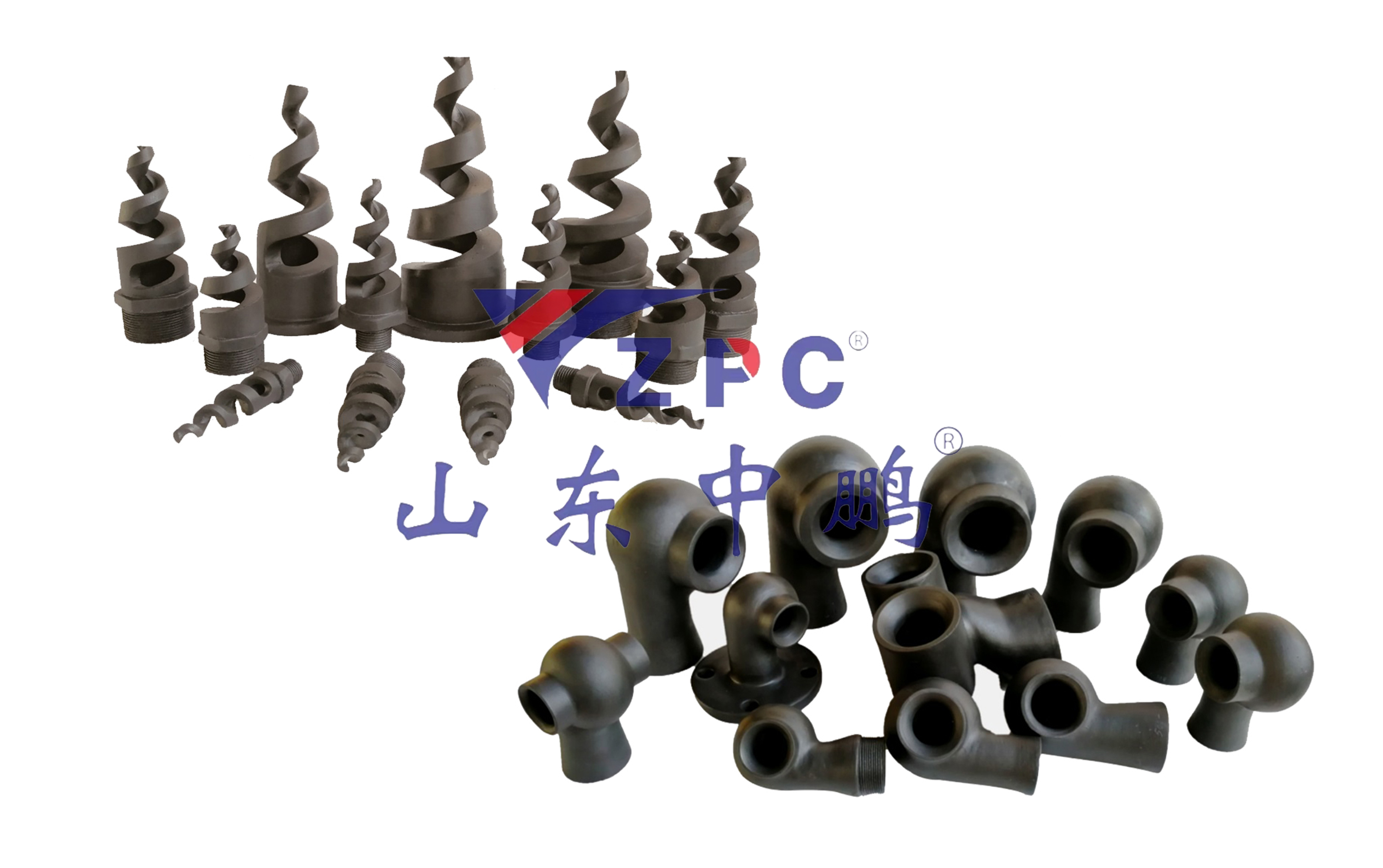

Silicon carbide Flue Gas Desulphurization Spray nozzle

When it comes to flue gas desulphurization (FGD), reliability and durability are non-negotiable. Our silicon carbide (SiC) spiral spray nozzles redefine industry standards by combining cutting-edge material science with innovative design, delivering solutions that outperform conventional alternatives in the most demanding applications.

Key Advantages

1. Unrivaled Resistance to Extreme Conditions

Crafted from premium silicon carbide, these nozzles thrive in aggressive environments where other materials fail. They effortlessly withstand corrosive chemicals, abrasive slurries, and rapid thermal cycling, ensuring consistent performance even in systems handling high-chloride flue gases or fluctuating temperatures.

2. Precision Spray Patterns for Optimal Efficiency

The advanced spiral design generates finely tuned droplet dispersion, maximizing gas-liquid contact while minimizing liquid waste.This intelligent engineering translates to superior SO₂absorption rates and reduced reagent consumption, directly lowering operational costs.

3. Maintenance-Free Longevity

Unlike metal or polymer alternatives, our SiC nozzles resist scaling, clogging, and erosion.Their non-wetting surface prevents particle buildup, guaranteeing stable flow rates and spray angles over years of continuous operation—no downtime for replacements or cleaning.

4. Adaptability Across Industries

Whether deployed in coal-fired power plants, waste incinerators, or marine scrubbers, these nozzles maintain peak performance.Their universal compatibility spans traditional limestone scrubbing systems to emerging seawater FGD configurations.

5.Sustainability by Design

By eliminating premature replacements and optimizing chemical usage, our nozzles support greener operations.Their corrosion-proof construction ensures zero heavy metal leaching, aligning with strict environmental regulations and circular economy principles.

Why Choose Our Solution?

1.Reliability: Built to outlast entire FGD system upgrade cycles.

2.Energy-Smart Operation:Reduced pump pressure requirements lower energy consumption.

3.Plug-and-Play Integration:Retrofit-ready for seamless upgrades of aging FGD systems.

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.