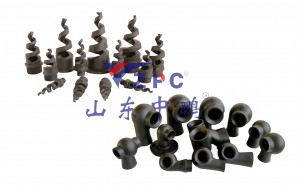

1. Tete'e atu i le 'Ele

Nozzles FGDe fa'agaoioia i siosiomaga e matuā 'ele'elea o lo'o i ai le sulfur oxides, chlorides, ma isi vaila'au malolosi. O le silicon carbide (SiC) ceramic e fa'aalia ai le tete'e atu i le 'ele'elea e itiiti ifo i le 0.1% le pa'u o le mamafa i vaifofo pH 1-14 (e tusa ai ma le su'ega ASTM C863). Pe a fa'atusatusa i le u'amea e le gaoia (PREN 18-25) ma le nickel alloys (PREN 30-40), e tausia e le SiC le tulaga lelei o le fausaga e aunoa ma le pitting po'o le stress corrosion cracking e o'o lava i acids fa'apitoa i le vevela maualuga.

2. Mausali i le Vevela Maualuga

O le vevela o le fa'agaioiga i totonu o faiga fa'amama kasa susu e masani ona i le va o le 60-80°C ma o mea e fa'aoso ai e sili atu i le 120°C. O le keramika SiC e taofia le 85% o lona malosi i le vevela o le potu i le 1400°C, e sili atu nai lo keramika alumina (e leiloa le 50% le malosi i le 1000°C) ma u'amea e tete'e atu i le vevela. O lona fa'avevela (120 W/m·K) e mafai ai ona fa'asalalauina lelei le vevela, ma puipuia ai le fa'aputuina o le atuatuvale i le vevela.

3. Tete'e i le Ofu

Faatasi ai ma le malosi o Vickers e 28 GPa ma le malosi o le gau o le 4.6 MPa·m¹/², o le SiC e faaalia ai le tete'e sili atu i le soloia o le eleele e faasaga i vaega o le lefulefu lele (Mohs 5-7). O su'ega i le fanua e faaalia ai o nozzles SiC e tumau pea le lelava i le <5% pe a uma le 20,000 itula tautua, pe a faatusatusa i le 30-40% o le lelava i nozzles alumina ma le faaletonu atoa o metala ua ufiufi i le polymer i totonu o le 8,000 itula.

4. Uiga o le Tafe

O le fogāeleele e lē susu o le SiC e pipii i le tali (tulimanu fa'afeso'ota'i >100°) e mafai ai ona sa'o le fa'asalalauina o le slurry ma tau CV e <5%. O lona fogāeleele e matuā lamolemole (Ra 0.2-0.4μm) e fa'aitiitia ai le pa'ū o le mamafa i le 15-20% pe a fa'atusatusa i nozzles u'amea, a'o fa'atumauina pea le mautu o le fa'asa'olotoina o le vai (±1%) i le fa'agaoioiga umi.

5. Faigofie o le Tausiga

O le malosi o vailaʻau a le SiC e mafai ai ona faʻamamāina malosi ni auala e aofia ai:

- Vai e tafe ai le mamafa maualuga (e oo atu i le 250 pa)

- Fa'amamāina o le ultrasonic i vaila'au alkaline

- Fa'amamāina i le ausa i le 150°C

E aunoa ma le lamatiaga o le faaleagaina o le fogaeleele e masani ona iai i totonu o paipa u'amea ua ufi pe ufiufi i le polymer.

6. Tamaoaiga o le Taamilosaga o le Olaga

E ui o tau muamua mo SiC nozzles e 2-3× maualuga atu nai lo le u'amea e le gaoia masani 316L, o lo latou umi e fa'aaogaina ai mo le 8-10 tausaga (e fa'atusatusa i le 2-3 tausaga mo u'amea) e fa'aitiitia ai le tele o le suiina i le 70%. O le aofa'i o tau o le umiaina e fa'aalia ai le 40-60% o sefega i vaitaimi e 10 tausaga, fa'atasi ai ma le leai o se taimi e taofia ai galuega toe fa'aleleia i totonu o le nofoaga.

7. Fegalegaleaiga ma le Siosiomaga

Ua faʻaalia e le SiC le faʻatinoga e le mafaatusalia i tulaga faigata:

- Tete'e i le suāsusu masima: 0% suiga o le mamafa pe a uma le 5000 itula su'ega ASTM B117

- Fa'agaioiga o le sau o le 'āsi: Tete'e atu i le ausa H2SO4 i le 160°C

- Tete'e atu i le te'i vevela: E tumau i le 1000°C→25°C taamilosaga o le tineia

8. Meatotino e Tete'e ai i le Fa'ateleina o le Scale

O le fausaga fa'a-atomika covalent o le SiC e fausia ai se luga e le tali atu i gaioiga ma le fua fa'atatau o le fa'asolosolo e 80% maualalo ifo nai lo isi u'amea. O su'esu'ega fa'a-kristalographic e fa'aalia ai o le calcite ma le gypsum deposits e fausia ai ni fusi vaivai (pipii <1 MPa) i luga o le SiC e fa'atusatusa i le >5 MPa i luga o u'amea, ma faigofie ai ona aveese fa'amekanika.

Fa'ai'uga Fa'apitoa

O le seramika silicon carbide ua tulaʻi mai o le filifiliga sili ona lelei mo mea e faʻaaogaina ai le FGD nozzles e ala i le iloiloga atoatoa o le faʻatinoga:

- E 10× le umi o le ola tautua nai lo isi u'amea

- 92% fa'aitiitia i tausiga e le'i fuafuaina

- 35% le fa'aleleia atili o le lelei o le ave'esea o le SO2 e ala i mamanu fa'asusu faifai pea

- Usita'ia atoatoa tulaga fa'atonuina o le EPA 40 CFR Vaega 63 o le kasa fa'asao

Faatasi ai ma le alualu i luma o metotia gaosiga e pei o le liquid-phase sintering ma le CVD coating, o le isi augatupulaga o SiC nozzles ua ausia ai ni fa'auma o luga e itiiti ifo i le micron ma ni foliga faigata e le'i mafai ona ausia muamua i keramika. O lenei alualu i luma fa'atekonolosi ua tu'uina ai le silicon carbide o le mea e filifilia mo faiga fa'amama kesi o le isi augatupulaga.

Taimi na lafoina ai: Mati-20-2025