Sechinhu chakakosha chemazuva ano flue gasi yekuchenesa masisitimu,silicon carbide FGD Nozzleskuita basa rakakosha mumaindasitiri akadai sesimba rekupisa uye simbi. Iyi silicon carbide ceramic nozzle yakabudirira kugadzirisa iyo tekinoroji bhodhoro rechinyakare simbi nozzles pasi pekuora kwakasimba uye yakakwirira kupfeka mamiriro kuburikidza nehunyanzvi hwekugadzira dhizaini uye kubudirira kwezvinhu, kuvandudza zvakanyanya desulfurization kunyatsoita.

1, Material properties inoisa hwaro hwekuita

Iyo Mohs kuoma kwesilicon carbide ceramicsinosvika 9.2, yechipiri chete kudhaimondi, uye kusimba kwayo kwekutsemuka kukapetwa katatu kupfuura kwealuminium ceramics. Ichi covalent crystal chimiro chinopa zvinhu zvakanakisa abrasion kuramba, uye pasi pesimba repamusoro-kumhanya slurry ine gypsum makristasi (kuyerera kusvika ku12m / s), iyo yekupfeka kwepamusoro ingori 1/20 yeiyo yesimbi nozzles. Muacid-base alternating environment ine pH value ye4-10, corrosion resistance rate yesilicon carbide iri pasi pe 0.01mm/gore, iri nani kudarika 0.5mm/gore re316L simbi isina tsvina.

Iyo yekupisa yekuwedzera coefficient yechinhu (4.0 × 10 ⁻⁶/℃) iri padyo neiyo yesimbi, uye inogona kuramba ichichengetedza kugadzikana kwechimiro pasi pekusiyana kwekushisa kwe150 ℃. Silicon carbide ceramics yakagadzirirwa nekuita sintering process ine density inopfuura 98% uye porosity isingasviki 0.5%, zvinobudirira kudzivirira kukuvadzwa kwechimiro kunokonzerwa nepakati kupinza.

2, Precision atomization mechanism uye kuyerera kwemunda wekutonga

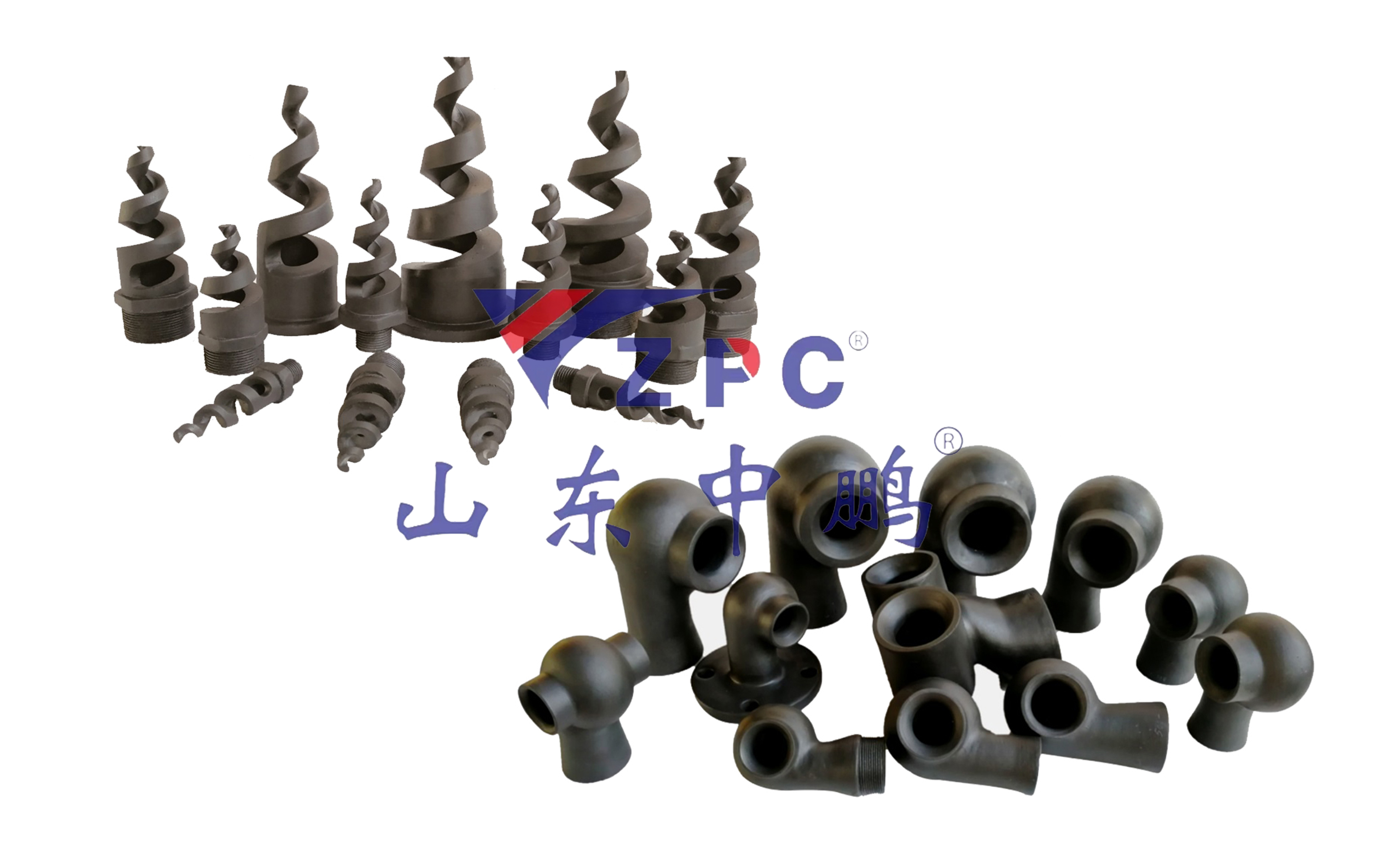

Thesilicon carbide spiral nozzlezvakanyanya kuwedzera kumhanya kwekutenderera kweslurry, uye nekunyatsobuda kunze, inopwanya slurry yeraimestone kuita madonhwe madiki uye akafanana. Iyo hollow conical spray munda yekuvhara mwero wakaumbwa neichi chimiro chakakura kwazvo, uye nguva yekugara yemadonhwe mushongwe inowedzerwa kusvika 2-3 masekondi, 40% yakakwirira kupfuura iyo yechinyakare nozzles.

3, Sistimu yekufananidza uye injiniya optimization

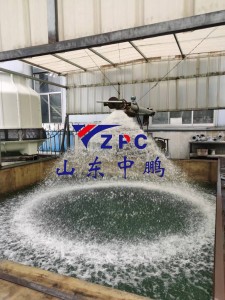

Mune yakajairika spray tower,silicon carbide FGD nozzlesyakarongwa nenzira ye chessboard inoshandiswa, ine spacing ye 1.2-1.5 nguva yespray cone dhayamita, ichiita 3-5 zvidimbu zvekufukidzira. Urongwa uhwu hunovimbisa kuti muchinjika-chikamu kufukidzwa kweiyo desulfurization tower inodarika 200%, kuve nechokwadi chekubatana kwakakwana pakati peflue gasi uye slurry. Iine isina chinhu shongwe yekuyerera mwero we3-5 m / s, iyo system yekumanikidza kurasikirwa inodzorwa mukati meiyo 800-1200 Pa.

Dhiyabhorosi data inoratidza kuti desulfurization inoshanda yeFGD system inoshandisa silicon carbide nozzles inoramba yakagadzikana pamusoro pe97.5%, uye hunyoro hwegypsum by-products hwakaderedzwa kusvika pasi pe10%. Iko kutenderera kwemidziyo yakawedzerwa kubva kumwedzi mitatu yesimbi nozzles kusvika kumakore matatu, uye mutengo wekutsiva maspare parts wakadzikira ne70%.

Kushandiswa kweizviFGD nozzleinoratidza kusvetuka kubva kune yakakura kusvika kune chaiyo yekudzivirira nharaunda. Nekukura kweiyo 3D yekudhinda ceramic tekinoroji, topology optimization dhizaini yekuyerera chiteshi chimiro inogona kuitika mune ramangwana, iyo inogona kuwedzera kuvandudza atomization ne15-20% uye kukurudzira yekupedzisira-yakaderera emission tekinoroji yekupinda nhanho nyowani yebudiriro.

Nguva yekutumira: Mar-24-2025