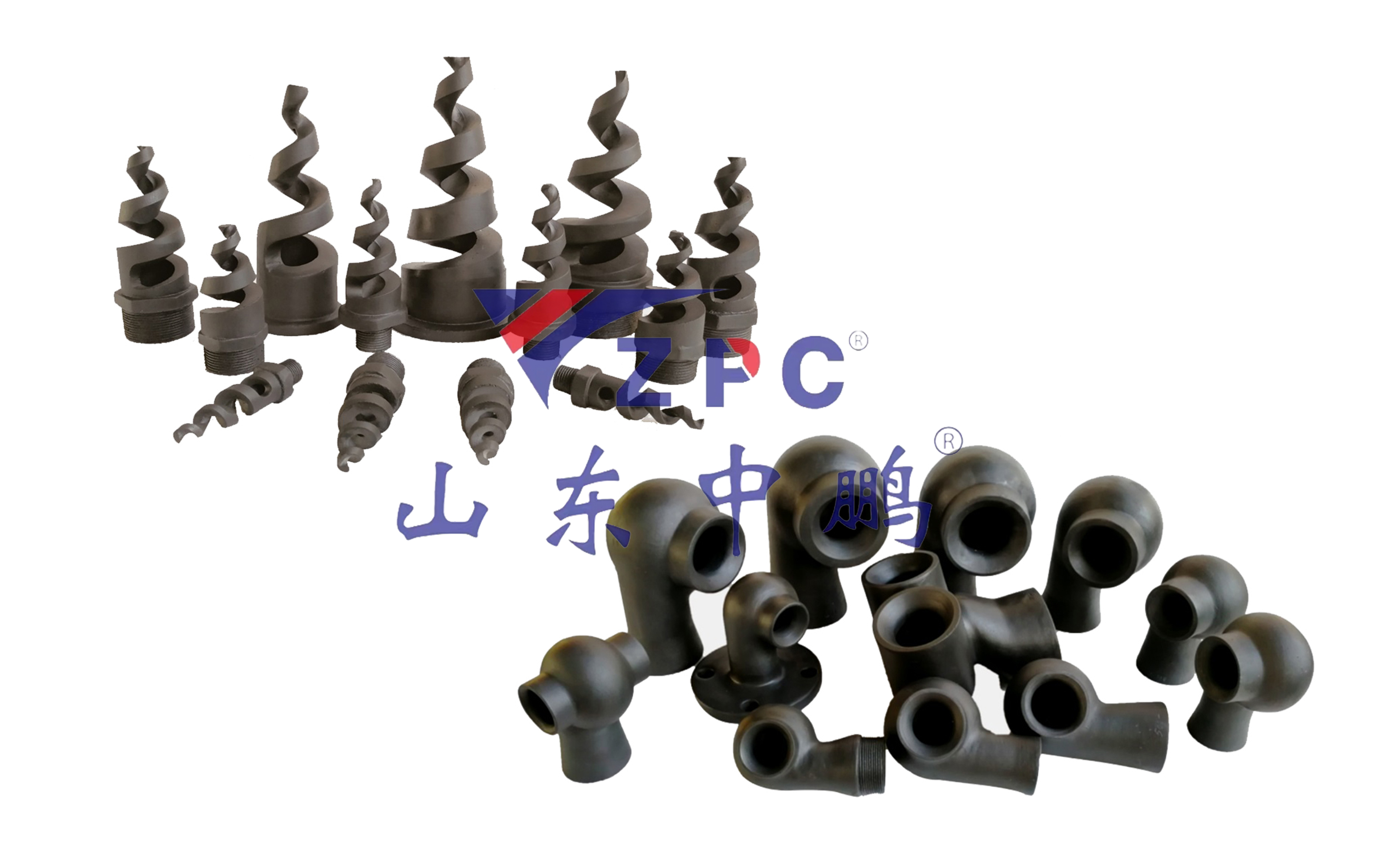

E le karolo ea mantlha ea lits'ebetso tsa sejoale-joale tsa tlhoekiso ea khase ea flue,silicon carbide FGD Nozzlese bapala karolo ea bohlokoa mafapheng a indasteri joalo ka matla a mocheso le metallurgy. Nozzle ena ea silicon carbide ceramic e atlehile ho rarolla bothata ba botekgeniki ba li-nozzles tsa tšepe tsa setso tlas'a kutu e matla le maemo a holimo a ho apara ka moralo o mocha oa meralo le katleho ea thepa, e ntlafatsang haholo ts'ebetso ea desulfurization.

1, Thepa ea thepa e rala motheo oa ts'ebetso

The Mohs hardness ofli-ceramics tsa silicon carbidee fihla ho 9.2, e leng ea bobeli ka mor'a taemane, 'me ho robeha ha eona ho imenne ka makhetlo a mararo ho feta a ceramic ceramics. Sebopeho sena sa covalent sa kristale se fana ka thepa e nang le khanyetso e ntle ea abrasion, 'me tlas'a tšusumetso ea seretse se phahameng se nang le likristale tsa gypsum (sekhahla sa phallo ho fihla ho 12m / s), sekhahla sa ho roala holimo ke 1/20 feela ea li-nozzles tsa tšepe. Sebakeng se fapanyetsanang sa acid-base se nang le pH ea 4-10, sekhahla sa ho hanyetsa ha silicon carbide se ka tlase ho 0.01mm / selemo, se molemo haholo ho feta 0.5mm / selemo sa 316L tšepe e sa hloekang.

Coefficient ea ho atolosa mocheso oa thepa (4.0 × 10 ⁻⁶/℃) e haufi le ea tšepe, 'me e ntse e ka boloka botsitso ba sebopeho tlas'a phapang ea mocheso oa 150 ℃. Silicon carbide ceramics e lokisitsoeng ke reaction sintering process e na le letsoalo la ho feta 98% le porosity e ka tlase ho 0.5%, e thibelang tšenyo ea sebopeho e bakiloeng ke ho kenella ha mahareng.

2. Mokhoa o nepahetseng oa atomization le taolo ea tšimo ea phallo

Thesilicon carbide spiral nozzlee eketsa haholo lebelo la seretse, 'me ka lesoba le nepahetseng la ho tsoa, e pshatla lejoe la mokoetla hore e be marotholi a manyane le a tšoanang. Sekhahla sa sekoaelo sa tšimo ea sekoaelo se entsoeng ke sebopeho sena se seholo haholo, 'me nako ea ho lula ea marotholi a tora e atolosoa ho fihlela metsotsoana e 2-3, 40% e phahame ho feta ea li-nozzles tsa setso.

3. Ho tsamaisana le sistimi le ntlafatso ea boenjiniere

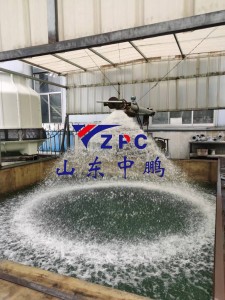

Ka tora e tloaelehileng ea ho fafatsa,silicon carbide FGD nozzlesli hlophisitsoeng ka mokhoa oa chessboard li sebelisoa, ka sebaka sa 1.2-1.5 makhetlo a bophara ba cone ea spray, ho etsa likarolo tse 3-5 tsa ho koahela. Tokisetso ena e etsa bonnete ba hore tšireletso ea likaroloana tsa tora ea desulfurization e feta 200%, ho netefatsa hore ho na le kamano e lekaneng pakeng tsa khase ea flue le slurry. Ka sekhahla sa phallo ea tora e se nang letho ea 3-5 m / s, tahlehelo ea khatello ea sistimi e laoloa ka har'a sebaka sa 800-1200 Pa.

Lintlha tsa ts'ebetso li bonts'a hore ts'ebetso ea desulfurization ea sistimi ea FGD e sebelisang li-nozzle tsa silicon carbide e lula e tsitsitse ho feta 97.5%, 'me mongobo oa lihlahisoa tsa gypsum o fokotsehile ho ba ka tlase ho 10%. Potoloho ea tokiso ea lisebelisoa e ekelitsoe ho tloha likhoeling tse 3 bakeng sa li-nozzles tsa tšepe ho ea ho lilemo tse 3, 'me litšenyehelo tsa ho nchafatsa likarolo tse ling li theohile ka 70%.

Tšebeliso ea senaFGD nozzlee tšoaea ho tlola ho tloha lisebelisoa tse ngata ho isa ho tse nepahetseng tsa ts'ireletso ea tikoloho. Ka kholo ea theknoloji ea 3D ea khatiso ea ceramic, moralo oa topology optimization oa sebopeho sa mocha oa phallo o ka phethahala nakong e tlang, o ka ntlafatsang ts'ebetso ea atomization ka 15-20% le ho khothaletsa theknoloji ea "ultra-low emission" ho kena mothating o mocha oa nts'etsopele.

Nako ea poso: Mar-24-2025