taila paipa seramika e tete'e i le ofuina - taila silicon carbide ma taila alumina

O le reaction bonded silicon carbide (SiSiC po'o le RBSIC) o se mea lelei e tete'e atu ai i le ofuina, lea e

aemaise lava le talafeagai mo le malosi o le olo, o vaega mafiafia, fa'avasegaga, fa'aputuga, fa'amago ma le

isi galuega. E fa'aaogaina lautele i le alamanuia o le eliina o minerale, alamanuia o u'amea, alamanuia o le fa'agasologa o 'amu, vaila'au

alamanuia, alamanuia o mea mata, faamaufaailoga fa'amekanika, togafitiga oneone ma ata fa'ata'ita'i ma isi.

Fa'afetai i le ma'a'a lelei ma le tete'e atu i le a'afiaga, e mafai ona puipuia lelei le vaega e mana'omia ona ofuina

puipuiga, ina ia faʻateleina ai le umi e faʻaaoga ai le masini.

E sili atu le umi o le ola tautua o keramika SiC nai lo le 92% keramika alumina.

E fa'apefea ona iloa ma maua ni ipu, ta'i, ma ni ufi e tete'e atu i le ofuina o le silicon carbide e maualuga le lelei?

O ta'ele, liners, ma paipa e tete'e atu i le silicone carbide ua fa'ateleina ona fa'aaogaina i le pisinisi o le eliina o minerale.

O manatu nei e mo lau fa'asinomaga:

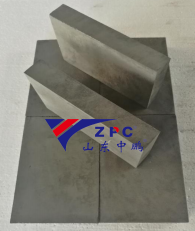

1. Fua fa'atatau ma le faiga:

E tele fa'asologa SiC o lo'o i luga o le maketi. Matou te fa'aogaina fa'asologa moni a Siamani. I su'ega maualuluga i fale su'esu'e, o la matou oloa Erosion ㎝³ loss e mafai ona o'o atu i le 0.85 ± 0.01;

2. Faigata:

O taila SiC e gaosia i le ZPC: malosi fou o le Mohs: 14.55 ± 4.5 (MOR, psi)

3. Mafiafia:

O le mafiafia o le ta'ele ZPC SiC e tusa ma le 3.03+0.05.

4. Tele ma le Laueleele:

O ta'i SiC o lo'o gaosia i le ZPC e aunoa ma ni māvaevae ma ni pu, fa'atasi ai ma ni mea mafolafola ma ni pito ma tulimanu e le'i afaina.

5. Meafaitino i totonu:

O laina/taili e tete'e atu i le ofuina i le silicone carbide e lelei ma tutusa mea i totonu ma fafo.

If any questions, please feel free to contact us: info@rbsic-sisic.com

■Fa'amatalaga:

| Mea | Iunite | Fa'amaumauga |

| Vevela o le fa'aoga | ℃ | 1380℃ |

| Mafiafia | G/cm3 | >3.02 |

| Porosity tatala | % | <0.1 |

| Malosiaga o le punou -A | Mpa | 250 (20℃) |

| Malosiaga o le punou -B | MPa | 280 (1200℃) |

| Modulus o le elasticity-A | GPa | 330(20℃) |

| Modulus o le elasticity -B | GPa | 300 (1200℃) |

| Fa'avevela o le eletise | W/mk | 45 (1200℃) |

| Fa'atusatusaga o le fa'alauteleina o le vevela | K-1 ×10-6 | 4.5 |

| Ma'a'a | / | 13 |

| Alkali e tete'e i le 'āseta | / | sili ona lelei |

■Foliga ma lapopo'a e maua:

Mafiafia: mai le 6mm e oo atu i le 25mm

Foliga Masani: Ipu SISIC, Paipa SISIC, So'otaga SiSiC e Tolu, Tulilima SISIC, Afa o le SISIC Cone.

Fa'amatalaga: O isi lapopo'a ma foliga e maua pe a talosagaina.

■Afifiina:

I totonu o se pusa katuni, fa'aputuina i se pallet laupapa ua fa'asu'iina ma le mamafa mama 20-24MT/20'FCL.

■Fa'amanuiaga autū:

1. Tete'e lelei i le ofuina, tete'e i a'afiaga ma tete'e i le 'ele;

2. Lelei tele le lamolemole ma le tete'e lelei i le vevela e o'o atu i le 1350 ℃

3. Fa'apipi'i faigofie;

4. O le umi o le ola tautua (e tusa ma le 7 taimi e sili atu nai lo le alumina ceramic ma le 10 taimi e sili atu nai lo le

polyurethane

Fa'ata'ita'iga o le oloina o le tulimanu oloina o le tulimanu maualalo

A pa'ū le tafe o le mea fa'a'ole'ole i se mea e ofi ai i se tulimanu papa'u pe pasia fa'atasi ma lea mea, o le ituaiga o ofi e tupu i le fete'ena'iga e ta'ua o le sliding abrasion.

O keramika silicon carbide fa'aonaponei e maua ai le tete'e atu i le ofuina ma le tete'e atu i le 'ele'ele o ta'i ma le laina. O nei oloa ua fa'amaonia le ofuina o masini i le felauaiga, fa'agasologa, ma le teuina. E mafai ona gaosia a matou ta'i ma le mafiafia mai le 8 i le 45mm. e taua le fa'amautinoa e mafai ona e mauaina oloa mana'omia. SiSiC: O le malosi o le Moh e 9.5 (o le malosi fou o le Moh e 13), fa'atasi ai ma le tete'e lelei i le solo ma le 'ele'ele, tete'e lelei i le olo ma le tete'e atu i le 'oxygenation'. E 4 i le 5 taimi e sili atu le malosi nai lo le nitride bonded silicon carbide. O le umi o le tautua e 5 i le 7 taimi e sili atu nai lo le mea alumina. O le MOR o le RBSiC e 5 i le 7 taimi nai lo le SNBSC, e mafai ona fa'aaogaina mo foliga e sili atu ona faigata. O le laina seramika e tete'e atu i le ofuina e fa'aleleia atili ai le fa'atinoga o le gaosiga, le lelei o le galue, le fa'aitiitia o tau o le tausiga ma le fa'ateleina o tupe mama.

O keramika sa'o e iai le malamalama i meafaitino, tomai fa'apitoa ma tomai fa'ainisinia. E mafai ona fa'amautinoa lelei ai o lo'o ofoina atu fofo sili ona lelei i a matou tagata fa'atau. O ta'ele seramika silicon carbide ma le laina e masani ona fa'aaogaina i galuega e pei o afa, paipa, alavai, hoppers, paipa, fusipa'u conveyor ma faiga gaosiga. I totonu o le faiga, e iai mea fe'avea'i o lo'o se'e i luga. A se'e le mea i luga o se meafaitino, e fa'agesegese ona fa'a'ele'elea vaega se'ia o'o ina leai se mea e totoe. I siosiomaga e tele ai le ofuina, e mafai ona tupu soo lenei mea ma mafua ai le tele o fa'afitauli taugata. O le fausaga autu e taofia e ala i le fa'aaogaina o se mea e matua'i ma'a'a, e pei o keramika silicon carbide ma keramika alumina e fai ma laina e fai ma taulaga. I le taimi lava e tasi, e mafai e keramika silicon carbide ona tumau i le ofuina mo se taimi umi a'o le'i mana'omia ona sui, o le umi o le tautua o le keramika silicon carbide e 5 i le 7 taimi le umi nai lo le mea alumina.

O Ta'ele Seramika Silicon Carbide e Tete'e i le Ofu ma Meatotino o le Lining:

Tete'e i vaila'au fa'akemikolo

E taofia ai le eletise

Tetee i le soloia fa'amekanika ma le soloina

E mafai ona sui

Fa'amanuiaga o le Ceramic Wearproof Wear Tiles & Linings:

E mafai ona fa'aaogaina pe a mana'omia ni fa'apalepale vaapiapi pe ni laina manifinifi

E mafai ona faʻaaogaina e toe faʻaleleia ai vaega ua leva ona faigofie ona ofuina

E mafai ona faʻaaogaina i le tele o auala e faʻapipiʻi ai e pei o le faʻavevela ma mea faʻapipiʻi

Fuafuaina faapitoa mo ni faʻaoga faapitoa

E tete'e tele i le 'ele

Fofo mama e fa'aitiitia ai le ofuina

Puipuia vaega fe'avea'i e faigofie ona o'o i siosiomaga e tele ai le ofuina

E sili atu le umi ma sili atu ona lelei nai lo fofo e faʻaitiitia ai le ofuina

Vevela maualuga tele e oo atu i le 1380°C

1, Falegaosimea u'amea ma u'amea: 1, laina o le masini fa'afefiloi o le talipalau 2, pa'u seramika ua afifi i le talipalau 3, impeller ili 4, fafaga tisiketi, auala e fa'amamago ai mea mago 5, fa'aputuga coke, pusa fa'aliliu, pusa coke, ma le aoina o le pefu afa.

2, Falegaosimea eletise: 1. Pusa e alu ese ai le falegaosimea polo, volute o le falegaosimea, pusa e alu ese ai le falegaosimea saoasaoa feololo, tulilima paipa pauta, mea e aoina ai le pefu o le afa, silo, hopper 2, hopper malala, vavaeese ai le pauta mafiafia ma lelei, pusa e alu ese ai le falegaosimea malala, hopper e feaveaʻi ai le malala 3, hopper malala o le puʻeina o le alalaupapa, hopper malala tutotonu o le masini eli malala, pusa e alu ese ai le falegaosimea polo, faitotoʻa e ulufale ai ma fafo o le vavaeese ai le pauta mafiafia ma lelei, volute o le mea e faʻamamā ai le pauta 4. O ituaiga eseese o afi e teteʻe atu i le vevela saʻo, mafiafia ma faʻafefeteina mo le vevela maualuga mo paila e faʻamumuina i le malala; paipa ma tulilima tuʻufaʻatasi seramika e teteʻe atu i le ofuina, afi seramika, ili seramika, impellers seramika, valve seramika, ma isi; vaega eseese e teteʻe atu i le ofuina e pei o polo olo, lima faʻaseʻe, tisiketi olo, taʻi tisiketi, mama olo, polo nozzle ma isi vaega e teteʻe atu i le ofuina mo falegaosimea malala saoasaoa feololo; paipa, damper e teteʻe atu i le ofuina ma ili o faʻamatalaga eseese mo faiga e pulverizing ma aveese ai le lefulefu; Polo O ituaiga uma o olo e iai (pe leai) le poloka o le laina o le polo, le laupapa laina, le paipa faataamilo, le mama o le kia, le polo uʻamea uʻamea maualalo le chromium, ma isi mea faapena; uili taia, laupapa taia, matau puipui, ofutau, vavaeese, paipa kesi o le ogaumu vevela maualuga, ma isi mea faapena mo le olo malala ili; mea faaopoopo e manaomia mo ituaiga eseese o masini olo.

3, Fale gaosi pepa: 1. Paipa malala ua palu

Oloa ma auaunaga autū: 1. Paipa seramika e tete'e i le ofuina i pisinisi: ituaiga uma o seramika e tete'e i le ofuina ma le vevela maualuga ua laina i le malala ua palu, otaota, otaota palapala, paipa felauaiga otaota, tulilima, tulilima, ogaumu malala ua palu, auala e alu ese ai le fale gaosi malala, vavae'ese o le afa o le pauta mafiafia ma le pa'u manifinifi, chute, hopper, pusa teuina, paelo fa'amama o le maina; 2. Ili seramika e tete'e i le ofuina: ituaiga uma o impeller ma volute e tete'e i le vevela maualuga, tete'e i le ofuina, e tete'e i le pala o le ili, e aofia ai le centrifugal fan, axial flow fan, static blade, movable blade adjustable fan impeller, suction fan, powder exhauster, sintering fan, powder desemination fan, ili e aveese ai le pefu, kiln head ma kiln tail fan, ma isi; 3. Pamu ma valve laina seramika e tete'e i le ofuina: laina seramika, pamu impeller, atigi, baffle, paipa tulilima, pneumatic lefulefu aveese ma le kesi ma mea fa'aopoopo o le tele o slurry, otaota palapala, sima, otaota ma isi faiga felauaiga. 4. Ufiufi seramika e tete'e i le ofuina: o ituaiga uma o ufiufi seramika e tete'e i le ofuina ma le vevela maualuga ma le mastic e fa'aaogaina mo le volute fan, paipa kilima, auala e alu ese ai le mill, paipa vavae mafiafia ma manifinifi, chute, hopper ma valve. 5. Meafaigaluega vavae maneta e tete'e i le ofuina: vaega e alu ai le tafe o le tele o masini fa'agasolo minerale mago ma susu, e aofia ai le magnetic separator drum, pito i lalo, chute, paipa, pamu palapala eseese, slurry pump volute, impeller, ma paipa felauaiga. 6. Tekinolosi fa'asusu luga: fa'aaogaina le sapalai eletise fa'avaomalo fou o le inverter pulse arc ma le fana fa'asusu arc saoasaoa maualuga, o le tele o mea u'amea e tete'e i le ofuina ma le tete'e i le 'ele'ele e fa'asusu i luga o le u'amea e fausia ai se vaega puipui e tete'e i le ofuina ma le tete'e i le 'ele'ele. E mafai ona tu'uina atu le puipuiga lelei mo ituaiga uma o le 'ele'ele malosi feololo.

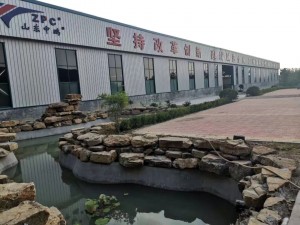

O le Shandong Zhongpeng ZPC ceramics o se pisinisi e fa'apitoa i le gaosiga o keramika fa'apisinisi, e tele lava ina fa'atinoina le R & D ma le gaosiga o keramika silicon carbide. E mafai ona matou fa'agasoloina oloa keramika e tusa ai ma au ata tusi, fa'apitoa i le gaosiga o la'au keramika tetele ma sa'o, paipa keramika, mama keramika, ipu keramika, flange keramika, nozzle keramika, ma vaega tetele fa'apitoa e tete'e i le ofuina.

O le Shandong Zhongpeng Special Ceramics Co., Ltd o se tasi o fofo sili ona tele mo mea fou o le silicon carbide ceramic i Saina. SiC technical ceramics: O le malosi o le Moh e 9 (o le malosi o le Moh fou e 13), faatasi ai ma le tete'e lelei i le solo ma le ele, tete'e lelei i le olo ma le tete'e i le okesene. O le umi o le tautua a le oloa SiC e 4 i le 5 taimi e umi atu nai lo le 92% o le alumina. O le MOR o le RBSiC e 5 i le 7 taimi nai lo le SNBSC, e mafai ona fa'aaogaina mo foliga e sili atu ona faigata. O le faiga o le tauofoga e vave, o le tu'uina atu e pei ona folafolaina ma o le lelei e le mafaatusalia. Matou te tumau pea i le lu'itauina o a matou sini ma toe avatu o matou loto i le sosaiete.