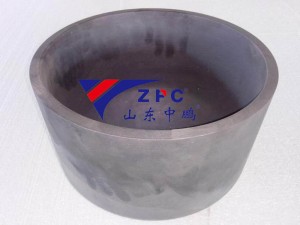

Reaction bonded silicon carbidelithupaemela katleho ea theknoloji ea refractory, e fanang ka ts'ebetso e ke keng ea lekanngoa libakeng tse chesang haholo. Lijana tsena tse tsoetseng pele tsa ceramic li fetohile tsa bohlokoa ho pholletsa le metallurgy, ho lahlela ka nepo, boenjiniere ba mechini, le indasteri ea ts'ebetso ea lik'hemik'hale, e fana ka ts'ebetso e phahameng moo lisebelisoa tsa setso li haellang.

Melemo ea Konokono ea Tekheniki

Li-crucible tsa RBSC li feta li-alumina tse tloaelehileng le li-graphite ka:

- Thermal conductivity e ikhethang (120–150 W/m·K ho 1000°C)

- Coefficient ea katoloso ea mocheso o tlase haholo (4.5×10⁻⁶/K)

- Ho hanyetsa mocheso oa mocheso ho mamella lipotoloho tse pholileng tse 50+ tse potlakileng (1600°C→ 25°C)

- Acid / alkali corrosion resistance (pH 0-14 e lumellana)

- Ho tsitsisa ha oxidation moeeng ho fihla ho 1650 ° C

Metallurgical Mastery

Ka tlhahiso ea tšepe ea alloy le ho qhibilihisa tšepe e seng ferrous (aluminium, koporo, zinki), li-crucible tsa RBSC li thusa:

- 20–30% lebelo la ho qhibiliha ha mocheso ka phetiso e ntlafalitsoeng ea mocheso

- 99.95% tlhokomelo ea bohloeki ba tšepe ka libaka tse sa sebetseng

- Fokotsa sebopeho sa slag ka ho fokotsa stratification ea mocheso

- Bophelo bo atolositsoeng ba ts'ebeletso (bolelele ba 3–5× ho feta lithupa tsa letsopa-graphite)

Precision Casting & Mechanical Applications

Thepa e ikhethang ea li-crucibles e tšehetsa litlhoko tse hlokahalang tsa indasteri:

- Botšepehi bo tsitsitseng ba sebopeho tlas'a khatello ea mochine ea 15-20 MPa

- Botsitso bo sa fetoheng ba sebopeho (± 0.1% phetoho ea molumo ho 1500°C)

- Ts'ebetso e se nang tšilafalo bakeng sa likarolo tsa boemo ba sefofane

- Ts'ebetso e tšepahalang lits'ebetsong tsa centrifugal casting

Lik'hemik'hale Tsa Bokhabane

Li-crucible tsa RBSC li sebetsana le mathata a bohlokoa ka har'a motsoako oa lik'hemik'hale:

- Sets'oants'o se bolokehileng sa letsoai le qhibilihisitsoeng (mohlala, NaOH, KNO₃)

- Ts'ebetso e tsitsitseng ho karabelo ea sulfidation / chlorination

- Ho hanyetsa kutu khahlanong le HF ho fihla ho 800 ° C

- Ho boloka bohloeki ho ntšoa ha lintho tse sa tloaelehang tsa lefatše

Moruo oa Ts'ebetso

Le hoja litšenyehelo tsa pele li phahame ka 40-60% ho feta li-crucible tsa setso, litharollo tsa RBSC li fana ka:

- Phokotso ea 70% ea maqhubu a phetoho

- 25–35% ea ho boloka matla ka ho ntlafatsa ts'ebetso ea mocheso

- 90% e ka sebelisoa hape ka lisebelisoa tsa mocheso

- Litlhoko tsa tlhokomelo e haufi le zero

Lintlafatso tse Ikemetseng tsa Indasteri

1. Tlhahiso ea Titanium Alloy

- E mamella reactive Ti e qhibiliha ho 1700°C

- E thibela tšilafalo ea khabone

2. Battery Material Synthesis

- E nolofalletsa ts'ebetso ea cathode ea LiCoO₂ e tšoanang

- E hanela kutu ea letsoai la lithium

3. Khōlo ea Crystal ea Semiconductor

- E boloka tumellano ea vacuum e phahameng haholo

- E felisa tšilafalo ea silicon carbide

Moqapi oa Bokamoso

Li-crucible tsa sejoale-joale tsa RBSC li kenyelletsa likarolo tse tsoetseng pele:

- Mehaho ea gradient porosity bakeng sa ho kenella ha khase e laoloang

- Liaparo tsa Nanoscale holim'a metsi li matlafatsa khanyetso ea slag

- Li-sensor tse kentsoeng tsa mocheso bakeng sa ho lekola ts'ebetso

Ho tloha lipatlisisong tsa laboratori ho isa tlhahisong ea boima ba indasteri, li-crucibles tsa silicon carbide crucibles li ntse li tsoela pele ho hlalosa bokhoni ba ho sebetsa ka mocheso. Motsoako oa bona o ikhethang oa thepa ea mocheso, ea mochini le ea lik'hemik'hale e ba beha e le khetho ea bohlokoa bakeng sa lisebelisoa tsa mocheso o phahameng oa moloko o latelang, ho khanna ka katleho le ntlafatso ea boleng makaleng a mangata a tsoetseng pele a tlhahiso.

Nako ea poso: Mar-20-2025