Munzvimbo yeindasitiri umo tembiricha yakakwira, ngura, uye kupfeka zvinogara pamwe chete, dambudziko rekugara kuchitsiviwa kwepombi dzesimbi dzechinyakare riri kuputswa nepombi itsva yezvinhu -silicon carbide kupfeka-resistant mapaipi, nehunhu hwavo hwakasiyana hwezvinhu, zvakakonzera shanduko yetekinoroji muhurongwa hwekutapurirana mumunda weindasitiri.

1, Kuita kwakanakisa kudarika miganhu yezvinhu zvechinyakare

Silicon carbide kupfeka-resistant pombi dzakaratidza mashandiro anoshamisa murabhoritari kusimbiswa: Vickers kuomarara kwe2800HV kunokwanisa kumira nekukukurwa kunoramba kuripo kubva kujecha redhaimani, uye mumararamiro ekufambisa hupfu muzvidyarwa zvemagetsi ekupisa, hupenyu hwavo hwesevhisi hurefu zvakapetwa kagumi neshanu kupfuura mapaipi echinyakare alloy.

Mukuyedzwa kwemamiriro ekunze tembiricha, mapaipi esilicon carbide anochengetedza kutendeseka kwepamusoro patembiricha ye1350 ℃, iine tembiricha yekuwedzera kwemafuta chete chikamu chimwe muzvitatu chesimbi isina tsvina. Zvinoenderana nemakesi ekushandisa, mukuenderera mberi kwekufambisa kwepamusoro-tembiricha simbi zvidimbu, pombi yanga ichimhanya ichienderera kwe8000 maawa pasina deformation kana kuputika.

Mukupindura dambudziko rakasimba rekuora muindasitiri yemakemikari, silicon carbide zvinhu zvinoita zvakanaka muyakaomeswa sulfuric acid. Data inoratidza kuti pasi pemamiriro ekushanda akafanana, hupenyu hwesevhisi yesilicon carbide pombi ndeye 8.2 nguva yetitanium alloy pombi.

2、 Tekinoroji kubudirira mune zvakayambuka indasitiri zvikumbiro

Mumutsara wekugadzira wezvakanaka electrode zvinhu zvelithium mabhatiri, silicon carbide yakatwasuka pombi inogadzirisa dambudziko rekufambisa mune yakakwirira-tembiricha calcination process. Huremu hwayo huremu hunonatsiridza zvakanyanya kuisirwa kushanda zvakanaka, pamwe neakakosha conductive dhizaini, nekubudirira kubvisa static magetsi njodzi mukugadzira maitiro.

Iko kushandiswa mumunda wemigodhi kunowedzera kubudirira: Mushure memhangura yekubatsiridza chirimwa chakagamuchira silicon carbide composite mapaipi, kutenderera kwekutenderera kwe slurry transveing system kwakawedzera zvakanyanya, izvo zvakachengetedza zvakanyanya mari yekugadzirisa.

3, Kuenderera mberi kwekushanduka kwemaitiro chaiwo ekugadzira

Iyo 2-mita yakabatanidzwa yakaumbwa pombi inogadzirwa uchishandisa reaction sintering tekinoroji inotyora nepakati pekukura kwezvikamu zvechinyakare zveceramic. Kuburikidza ne gradient sintering process control, iyo chaiyo machining level yepombi madziro ukobvu kukanganisa kunoderedzwa.

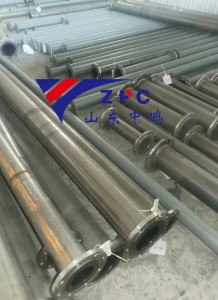

Parizvino, isu takavakirwa pakushandira pamwe kwebhizinesi rechikoro uye kubatana nemayunivhesiti epamusoro kugadzira zvigadzirwa zvemhando yepamusoro zvesilicon carbide ceramic zvinosangana nezvinodiwa zvakasiyana-siyana zvevashandisi, zvinosanganisira silicon carbide kusapfeka-resistant pombi.

Munguva itsva yeindasitiri, silicon carbide kupfeka-inodzivirira pombi haisati ingori mhinduro yekutsiva zvinhu, asi chinhu chakakosha chinotyaira kukwidziridzwa kwehungwaru kwemaindasitiri ezvekuita. Iko shanduko yezvinhu, kubva pakutakurwa kwezvinhu zvemafekitori akangwara kuenda kuzvinhu zvakakosha zvemidziyo yesimba idzva, iri kutsanangura patsva zviyero zvekuvimbika kwekufambiswa kwemaindasitiri. Isu tinoenderera mberi nekurima hunyanzvi hwekugadzira zvinhu uye takazvipira kupa zvigadziriso zvemaindasitiri akasiyana, tichibatsira vatengi kuvaka masisitimu ekugadzira anoshanda uye akasimba.

Kana iwe uchifarirawo zvigadzirwa zvedu, ndapota shanya [Shandong Zhongpeng] kuti uwane rumwe ruzivo rwechigadzirwa, kana kufona (+86)15254687377 kuti uite nguva yekuongororwa kwesimba rinoshanda pamutsara wekugadzira - ngatishandei pamwe, tiwane kuhwina-hwina kubatana, uye kutanga chitsauko chitsva mundima yeindasitiri.

Nguva yekutumira: Kubvumbi-01-2025