Xidho dahaarka u adkaysta, saxan dahaarka iyo duufaanka loo isticmaalo miinada dhuxusha

Xidho dahaarka u adkaysta, saxan dahaarka iyo duufaanka loo isticmaalo miinada dhuxusha

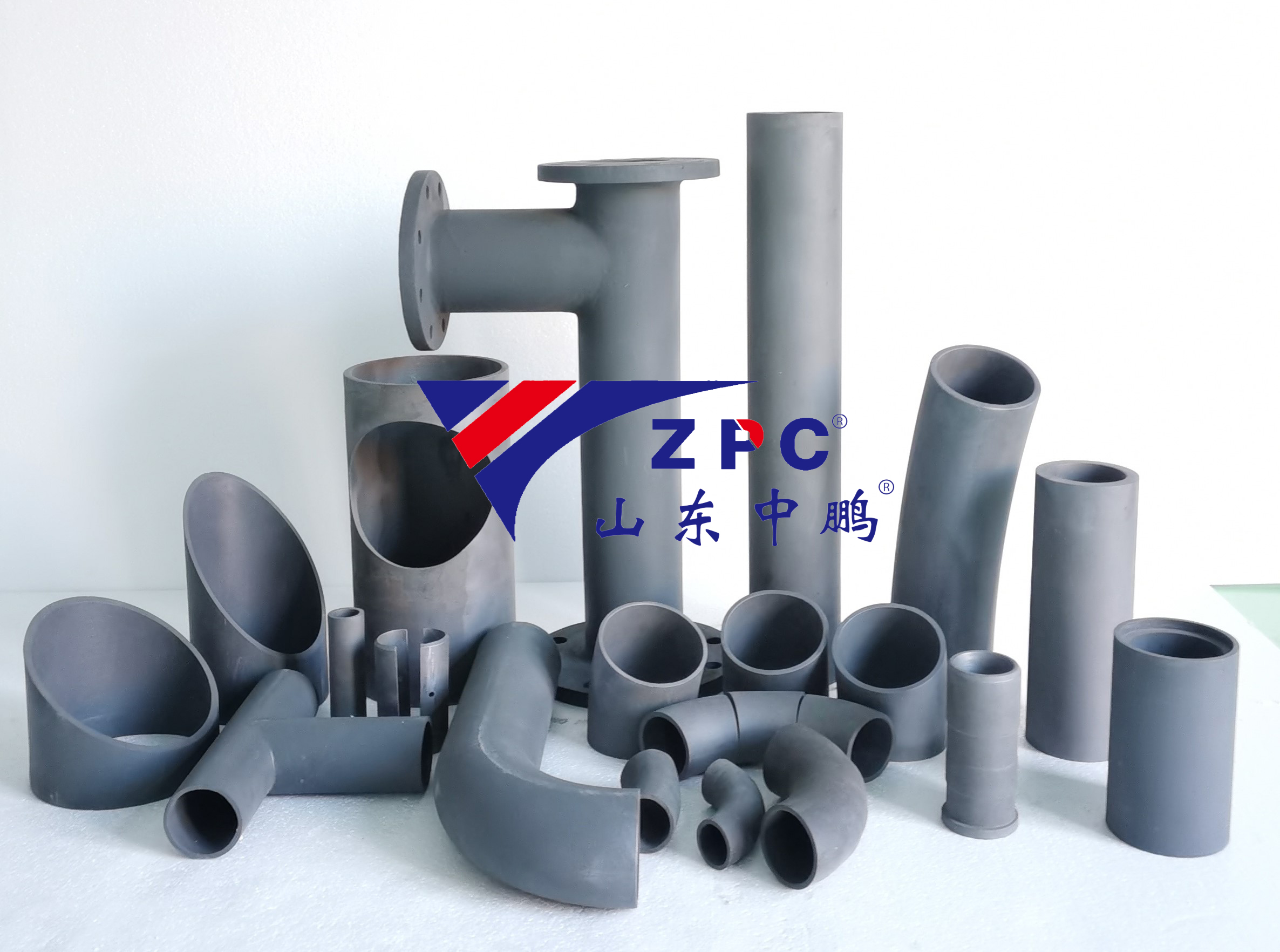

Tuubooyinka dhoobada ee Silicon Carbide:

![]() dhoobada Silicon Carbide waa wax ku habboon xirashada u adkeysiga, taas oo si gaar ah ugu habboon xoqidda xoogga leh, walxaha qallafsan, kala-soocidda, u-fiirsashada, fuuq-baxa iyo hawlgallada kale.

dhoobada Silicon Carbide waa wax ku habboon xirashada u adkeysiga, taas oo si gaar ah ugu habboon xoqidda xoogga leh, walxaha qallafsan, kala-soocidda, u-fiirsashada, fuuq-baxa iyo hawlgallada kale.

Waxaa si weyn loogu isticmaalaa warshadaha macdanta, warshadaha birta, warshadaha warshadaynta shacaab, kiimikaad

warshadaha, warshadaha samaynta alaabta ceeriin, shaabadeynta farsamada, daawaynta sandblasted dusha iyo milicsiga iwm The engegnaantii aadka u fiican iyo caabbinta abrasive, waxa ay si wax ku ool ah u ilaalin kartaa qayb ka mid ah meesha baahida xirashada ilaalinta, si ay u dheereeyaan nolosha adeegga qalabka.

■Tilmaamaha:

| Shayga | Unug | Xogta |

| Heerkulka codsiga | ℃ | 1380 ℃ |

| Cufnaanta | G/cm3 | >3.02 |

| Bannaanka furan | % | 0.1 |

| Xoog laabashada -A | Mpa | 250 (20 ℃) |

| Xoog laabashada -B | MPa | 280 (1200 ℃) |

| Hababka barti-A | GPA | 330 (20 ℃) |

| Hababka barti-B | GPA | 300 (1200 ℃) |

| Dhaqdhaqaaqa kulaylka | W/mk | 45 (1200 ℃) |

| Isku-dhafka ballaarinta kulaylka | K-1 ×10-6 | 4.5 |

| Adag | / | 13 |

| Aashitada aan alkaliinka lahayn | / | heer sare ah |

■Qaabka iyo cabbirrada la heli karo:

Dhumucda: laga bilaabo 6mm ilaa 25mm

Qaabka Joogtada ah: Saxan SISIC, Dhuumaha SISIC, SiSiC Saddex Xidhiidhiye, SISIC Suxulka, SISIC Cone Cyclone.

Fiiro gaar ah: Cabbirrada kale iyo qaabka ayaa la heli karaa marka la codsado.

■Baakad:

Sanduuqa kartoonka, oo lagu soo raray alwaax qiiqaysan oo miisaankiisu yahay 20-24MT/20′FCL.

■Faa'iidooyinka muhiimka ah:

1. Iska caabbinta xirashada heer sare ah, iska caabin saameyn leh iyo iska caabin daxalka;

2. flatness heer sare ah iyo iska caabin heerkul aad u fiican ilaa 1350 ℃

3. Rakibaadda fudud;

4. Nolosha adeegga dheer (waxay ku saabsan tahay 7 jeer in ka badan tan dhoobada alumina iyo 10 jeer in ka badan tan

polyurethane

Naqshadeynta tuubooyinka leh dahaarka dhoobada:

Waxyaabaha dhoobada ah: RBSiC, SiSiC, SSiC, 99.5% alumina, 99% alumina, 95% alumina

- Tubooyinka, wax soo saarka guud ahaan;

- Taarikada, saxan dhalaalaysa

- Tiles, dhoobada dhoobada.

Qaabka xagal raad ku yeelata nabarka xaglaha hoose

Marka qulqulka walaxda xoqan ay ku dhufato dusha dusheeda ee xagal gacmeed ama ay u gudubto barbar-socod, nooca xirashada ee ka dhacda is jiid jiidka waxaa loo yaqaannaa nabar simbiriirixan.

dhoobada silikoon carbide ee sareeysa waxay bixiyaan iska caabin xirashada iyo iska caabinta daxalka dhoobada dhoobada iyo dahaarka Alaabooyinkan ayaa la xaqiijiyay inay xidhmeen qalabka gudbinta, habaynta, iyo habka kaydinta. Tiirarkayada waxaa lagu soo saari karaa dhumucdiisu tahay 8 ilaa 45mm. waa muhiim inaad hubiso inaad heli karto alaabta loo baahan yahay. SiSiC: Adkeeyga Moh waa 9.5 (Aadeegnaanta cusub ee Moh waa 13), oo leh iska caabin aad u wanaagsan oo nabaadguurka iyo daxalka, nabaad-guurka heersare ah - iska caabin iyo anti-oxidation. Waxay 4 ilaa 5 jeer ka xoog badan tahay nitride ku xidhan silikon carbide. Nolosha adeeggu waxay 5 ilaa 7 jeer ka dheer tahay alaabta aluminiumka ah. MOR ee RBSiC waa 5 ilaa 7 jeer ka SNBSC, waxa loo isticmaali karaa qaabab aad u adag. Xidho dahaarka dhoobada adkaysiga u leh si loo horumariyo waxqabadka wax soo saarka, hufnaanta shaqada, dhimista kharashyada dayactirka iyo korodhka faa'iidada.

dhoobada saxda ah waxay leeyihiin aqoonta maadiga, khibrad la dabaqay iyo xirfadaha injineernimada. Tani waxay si wax ku ool ah u xaqiijin kartaa in xalalka ugu fiican la siiyo macaamiisheena. Duubabka dhoobada ah ee Silicon carbide iyo dahaarka ayaa inta badan loo adeegsadaa codsiyada sida duufaanada, tuubooyinka, tuubooyinka, hoppers, tuubooyinka, suumanka qaada iyo nidaamyada wax soo saarka. Nidaamka, waxaa jira walxo dhaqaaqa oo simbiriirixaya dusha sare. Marka shaygu ku dul simbiro shay, si tartiib ah ayuu u xidhaa qaybaha ilaa aanay waxba ka hadhin. Goobaha xirashada sare, tani waxay ku dhici kartaa si joogto ah waxayna sababi kartaa dhibaatooyin badan oo qaali ah. Qaab dhismeedka ugu muhiimsan waxaa lagu hayaa iyadoo la isticmaalayo walxo aad u adag, sida dhoobada silikoon carbide ceramics iyo alumina ceramics sida dahaarka allabariga. Isla mar ahaantaana, dhoobada silikoon carbide ceramics waxay u adkeysan kartaa xirashada dheer ka hor inta aan loo baahnayn in la beddelo, nolosha adeegga dhoobada silikoon carbide waxay 5 ilaa 7 jeer ka dheer tahay walxaha alumina.

Xidho dhoobada dhoobada ee Silicon-carbide ee iska caabinta leh iyo guryaha dahaarka:

Kiimikada adkaysi u leh

Dabci koronto

Nabaadguurka makaanikada & nabaad-guurka u adkaysta

La beddeli karo

Faa'iidooyinka Dufanka iyo Dahaarka u adkaysta Xirashada Ceramic:

Waxa loo isticmaali karaa meelaha dulqaadka adag ama dahaarka khafiifka ah looga baahan yahay

Waxaa loo isticmaali karaa in dib loo soo nooleeyo meelaha u nugul xirashada

Waxa lagu isticmaali karaa habab badan oo ku-xidhka sida alxanka iyo xabagta

Caado loogu talagalay codsiyo gaar ah

Aad u adkaysta daxalka

Xalka dhimista xidhashada khafiifka ah

Waxay ilaalisaa qaybaha dhaqaaqa ee ay ku xiran yihiin bay'ada xirashada sare

Si mug leh uga gudubta & ugana fiicnaado xalalka dhimista xidhashada

Heerkulka isticmaalka ugu sarreeya ee aadka u sarreeya ilaa 1380°C

1. Warshadaha birta

Habka gudbinta: baaldi wheel Bai, disc, hopper Du, silo, koofida suunka qaada, teeriga trolley, qaadashada hopper

Nidaamka Duubista: isku dhafka silo, dhululubada isku dhafka hoose ee Dao, dhululubada isku dhafka labaad, saxanka qaska, durbaanka qaska, xoqida, saxan bir ah

Nidaamka sintering: faa'iidada hopper ee shaashadda gariirta hoosteeda, alaabta ceeriin gaadiidka, ururiyaha boodhka duufaanka iyo dhuumaha, marawaxad

2. Warshadaha sibidhka:

Nidaamka burburinta nuuradda iyo ceyriinka iyo shidaalka ka hor nidaamka homogenization: chute, hopper, durbaan suunka

Habka wax-shiidka ceeriin: weelka hagaha kala-soocida, koorta kala-soocida, mishiinka toosan ee tuubada duufaanka, duufaanta, warshada shidaalka (birta kubad-shiidka), guryaha kala-soocida, koofida gudaha, tuubada dhuxusha oo miirtay

Shidaalka shiididda (kubbada birta): Guryaha kala soocida, koofiyadda gudaha, dhuumaha dhuxusha oo miirmay, tuubada soo celinta budada

3. Warshadaha dekedaha

Hopper go'an oo loogu talagalay meesha la seexdo, hopper mashiinka giraangiraha baaldiga, hopper ee rugta wareejinta suunka, hopper dejinta markabka

4. Warshadaha dhalada

Habka gudbinta: madaxa chute, silo (biinka dhexe, bin dabada), weelka shaashadda gariiraya, kookaha hopper, metering hopper

Nidaamka Duubista: hopper batching, aasaasiga ah (sare) qasiyaha

Habka dubista: hal bamka biinka ah, tuubada calcine, hopper batching, dambas hopper, dhexdhexaadiyaha bin hopper

5. Warshadaha Kiimikada:

Habka gudbinta: hopper, silo

Nidaamka ka saarida siigada: tuubada ka saarida siigada, xusulka, daboolka marawaxada iyo impeller, duufaan

6. Warshadaha dhuxusha:

Nidaamka maaraynta dhuxusha: shute, hopper, silo

Habka dhaqida dhuxusha: duufaan la cadaadisay, cadaadis aan cadaadis lahayn saddex wax soo saar duufaan dhexdhexaad ah oo culus, cadaadis aan cadaadis afar alaab oo culus oo dhexdhexaad ah, kooxda duufaannada

Habka gudbinta: dhuumaha, xusulka, tuubada, hopper, silo, dekedda qaybinta

7. Warshadaha macdanta:

Habka gudbinta: hopper silo

Ceramics Refractory

Xidho iska caabin

Kala soocidda Miinada Duufaanta

Isku dhafka PU

Isku-dhafka Polyurethane

Sisic Lined steel

dhoobada refractory

Kasbada ilaalinta SISIC

RBSIC gacanka ilaalinta

Silicon Carbide Burner Nozzle

Tuubada Silikoon Carbide

Qalabka E-Sigaarka

Ceramics Refractory

Furniture-ka

Cadaadiska Heerkulka Sare

Dareen-celinta Silicon Carbide

Qalabka ilaalinta militariga

Daloolinta ka hortagga

Ilaalinta nabarrada

iska caabin ah

Birta Aan Lahayn

Waxa lagu sameeyay Shiinaha Xiro-iska-caabbinta Ceramics Compound Polyurethane

Shiinaha Compound PU

Shiine Compound Polyurethane

Alumina Ceramic

Tube

1650c Heerkul Sare Sic Tube

Waxa lagu sameeyay Shiinaha Xiro-iska caabbinta dhoobada isku dhafan PU

Presicion Sare Silicon Carbide Ceramics

Silicon Carbide Giraanta Nadiifinta Sare

Qaybaha dhoobada Silicon-Carbide ee aan joogtada ahayn

Qaybaha dhoobada

Qalabyada dhoobada ee Silicon Carbide

Agabka dhoobada

Waxa lagu sameeyay Shiinaha Xiro-iska-caabbinta dhoobada Isku-dhafka ah ee Sisic-ka Leh

Qaybta dhoobada

Waxa lagu sameeyay Shiinaha Jumlo shahaado la aqoonsan yahay xidhashada-iska-caabbinta dhoobada polyurethane

Adagnimada Sare

92% aluminium

Waxa lagu sameeyay Shiinaha Wear Warshadaha-iska-caabbinta dhoobada isku dhafan ee Polyurethane

Shandong Zhongpeng Ceramics Co., Ltd waa mid ka mid ah xalalka alaabta cusub ee silikoon carbide ugu weyn ee Shiinaha. dhoobada farsamada ee SiC: Adkeeyga Moh waa 9 (Adayga cusub ee Moh waa 13), oo leh iska caabin aad u wanaagsan oo nabaadguurka iyo daxalka, nabaad-guurka aad u fiican - iska caabbinta iyo anti-oxidation. Nolosha adeegga sheyga SiC waa 4 ilaa 5 jeer in ka badan 92% walxo aluminium ah. MOR ee RBSiC waa 5 ilaa 7 jeer ka SNBSC, waxa loo isticmaali karaa qaabab aad u adag. Habka xigashada waa mid degdeg ah, gaarsiinta waa sidii balanta ahayd, tayaduna waa labaad ee midna. Had iyo jeer waxaan ku adkaysannaa inaan ka hortagno yoolalkayaga oo aan dib u soo celinno quluubtayada bulshada.