1. Inoshandiswa kune matombo anokosha

Muindasitiri yematombo anokosha, silicon carbide inozivikanwawo se "moissanite". Zvinhu zvinowanzoonekwa pamusika zvakagadzirwa zvekugadzira moissanite, nepo moissanite yechisikigo isingawanzo shomeka, zvekuti yaingoonekwa mumameteorite craters makore 50000 apfuura.

(1) Yakakwira tembiricha yekudzivirira zvigadzirwa:

Uchishandisa hunhu hwekusaita ngura, kupisa kwekushisa kwepamusoro, kusimba kwepamusoro, kunaka kwekushisa kwekushisa, uye kupikisa kwesilicon carbide zvinhu, zvinogona kushandiswa kune akasiyana-siyana ekunyungudutsa simbi yekunyungudutsa, yepamusoro-tembiricha yevira, silicon carbide ndiro, lining ndiro, zvitsigiro, uye ladles. Kune rumwe rutivi, kupisa-kupisa kusina kunanga kupisa zvinhu zvinogona kushandiswa mune isiri-ferrous simbi yekunyungudutsa indasitiri, senge vertical distillation furnaces, arc plates ye zinc powder furnaces, thermocouple protection tubes, nezvimwewo; Inoshandiswa kugadzira advanced silicon carbide ceramic zvinhu zvinopfekwa, zvisingaite ngura, uye inodzivirira tembiricha yepamusoro; Inogonawo kushandiswa kugadzira rocket nozzles, gas turbine blades, etc. Mukuwedzera, silicon carbide zvakare imwe yezvinhu zvakanakisisa zvemagetsi ezuva remvura mumigwagwa mikuru, migwagwa yendege, etc. Nokudaro, silicon carbide inewo zita rinowanzozivikanwa re "jecha refractory", iyo, kunyange zvazvo yakajairika, inonyatsoratidza zvinhu zvayo zvinoramba.

(2) Pfeka zvinodzivirira uye zvinodzivirira corrosion zvigadzirwa:

Kunyanya nekuti silicon carbide ine kuomarara kwepamusoro, nekuomarara kweMohs kwe9.2-9.8, yechipiri chete kune dhaimondi rakaoma kwazvo repasi (level 10), inowanzozivikanwa se "gold steel sand". Iinewo kugadzikana kwakanaka kwemakemikari uye kumwe kuoma, uye inogona kushandiswa kugadzira mavhiri ekukuya, sandpaper, mabhandi ejecha, matombo emafuta, matombo ekukuya, kukuya misoro, kugaya mapete, uye kukuya nekupukuta monocrystalline silicon, polycrystalline silicon, uye piezoelectric makristasi muindasitiri yemagetsi mune zvigadzirwa zvemaziso.

(3) Metallurgical raw materials:

Silicon carbide inogona kushandiswa se deoxidizer yekugadzira simbi uye modifier yekukanda simbi chimiro. Inogona zvakare kushandiswa seyakabikwa yekugadzira silicon tetrachloride uye ndiyo yakanyanya mbishi zvinhu zveiyo silicone resin indasitiri. Silicon carbide deoxidizer rudzi rutsva rwe deoxidizer yakasimba inoumbwa inotsiva yechinyakare silicon poda uye kabhoni poda ye deoxidation. Kuenzaniswa nemaitiro ekutanga, ine yakanyanya kugadzikana yemuviri nemakemikari zvinhu, yakanaka deoxidation mhedzisiro, yakapfupikiswa deoxidation nguva, yakachengetedzwa simba, yakagadziridzwa kugadzirwa kwesimbi, yakagadziridzwa simbi yemhando, kuderedzwa kwekushandisa mbishi, kuderedzwa kusvibiswa kwezvakatipoteredza, kuvandudzwa kwemamiriro ekushanda, uye kuwedzeredzwa kwakazara kwehupfumi hwemavira emagetsi, izvo zvese zvine kukosha kwakakosha.

3, Silicon carbide optical reflector zvinhu

Ceramic zvinhu zvinogadzirwa uchishandisa akakosha mabasa eceramics maererano nehunhu hwemuviri senge ruzha, mwenje, magetsi, magineti, uye kupisa anonzi anoshanda ceramics. Kune marudzi akasiyana-siyana emakeramiki ekushanda ane kushandiswa kwakasiyana, uye silicon carbide inonyanya kushandiswa segirazi rinoratidzira zvinhu mumunda wekeramics inoshanda. SiC ceramics ine yakanyanya kuomarara kuomarara, yakanaka yekupisa uye kugadzikana kwemakemikari, yakaderera thermal deformation coefficient, uye kuramba kune space particle irradiation. Kuburikidza nemaitiro akakosha ekugadzira, miviri yegirazi yakareruka inogona kuwanikwa.

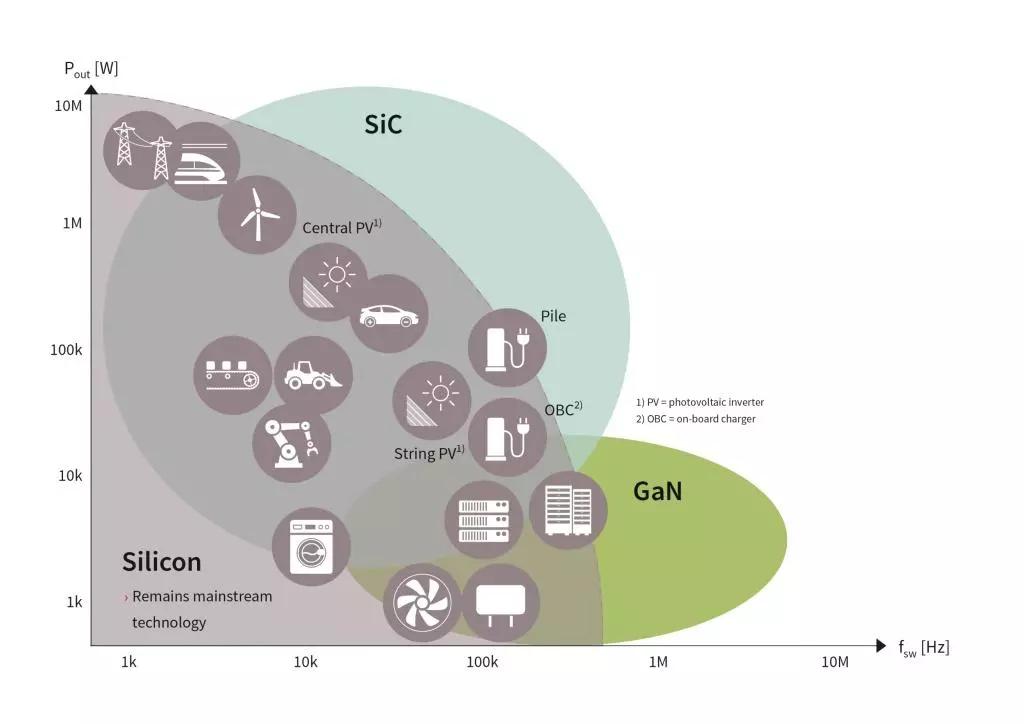

4, Semiconductor zvinhu

Chizvarwa chechitatu semiconductor chinhu chakakosha chakakosha uye chikamu chemagetsi chinotsigira hunyanzvi, kusimudzira, shanduko uye kuvandudzwa kwezvombo zvekudzivirira kwenyika, 5G nharembozha, Internet simba, mota nyowani, njanji uye mamwe maindasitiri. Nekuda kwebasa rayo rakakosha mukuchengetedzwa kwenyika, kugadzira zvine hungwaru, kusimudzira maindasitiri, kuchengetedza simba uye kuderedzwa kwekubuda kwemhepo uye zvimwe zvakakura zvinodikanwa, yave kuve iyo tekinoroji yekuraira nzvimbo yemakwikwi munyika.

SiC, seyakajairwa mumiriri wechitatu-chizvarwa semiconductor zvinhu, parizvino imwe yeyakakura uye yakashandiswa zvakanyanya yakafara bandgap semiconductor zvinhu mukristaro kugadzira tekinoroji uye kugadzira mudziyo. Yakagadzira zvinhu zvepasi rose, mudziyo, uye indasitiri yemashandisirwo ketani. Iyo yakanaka semiconductor zvinhu zvekumusoro-tembiricha, yakakwirira-frequency, radiation inodzivirira, uye yakakwirira-simba maapplication. Nekuda kwekudzikisira kwakakosha kwekushandiswa kwesimba kwemidziyo yemagetsi, silicon carbide magetsi emagetsi anozivikanwawo se "green energy zvishandiso" kutyaira "itsva simba shanduko".

5. Inosimbisa uye inoomesa mumiriri

Pamusoro pezvishandiso zviri pamusoro apa, silicon carbide ndebvu kana silicon carbide faibha yakashandiswa zvakanyanya seyakanakisa yekusimbisa uye inoomesera vamiririri mune inoumbwa zvinhu zvine simbi yakavakirwa kana ceramic zvinhu zvakavakirwa muminda senge muchina, makemikari engineering, kudzivirira kwenyika, simba, uye kuchengetedza kwezvakatipoteredza.

Nguva yekutumira: Mar-22-2025