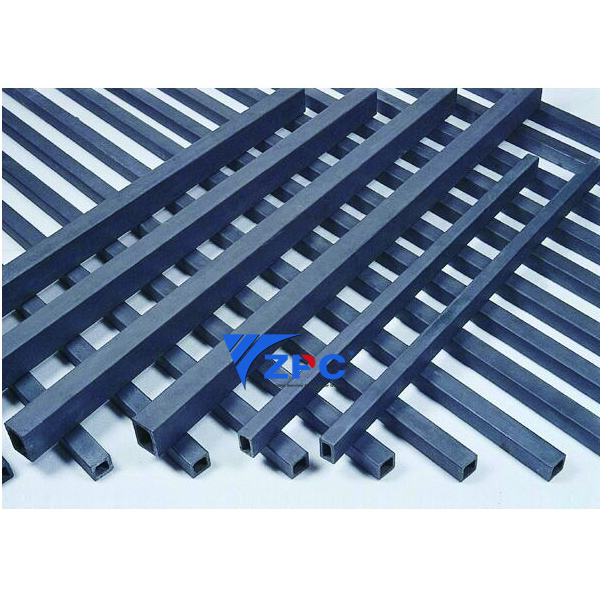

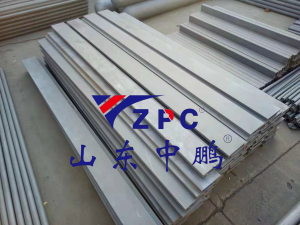

SiC Beams

Isku-xidhka Falcelinta Silicon Carbide Xoog Sare Toosanaan Sisic/ Rbsic Rollers iyo Biams

Reaction sintering silicon carbide ceramics roller waxaa inta badan loo isticmaalaa warshadaha baytariyada lithium, suufka maalinlaha ah, dhoobada fayadhowrka, dhoobada dhismaha iyo alaabta magnetic, sida giraangiraha rullaluistemadka, gubasho heerkul sare leh kiln ku habboon, oo leh nolol adeeg dheer. Waxay leedahay awood heerkul sarreeya, caabbinta shoogga kulaylka, iska caabin heerkul sare ah, iska caabin xoog leh, caabbinta xirashada wanaagsan.

Naadiyadu waxay khuseeyaan maalin kasta - dhoobada la isticmaalo, dhoobada fayadhowrka, dhoobada dhismaha, walxaha magnetic iyo heerkulka sare ee aagga giraanta rullaluleyda.

| Tilmaamaha Alaabta Silicon Carbide: | ||||

| Shayga | Unug | SSIC | RBSIC SISIC | R-SIC |

| daahirnimo | (%) | ≥ 99 | ≥90% | ≥ 99 |

| heerkulka codsiga | ºC | 1700 | 1380 | 1650 |

| Cufnaanta | g/CM2 | ≥3.10-3.15 | ≥3.02 | 2.65-2.75 |

| Bannaanka furan | % | ≤0.1 | ≤0.1 | |

| Adag | ≥92 HRA | 2400 Kg/mm2 | 1800-2000 Kg/mm2 | |

| Xoog laabashada | MPa | 400-580 | 250 (20ºC) | ≥300 |

| 281 (1200ºC) | ||||

| Xoog xajin | Mpa | ≥200 | ≥190 | |

| modules ee barti | GPA | 400 | 332 (20ºC) | 80-100 (20ºC) |

| 300 (1200ºC) | 90-110 (1200ºC) | |||

| Habdhaqanka kulaylka | W/mk | 100-120 | 45 (1200ºC) | 36 |

| Isku-dhafka ballaarinta kulaylka | K1X 106 | 4.2 | 4.5 | 4.6 |

| Adag | Gpa | >25 | 13 | |

| Acid&Ikali iska caabin | Aad u fiican | Aad u fiican | Aad u fiican | |

| Sicida Alaabta: | ||||

| Shayga | Unug | OC-1 | OC-2 | MC-3 |

| SiC | (%) | ≥90 | ≥86 | ≥80 |

| Muuqda Porosity | (%) | ≤10 | ≤13 | ≤16 |

| Cufnaanta | g/CM2 | ≥2.66 | ≥2.63 | ≥2.6 |

| heerkulka codsiga | ºC | ≥1680 | ≥1620 | ≥1550 |

| Isku-dhafka ballaarinta kulaylka | aX 10-6/ºC | ≤4.8 | ≤5.0 | ≤5.5 |

| Xoog Laabashada | 1200ºC | ≥45 | ≥40 | ≥30 |

Shandong Zhongpeng Ceramics Co., Ltd waa mid ka mid ah xalalka alaabta cusub ee silikoon carbide ugu weyn ee Shiinaha. dhoobada farsamada ee SiC: Adkeeyga Moh waa 9 (Adayga cusub ee Moh waa 13), oo leh iska caabin aad u wanaagsan oo nabaadguurka iyo daxalka, nabaad-guurka aad u fiican - iska caabbinta iyo anti-oxidation. Nolosha adeegga sheyga SiC waa 4 ilaa 5 jeer in ka badan 92% walxo aluminium ah. MOR ee RBSiC waa 5 ilaa 7 jeer ka SNBSC, waxa loo isticmaali karaa qaabab aad u adag. Habka xigashada waa mid degdeg ah, gaarsiinta waa sidii balanta ahayd, tayaduna waa labaad ee midna. Waxaan had iyo jeer ku adkeysaneynaa inaan ka hortagno yoolalkayaga oo aan dib u soo celinno quluubtayada bulshada.