1. Corrosion Resistance

Li-nozzles tsa FGDsebetsa libakeng tse senyang haholo tse nang le sulfur oxides, chloride, le lik'hemik'hale tse ling tse mabifi. Silicon carbide (SiC) ceramic e bonts'a khanyetso e ikhethang ea kutu e nang le tahlehelo ea boima bo ka tlase ho 0.1% ho tharollo ea pH 1-14 (ka tlhahlobo ea ASTM C863). Ha ho bapisoa le tšepe e sa hloekang (PREN 18-25) le li-alloys tsa nickel (PREN 30-40), SiC e boloka botšepehi ba sebopeho ntle le ho senya kapa ho senya khatello ea maikutlo esita le ka li-acids tse ngata ka mocheso o phahameng.

2. Botsitso bo Phahameng ba Mocheso

Lithempereichara tse sebetsang lits'ebetsong tsa metsi a phophomang desulfurization hangata li fapana ho 60-80°C le li-spikes tse fetang 120°C. SiC ceramic e boloka 85% ea matla a eona a mocheso oa kamore ho 1400 ° C, li-ceramics tsa alumina tse sebetsang hantle (ho lahleheloa ke matla a 50% ka 1000 ° C) le litšepe tse thibelang mocheso. Thermal conductivity ea eona (120 W/m·K) e thusa ho qhala mocheso hantle, ho thibela ho eketseha ha khatello ea mocheso.

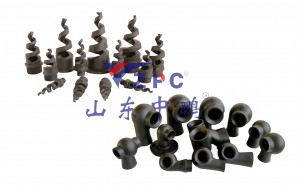

3. Apara Resistance

Ka Vickers e thata ea 28 GPa le ho robeha ho thata ha 4.6 MPa·m¹/², SiC e bonts'a khanyetso e phahameng ea khoholeho khahlano le likaroloana tsa molora oa fofa (Mohs 5-7). Liteko tsa masimong li bonts'a li-nozzles tsa SiC li boloka <5% e apere ka mor'a lihora tse 20,000 tsa ts'ebeletso, ha li bapisoa le 30-40% ea li-nozzles tsa alumina le ho hloleha ho felletseng ha litšepe tse koahetsoeng ke polymer nakong ea lihora tse 8,000.

4. Litšobotsi tsa Phallo

Sebaka se se nang metsi sa SiC e kopantsoeng le reaction (contact angle>100 °) e nolofalletsa ho hasana ka mokhoa o hlakileng oa slurry ka boleng ba CV <5%. Sebaka sa eona se boreleli (Ra 0.2-0.4μm) se fokotsa khatello ea khatello ka 15-20% ha e bapisoa le li-nozzles tsa tšepe, ha e ntse e boloka li-coefficients tse tsitsitseng tsa ho ntša (± 1%) ka nako e telele ea ts'ebetso.

5. Tlhokomelo Bonolo

Ho se sebetse ha lik'hemik'hale tsa SiC ho lumella mekhoa e mabifi ea ho hloekisa ho kenyelletsa:

- Jete ea metsi e nang le khatello e phahameng (ho fihla ho 250 bar)

- Ultrasonic ho hloekisa ka tharollo ea alkaline

- Sterilization ea mouoane ka 150°C

Ntle le kotsi ea ho senyeha ha holim'a metsi ho tloaelehileng ho li-nozzles tsa tšepe tse entsoeng ka polymer kapa tse koahetsoeng.

6. Lifecycle Economics

Le hoja litšenyehelo tsa pele tsa li-nozzles tsa SiC li phahame ka 2-3 × ho feta 316L e tloaelehileng ea tšepe, bophelo ba bona ba tšebeletso ea lilemo tse 8-10 (vs lilemo tse 2-3 bakeng sa tšepe) bo fokotsa makhetlo a 70%. Kakaretso ea litšenyehelo tsa ho ba beng li bonts'a 40-60% ea ho bolokoa nakong ea lilemo tse 10, 'me ha ho na nako ea ho lokisoa ha in-situ.

7. Ho lumellana ha Tikoloho

SiC e bonts'a ts'ebetso e ke keng ea lekanngoa maemong a feteletseng:

- Ho hanyetsa ho fafatsa letsoai: 0% phetoho ea boima ka mor'a tlhahlobo ea 5000hr ASTM B117

- Ts'ebetso ea phoka ea asiti: E mamella mouoane oa 160°C H2SO4

- Ho hanyetsa mocheso oa mocheso: E pholoha 1000 ° C → 25 ° C ho tima lipotoloho

8. Anti-scaling Properties

Sebopeho sa athomo se kopaneng sa SiC se theha sebaka se sa sebetseng se nang le sekhahla sa 80% se tlase ho feta mefuta e meng ea tšepe. Liphuputso tsa Crystallographic li senola hore calcite le gypsum deposits li theha li-bond tse fokolang (ho khomarela <1 MPa) ho SiC khahlanong le> 5 MPa ka tšepe, e leng ho nolofalletsang ho tlosoa ha mechine habonolo.

Sephetho sa Tekheniki

Silicon carbide ceramic e hlaha e le khetho e nepahetseng bakeng sa li-nozzles tsa FGD ka tlhahlobo e felletseng ea ts'ebetso:

- 10 × bophelo bo bolelele ba ts'ebeletso ho feta mefuta e meng ea tšepe

- Phokotso ea 92% ea tlhokomelo e sa reroang

- ntlafatso ea 35% ea katleho ea ho tlosa SO2 ka mekhoa e tsitsitseng ea ho fafatsa

- Ho lumellana ka botlalo le litekanyetso tsa likhase tsa EPA 40 CFR Karolo ea 63

Ka mekhoa e tsoetseng pele ea tlhahiso e kang ea mokelikeli oa mokelikeli le ho roala ha CVD, li-nozzles tsa SiC tsa moloko o latelang li finyella li-sub-micron surface finishes le li-geometri tse rarahaneng tseo pele li neng li sa fumanehe ka lirafshoa. Phetoho ena ea theknoloji e beha silicon carbide e le thepa ea khetho bakeng sa litsamaiso tsa ho hloekisa khase ea flue ea moloko o latelang.

Nako ea poso: Mar-20-2025