse kang merafo, tšepe le lik'hemik'hale, ho fetoha khetho e nepahetseng ea thepa tlas'a maemo a feteletseng a ho sebetsa.

| thepa | apara khanyetso | khanyetso ea kutu | tshebetso e phahameng ya mocheso | Moruo (nako e telele) |

| Silicon carbide | E phahameng haholo | E matla haholo | E ntle haholo (((1600℃) | Phahameng |

| Li-ceramics tsa aluminium | Phahameng | E matla | Karolelano (((1200℃) | Mahareng |

| Motsoako oa tšepe | Mahareng | E fokola (e hloka ho roala) | E fokola (e tloaelehileng ho oxidation) | E fokola |

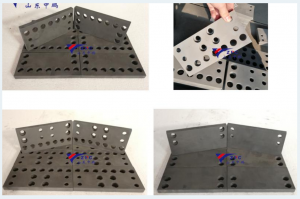

Thibelo e thibelang ho roala silicon carbideke karolo ea bohlokoa ho lihlahisoa tsa silicon carbide.Thepa ea silicon carbide e thibelang ho roala le ho senya e etsa hore e sebelisoe haholo lisebelisoa tsa ho sila tse kang li-crushers tsa morafo le li-ball Mills, ho fokotsa khafetsa lisebelisoa tse nkeloang sebaka ka lebaka la ho roala le ho fokotsa litšenyehelo tsa tlhokomelo ea mochine.

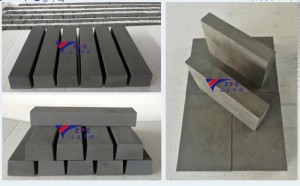

Se latelang ke papiso lipakeng tsa li-block tsa silicon carbide le li-blocks tse ling tsa setso tse sa keneng:

| Ho thatafala le ho Rua Khanyetso | Thibelo e thibelang ho roala silicon carbide | Lisebelisoa tsa setso |

| Ho thatafala le ho Rua Khanyetso | Mohs hardness 9.5, ho hanyetsa ho matla haholo (bophelo bo eketsehile ka makhetlo a 5-10) | tšepe e phahameng ea chromium e na le boima bo tlase (HRC 60 ~ 65), 'me lirafshoa tsa alumina li na le monyetla oa ho robeha habonolo. |

| Khanyetso ea kutu | E hanana le li-acid tse matla le alkalis | Litšepe li na le tšekamelo ea ho bola, ha alumina e na le karolelano ea ho hanyetsa asiti |

| Botsitso bo phahameng ba mocheso | Ho hanyetsa mocheso oa 1600 ℃, ha ho na oxidizing ka mocheso o phahameng | Metal e na le tšekamelo ea ho senyeha ha mocheso o phahameng, ha alumina e na le mocheso o hanyetsang oa 1200 ℃ feela. |

| Thermal conductivity | 120 W / m · K, ho senya mocheso ka potlako, ho hanyetsa mocheso oa mocheso | Metal e na le conductivity e ntle ea mocheso empa e na le oxidation, ha lirafshoa tse tloaelehileng li na le mocheso o fokolang oa mocheso. |

| Moruo | Nako e telele ea bophelo le litšenyehelo tse tlase ka kakaretso | Litšepe li hloka ho nkeloa sebaka khafetsa, li-ceramics lia senyeha, 'me litšenyehelo tsa nako e telele li phahame |

Nako ea poso: Mar-18-2025