Reaction-sinteredsilicon carbide ceramic, eo hape e tsejoang e le RS-SiC, ke thepa e tsoetseng pele ea ceramic e hohetseng tlhokomelo e atileng ka lebaka la ts'ebetso ea eona e ntle haholo le mefuta e mengata ea lits'ebetso. Li-ceramics tsena li hlahisoa ka mokhoa o bitsoang reactive sintering, e kenyelletsang carbon le silicon e sebetsanang le mocheso o phahameng ho etsa silicon carbide. Thepa e hlahisoang e na le thepa e babatsehang ea mechine, ea mocheso le ea lik'hemik'hale, e etsang hore e tšoanelehe bakeng sa mefuta e sa tšoaneng ea lisebelisoa tsa indasteri.

O mong oa melemo ea mantlha ea karabelo-sintered silicon carbide ceramics ke ho thatafala ha eona ho ikhethang le ho hanyetsa ho roala. Mehaho ena e etsa hore e be e loketseng bakeng sa ho sebelisoa libakeng tse boima tse kang merafo, moo lisebelisoa li ka senyehang le ho senyeha. Likarolo tsa RS-SiC tse kang li-liner tse sa sebetseng, li-nozzles le li-impellers li sebelisoa haholo mesebetsing ea merafo ho ntlafatsa ts'ebetso le ts'ebetso ea lisebelisoa tse pepesehetseng thepa le maemo a thata. Khanyetso e phahameng ea ho roala ha li-ceramics tsa RS-SiC e thusa ho fokotsa litšenyehelo tsa nako le tlhokomelo, e leng se etsang hore e be khetho ea pele bakeng sa lits'ebetso tsa merafo.

Ho phaella ho merafo, karabelo-sinteredli-ceramics tsa silicon carbideli sebelisoa haholo indastering ea matla. Ts'ebetso e ntle ea mocheso oa RS-SiC le botsitso ba mocheso o phahameng li etsa hore e be sesebelisoa se loketseng likarolo tsa phepelo ea matla le lits'ebetso tsa phepelo. Li-ceramics tsena li sebelisoa lits'ebetsong tse kang lisebelisoa tse futhumatsang mocheso o phahameng, li-tubes tsa ts'ireletso ea thermocouple, le lisebelisoa tsa insulate bakeng sa ho kenya motlakase. RS-SiC e khona ho mamella mocheso o feteletseng le ho tsieleha ha mocheso, e leng se etsang hore e be khetho e ka tšeptjoang bakeng sa likarolo tsa bohlokoa tsa limela tsa motlakase le tsamaiso ea motlakase.

Ho feta moo, ho se sebetse ha lik'hemik'hale tsa karabelo-sintered silicon carbide ceramics ho etsa hore e loketse ho sebelisoa libakeng tse senyang. Li hanyetsana le tlhaselo ea lik'hemik'hale le oxidation 'me li sebelisoa indastering ea tlhahiso ea lik'hemik'hale, metallurgical le semiconductor. Likarolo tsa RS-SiC li sebelisoa mekhoeng e amanang le lik'hemik'hale tse senyang, litšepe tse qhibilihisitsoeng le likhase tse nang le mocheso o phahameng oa mocheso moo thepa e tloaelehileng e ka senyang kapa ea hlōleha. Ho hanyetsa kutu le botsitso ba lirafshoa tsa RS-SiC li thusa ho eketsa nako e telele ea lisebelisoa le ho tšepahala libakeng tsena tse thata.

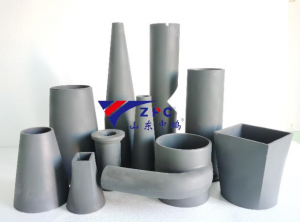

Joaloka moetsi e moholo ka ho fetisisa oa likarolo tse khethehileng tsa silicon carbide ceramic tse nang le sebōpeho se khethehileng Chaena, k'hamphani ea rona e ikemiselitse ho fana ka likarolo tse entsoeng ka boleng bo phahameng ba RS-SiC ho finyella litlhoko tse khethehileng tsa liindasteri tse fapaneng. Re fana ka mefuta e fapaneng ea likarolo tsa ceramic tse entsoeng ka nepo, ho kenyeletsoa lijeometri tse rarahaneng le meralo e rarahaneng, ho fihlela litlhoko tse ikhethang tsa bareki ba rona. Tsebo ea rona ea theknoloji e sebetsang ea sintering e re lumella ho hlahisa libopeho tse rarahaneng tse nang le mamello e thata, ho netefatsa ts'ebetso e nepahetseng le bophelo ba ts'ebeletso ea likarolo tsa ceramic lits'ebetsong tse fapaneng.

The versatility of reaction-sinteredli-ceramics tsa silicon carbidee fetela ka nģ'ane ho litšobotsi tsa eona tsa mochine le tsa lik'hemik'hale. Li-ceramics tsena li boetse li bonts'a ts'ebetso e ntle ea motlakase, katoloso e tlase ea mocheso le ho satalla ho hoholo, ho etsa hore li tšoanelehe ho sebelisoa lits'ebetsong tse tsoetseng pele tsa boenjiniere. Bokhoni ba bona ba ho boloka botsitso bo boholo mochesong o phahameng le tikolohong e thata e eketsa boipiletso ba bona indastering ea lifofane, tsa likoloi le tsa ts'ireletso. Likarolo tsa RS-SiC li sebelisoa mekhoeng ea ho tsamaisa sefofane, litsamaiso tsa braking tsa likoloi le lisebelisoa tsa lihlomo, moo thepa ea bona e phahameng e thusang ho ntlafatsa ts'ebetso le ts'epo.

Ka kakaretso, lirafshoa tsa silicon carbide ceramics li fana ka motsoako o qobellang oa thepa e etsang hore e be ea bohlokoa haholo lits'ebetsong tse fapaneng tsa indasteri. Ho thatafala ha eona ho ikhethang, ho hanyetsa ho roala, ho tsamaisa mocheso le ho se sebetse ha lik'hemik'hale ho etsa hore e be khetho ea pele bakeng sa tikoloho e hlokang merafo, tlhahiso ea matla, ts'ebetso ea lik'hemik'hale le liindasteri tse ling. E le moetsi ea ka sehloohong oa customizedsilicon carbide ceramiclikarolo tse nang le sebopeho se ikhethileng, k'hamphani ea rona e ikemiselitse ho fana ka litharollo tse ncha tse phahamisang melemo e ikhethang ea RS-SiC ho fihlela litlhoko tse lulang li fetoha tsa bareki ba rona. Re tsepamisitse maikutlo holim'a boleng, ho nepahala le ho itloaetsa, 'me re ikemiselitse ho ntšetsa pele ts'ebeliso ea lik'hemik'hale tsa silicon carbide tse arabelang likarolong tse sa tšoaneng, ho kenya letsoho ho ntlafatsa ts'ebetso, katleho le botšepehi ba mekhoa ea bohlokoa ea indasteri.

Nako ea poso: Jul-30-2024