SiC Crucibles and Saggers manufacturer/factory – SiC Sagger for Powder Sintering

SiC Sagger for Powder Sintering

RBSIC/SISIC crucible is a deep bowl of ceramic containers. Because of its better performance than glassware at the heat resistance, It is well used when solids are heated by fire.

Sagger is made of refractory mud of various specifications of the mortar, baked at high temperature. It is one of the important kiln furniture for burning porcelain. All kinds of porcelains must be put into saggers first and then into the kiln for roasting.

SPECIFICATION:

| Index | RSiC | NSiC | RBSiC | SiC |

| Bulk density(g/cm3) | 2.65-2.75 | 2.75-2.85 | ≥3.02 | 2.8 |

| SiC(%) | ≥99 | ≥75 | 83.66 | 90 |

| Si3N4(%) | 0 | ≥23 | 0 | 0 |

| Si(%) | 0 | 0 | 15.65 | 9 |

| Porosity(%) | 15-18 | 10-12 | 0.1 | 7-8 |

| Bending strength(MPa) | 80-100(20℃) | 160-180(20℃) | 250(20℃) | 500(20℃) |

| Bending strength(MPa) | 90-110(1200℃) | 170-180(1200℃) | 280(1200℃) | 550(1200℃) |

| Bending strength(MPa) | 90-120(1350℃) | 170-190(1350℃) | - | - |

| Modulus of elasticity(GPa) | 300(20℃) | 580(20℃) | 330(20℃) | 200 |

| Modulus of elasticity(GPa) | - | - | 300(1200℃) | - |

| Thermal conductivity(w.m-1.k-1) | 36.6(1200℃) | 19.6(1200℃) | 45(1200℃) | 13.5-14.5(1000℃) |

| Coefficient of thermal expansion(K-1×10-6) | 4.69 | 4.7 | 4.5 | 3 |

| Rigidity | - | - | 13 | - |

| Max working temperature(℃) | 1620(oxid) | 1450 | 1380 | 1300 |

FACTORY:

About Us:

We are a company specializing in the production of RBSIC/SISIC Silicon Infiltrated Silicon Carbide Products.

- Professional Production Process

- Imported High Quality Raw Materials

- Complete Production Managing System

CATALOGUE:

Advantages:

- High strength and extreme hardness

- High temperature resistance and excellent thermal shock resistance

- Excellent bearing capacity

- Resistance to extreme heat and cold.

- High temperature creep resistance

- Corrosion resistance and Oxidation resistance

- Acid and alkali resistance

- Wear resistance& good thermal conductivity

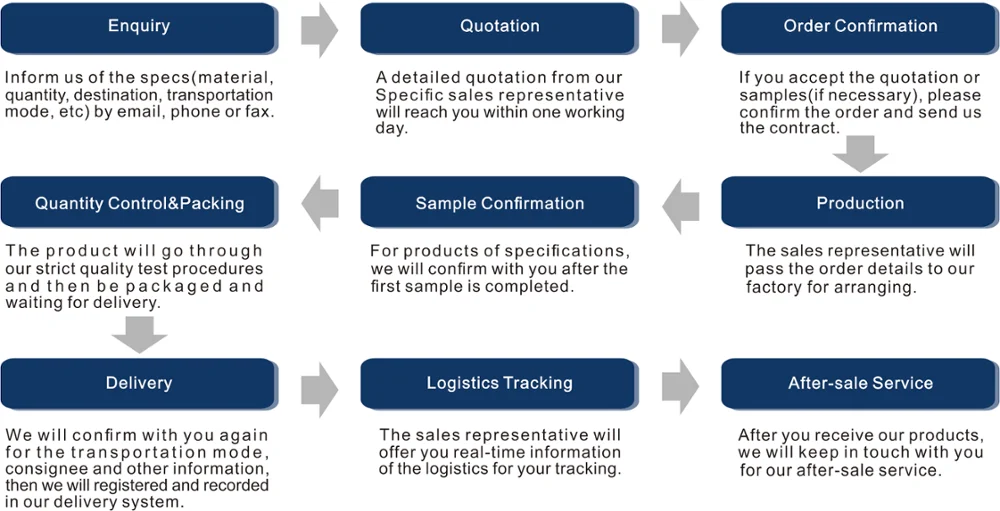

ORDER PROCESS:

PRODUCTION PROCESS:

The silicon carbide ceramics crucibles and saggers can be used for various powder sintering, metal smelting, etc. in the fields of metallurgy, chemical industry, glass and the like. Shandong Zhongpeng is committed to research and development, production and sales of high-performance silicon carbide products, the main products are reaction sintered silicon carbide ceramic beams, roller bars, fire nozzles, cold air ducts, sheds, enamel, enamel, thermocouple protection Tube, heat exchange tube, radiant tube inner tube, radiant tube outer tube, desulfurization nozzle, cantilever paddle, atmosphere furnace tube, sand blasting nozzle, bushing, seal and various high temperature, wear and corrosion resistant silicon carbide ceramic shaped Piece, etc., reaction sintered silicon carbide ceramic products with high strength, high hardness, wear resistance, high temperature resistance, corrosion resistance, oxidation resistance, thermal shock resistance and thermal conductivity, resistance to quenching and rapid heat and high temperature creep resistance , is widely used in military, aerospace, nuclear power, liquid crystal and metallurgy, chemical, machinery, automotive, paper, medicine and other fields, products are exported to the United States, Germany, Japan, South Korea, United Arab Emirates, South Africa, Taiwan and other more than 40 countries and area.

Reaction bonded silicon carbide (SiSiC): Moh’s hardness is 9.5, with excellent resistance to erosion and corrosion, excellent abrasion-resistance and anti-oxidation. It is 4 to 5 times stronger than nitride bonded silicon carbide. The service life is 7 to 10 times longer than alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes.

PACKAGING:

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.