Silicon carbide (SiC) ceramicsli tsebahala ka matla a tsona a makatsang, ho hanyetsa mocheso, le ho tšoarella nako e telele. Mehaho ena e etsa hore e be e loketseng ho sebelisoa libakeng tse thata, joalo ka lienjineri tsa sefofane kapa mechini ea indasteri. Empa hantle-ntle lisebelisoa tsee tse tsoetseng pele li entsoe joang? A re qhekelle mokhoa ona mohato ka mohato.

1.Tokisetso ea lintho tse tala

Tsohle li qala ka phofo e phahameng ea silicon carbide. Nahana ka sena e le "phofo" ea ho baka "kuku" ea ceramic. Ho ntlafatsa thepa ea ho qetela, li-additives-joaloka aluminium oxide kapa metsoako ea boron-li kopantsoe. Li-additives tsena li sebetsa joaloka sekhomaretsi nakong ea morao-rao, li thusa hore likaroloana li kopane ka katleho.

2. Ho bōpa Ceramic

Joale phofo e fetoloa hore e be sebopeho se ka bōptjoang. Ho sebelisoa mekhoa e 'meli e tloaelehileng:

Tobetsa: Phofo e hatelloa hore e be sebopeho se ikhethileng ho sebelisoa khatello e phahameng, e ts'oanang le ho kopanya lehloa ka har'a bolo ea lehloa.

Ente ea ho Bopa: Phofo e tsoakoa le sekoahelo sa nakoana (joaloka boka ba boka) ho etsa motsoako o kang hlama, o kenngoa ka har'a hlobo bakeng sa libopeho tse rarahaneng.

Mothating ona, thepa e ntse e fokola—joaloka setšoantšo se betliloeng sa lehlabathe le omeletseng—’me se lokela ho “phehoa” hore se be matla.

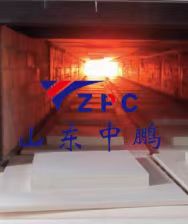

3. The Sintering Process

Mona ke moo boselamose bo etsahalang. Ceramic e bōpehileng joaloka sebōpi e besoa ka sebōping se khethehileng ka mocheso o phahameng haholo (hangata o ka holimo ho 1,800 ° C). Nakong ea sintering, lintho tse peli tsa bohlokoa li etsahala:

Particles Bond: Lithollo tsa silicon carbide li hola haufi, li tlosa likheo mme li theha sebopeho se tiileng.

Mosebetsi oa Li-additives: Metsoako e ekelitsoeng e qhibiliha hanyane, e theha "borokho" lipakeng tsa likaroloana ho matlafatsa boima.

Tikoloho e ka har’a sebōpi e laoloa ka hloko—ka linako tse ling e tlala likhase tse sa sebetseng—ho thibela liketso tse sa batleheng.

4. Ho Qetella Lintho

Ka mor'a ho chesa, ceramic e ka 'na ea fumana phekolo e eketsehileng ho ntlafatsa tshebetso ea eona:

Polishing: Bakeng sa lisebelisoa tse hlokang libaka tse boreleli (mohlala, litiiso kapa li-bearings).

Ho roala: Lera le tšesaane la tšireletso (joaloka silicon nitride) le ka eketsoa ho matlafatsa khanyetso ea ho apara.

Machining: Ho itšeha ka nepo kapa ho cheka ho fihlela litekanyo tsa ho qetela.

Ke Hobane'ng ha Mokhoa ona o le Bohlokoa

Lekunutu la matla a silicon carbide ke hore na liathomo tsa eona li tlamahane joang nakong ea sintering. Mokhoa o phahameng oa mocheso o etsa marang-rang a matla a silicon-carbon bond, a hanyetsanang le mocheso, kutu le khatello ea kelello ea 'mele. Li-additives le taolo e nepahetseng ea mocheso li netefatsa hore sehlahisoa sa ho qetela ha se thata feela empa hape se thata ka ho lekaneng ho thibela ho peperana.

Setšoantšo se Seholo

Ho tloha ho li-turbine tsa morao-rao ho isa lits'ebetsong tsa taolo ea tšilafalo, lirafshoa tsa silicon carbide li bapala karolo ea bohlokoa theknolojing ea sejoale-joale. Le hoja mokhoa oa ho etsa lihlahisoa o rarahane, ke tekanyo ena e hlokolosi ea saense le boenjiniere e fetolang phofo e bonolo hore e be thepa e khonang ho mamella maemo a thata ka ho fetisisa.

Ha lipatlisiso li ntse li tsoela pele, mekhoa e mecha - joalo ka khatiso ea 3D ea lirafshoa - e ea hlaha, e ts'episang ts'ebeliso e ncha ea thepa ena e makatsang.

Nako ea poso: Mar-19-2025