Sanadihii la soo dhaafay, semiconductors-ka silikoon carbide waxay heleen dareen baahsan warshadaha. Si kastaba ha ahaatee, sida maaddada waxqabadka sare leh, silikoon carbide waa qayb yar oo ka mid ah qalabka elektaroonigga ah (diodes, qalabka korontada). Waxa kale oo loo isticmaali karaa sida abrasives, alaabta goynta, qalabka qaab-dhismeedka, qalabka indhaha, sidayaal kicinta, iyo in ka badan. Maanta, waxaan inta badan soo bandhignaa dhoobada silikoon carbide, kuwaas oo leh faa'iidooyinka xasiloonida kiimikada, iska caabbinta heerkulka sare, xirashada caabbinta, iska caabinta daxalka, kuleylka sare ee kuleylka, iskudhafka ballaarinta kulaylka hooseeya, cufnaanta hoose, iyo xoogga farsamada sare. Waxaa si weyn loogu isticmaalaa beeraha sida mashiinka kiimikada, tamarta iyo ilaalinta deegaanka, semiconductors, metallurgy, difaaca qaranka iyo warshadaha military.

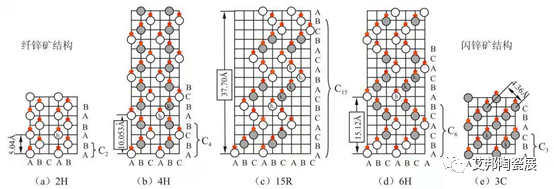

Silikon carbide (SiC)waxaa ku jira silikoon iyo kaarboon, waana qaab dhismeedyo kala duwan oo caadi ah, oo ay ku jiraan laba nooc oo crystal ah: α - SiC (nooca deggan heerkulka sare) iyo β - SiC (nooca deggan heerkulka hoose). Waxaa jira in ka badan 200 oo noocyo badan ah, kuwaas oo ay ka mid yihiin 3C SiC ee β - SiC iyo 2H SiC, 4H SiC, 6H SiC, iyo 15R SiC ee α - SiC ayaa wakiil ka ah.

Jaantuska Qaabdhismeedka Jidhka Badan ee SiC

Marka heerkulku ka hooseeyo 1600 ℃, SiC waxay u jirtaa qaab β-SiC waxaana laga diyaarin karaa isku dhafka silikoon iyo kaarboon qiyaastii 1450 ℃. Marka heerkulku dhaafo 1600 ℃, β - SiC si tartiib tartiib ah isu beddesha polymorphs kala duwan ee α - SiC. 4H SiC si fudud ayaa loo soo saaray agagaarka 2000 ℃; Labada 6H iyo 15R polymorphs waxay u baahan yihiin heerkul sare oo ka sarreeya 2100 ℃ si sahlan loo sameeyo; 6H SiC waxay ahaan kartaa mid aad u xasilloon xitaa heerkulka ka sarreeya 2200 ℃, taasoo ka dhigaysa mid si ballaaran loogu isticmaalo codsiyada warshadaha.

Carbide silikoon saafi ah waa crystal aan midab lahayn oo hufan, halka carbide silikoon warshadu noqon karto mid aan midab lahayn, jaale cirro leh, cagaar iftiin ah, cagaar madow, buluug khafiif ah, buluug madow, ama xitaa madow, oo leh hoos u dhac ku yimaada daahfurnaanta. Warshadaha abrasive waxay u kala saaraan silikoon carbide laba nooc oo ku salaysan midab: carbide silicon madow iyo carbide silicon cagaaran. Kaarbide silikoon oo cagaar ah oo aan midab lahayn ama madaw waxaa lagu kala saaraa silikoon carbide cagaaran, halka buluug khafiif ah ilaa silikoon kaarbiide madow loo kala saaray inuu yahay carbide silikoon madow. Carbide silikoon madow iyo carbide silikoon cagaaran labaduba waa alfa SiC hexagonal crystals, iyo budada yar yar ee silikoon carbide waxaa guud ahaan loo isticmaalaa sida alaabta ceeriinka ah ee silikoon carbide ceramics.

Waxqabadka Ceramics Silicon Carbide oo ay diyaariyeen habab kala duwan

Si kastaba ha noqotee, ceramics-ka silikoon carbide waxay leeyihiin faa'iido darrada adkaanta jabka hooseeya iyo jajabnaanta sare. Sidaa darteed, sannadihii la soo dhaafay, dhoobada isku dhafan ee ku salaysan dhoobada silikoon carbide, sida fiber (ama whisker) xoojinta, xoojinta qaybinta kala duwan ee kala duwan, iyo qalabka shaqada ee gradient, ayaa si isdaba-joog ah u soo baxay, hagaajinta adkaanta iyo xoogga alaabta shakhsi ahaaneed.

Sida wax qabad heer sare ah oo qaab-dhismeed heerkul sare leh, dhoobada silikoon carbide ayaa si sii kordheysa loogu dabaqay foornada heerkulka sare, birta birta, kiimikooyinka batroolka, elektiroonigga farsamada, hawada hawada, tamarta iyo ilaalinta deegaanka, tamarta nukliyeerka, baabuurta iyo meelaha kale.

Sannadka 2022, cabbirka suuqa ee dhoobada qaab dhismeedka silikoon carbide ee Shiinaha ayaa la filayaa inuu gaaro 18.2 bilyan yuan. Iyada oo ballaarinta dheeriga ah ee goobaha dalabka iyo baahiyaha koritaanka hoose, waxaa lagu qiyaasaa in cabbirka suuqa ee dhoobada qaab dhismeedka silikoon carbide uu gaari doono 29.6 bilyan yuan marka la gaaro 2025.

Mustaqbalka, iyada oo la kordhinayo heerka dhexgalka ee baabuurta tamarta cusub, tamarta, warshadaha, isgaarsiinta iyo beeraha kale, iyo sidoo kale shuruudaha sii kordheysa ee adag ee saxnaanta sare, caabbinta xirashada sare, iyo isku hallaynta sare qaybaha farsamo ama qaybaha elektarooniga ah ee beeraha kala duwan, size suuqa ee alaabta dhoobada carbide silicon carbide ayaa la filayaa in ay sii wadaan si ay u ballaariyaan, oo ay ku jiraan baabuurta tamarta cusub iyo photovoltaics yihiin meelaha horumarinta muhiimka ah.

Ceramics-ka Silicon carbide waxaa loo isticmaalaa foornada dhoobada sababtoo ah sifooyinkooda heerkul sare ee farsamada, caabbinta dabka, iyo caabbinta shoogga kulaylka. Waxaa ka mid ah, kilns-ka rullaluistuyada waxaa inta badan loo isticmaalaa qalajinta, sintering, iyo daaweynta kulaylka ee baytariga lithium-ion qalab koronto togan, qalabka korantada taban, iyo electrolytes. Batariyada lithium-ka togan iyo walxaha korantada taban ayaa lagama maarmaan u ah baabuurta tamarta cusub. Qalabka foornada dhoobada ee Silicon carbide waa qayb muhiim ah oo ka mid ah foornada, taas oo hagaajin karta awoodda wax-soo-saarka foornada waxayna si weyn u yareyn kartaa isticmaalka tamarta.

Alaabta dhoobada ah ee loo yaqaan 'Silicon carbide ceramics' ayaa sidoo kale si ballaaran loogu isticmaalaa qaybaha baabuurta ee kala duwan. Intaa waxaa dheer, aaladaha SiC waxaa inta badan lagu isticmaalaa PCUs (cutubyada kontoroolka korantada, sida dusha sare ee DC/DC) iyo OBC-yada (cutubyada dallaca) ee baabuurta tamarta cusub. Aaladaha SiC waxay yareyn karaan miisaanka iyo mugga qalabka PCU, waxay yareeyaan khasaaraha beddelka, waxayna wanaajiyaan heerkulka shaqada iyo hufnaanta nidaamka qalabka; Waxa kale oo suurtogal ah in la kordhiyo heerka awoodda cutubka, la fududeeyo qaab dhismeedka wareegga, hagaajinta cufnaanta awoodda, iyo kordhinta xawaaraha ku dallaca inta lagu jiro dallacaadda OBC. Waqtigan xaadirka ah, shirkado badan oo baabuur oo adduunka ah ayaa u adeegsaday silikoon carbide noocyo badan, iyo qaadashada baaxadda weyn ee carbide silicon waxay noqotay isbeddel.

Marka dhoobada silikoon carbide loo isticmaalo sida walxaha muhiimka ah ee habka wax soo saarka ee unugyada photovoltaic, alaabta ka soo baxda sida taageerada doonyaha, sanduuqyada doonyaha, iyo tuubooyinka tuubooyinka waxay leeyihiin xasillooni kuleyl oo wanaagsan, ha qalloocin marka loo isticmaalo heerkul sare, hana soo saarin wasakhaha waxyeellada leh. Waxay bedeli karaan taageerrada doon quartz ee sida caadiga ah loo isticmaalo, sanduuqyada doonyaha, iyo qalabka tuubooyinka, waxayna leeyihiin faa'iidooyin qiimo leh.

Intaa waxaa dheer, rajada suuqa ee qalabka korontada silikoon carbide ee sawir-qaadista ayaa ah mid ballaaran. Alaabta SiC waxay ku yar tahay iska caabbinta, kharashka albaabka, iyo soo celinta sifooyinka kharashka soo kabashada. Isticmaalka SiC Mosfet ama SiC Mosfet oo lagu daray SiC SBD photovoltaic inverters waxay kordhin kartaa wax ku oolnimada beddelka min 96% ilaa in ka badan 99%, waxay yaraynaysaa khasaaraha tamarta in ka badan 50%, waxayna kordhisaa wareegga qalabka nolosha 50 jeer.

Isku-dubaridka dhoobada silikoon carbide waxa dib loo raadin karaa ilaa 1890-meeyadii, markii silikoon carbide inta badan loo isticmaali jiray qalabka wax lagu shiidi karo iyo walxaha dib-u-celinta. Horumarinta tignoolajiyada wax soo saarka, alaabada SiC-da ee tignoolajiyada sare ayaa si weyn loo horumariyay, wadamada adduunka oo dhan ayaa fiiro gaar ah u leh warshadaynta dhoobada horumarsan. Kuma qanacsana diyaarinta ceramics carbide silicon dhaqameed. Shirkadaha soo saara ceramics-ka tignoolajiyada sare ayaa si xawli ah u koraya, gaar ahaan wadamada horumaray oo ay dhacdadani aad muhiim ugu tahay. Warshadaha ajnabiga ah waxaa ka mid ah Saint Gobain, 3M, CeramTec, IBIDEN, Schunk, Narita Group, Toto Corporation, CoorsTek, Kyocera, Aszac, Japan Jingke Ceramics Co., Ltd., Japan Special Ceramics Co., Ltd., IPS Ceramics, iwm.

Horumarka silikon carbide ee Shiinaha ayaa ahaa mid soo daahay marka loo eego wadamada horumaray sida Yurub iyo Ameerika. Tan iyo markii foornada warshadeed ee ugu horreysay ee wax-soo-saarka SiC laga dhisay Warshadii Farsamada Shiidaalka Koowaad bishii Juun 1951, Shiinuhu wuxuu bilaabay soo saarista carbide silicon. Soosaarayaasha gudaha ee dhoobada silikoon carbide waxay inta badan ku urursan yihiin Magaalada Weifang ee Gobolka Shandong. Sida laga soo xigtay xirfadlayaasha, tani waa sababta oo ah shirkadaha maxalliga ah ee ka shaqeeya qodista dhuxusha ayaa wajahaya khasaare waxayna raadinayaan isbeddel. Shirkadaha qaarkood waxay soo saareen qalab ku habboon Jarmalka si ay u bilaabaan cilmi-baarista iyo soo saarista carbide silicon.ZPC waa mid ka mid ah soo saaraha ugu weyn ee falcelinta sinteed carbide silicon.

Waqtiga boostada: Nov-09-2024