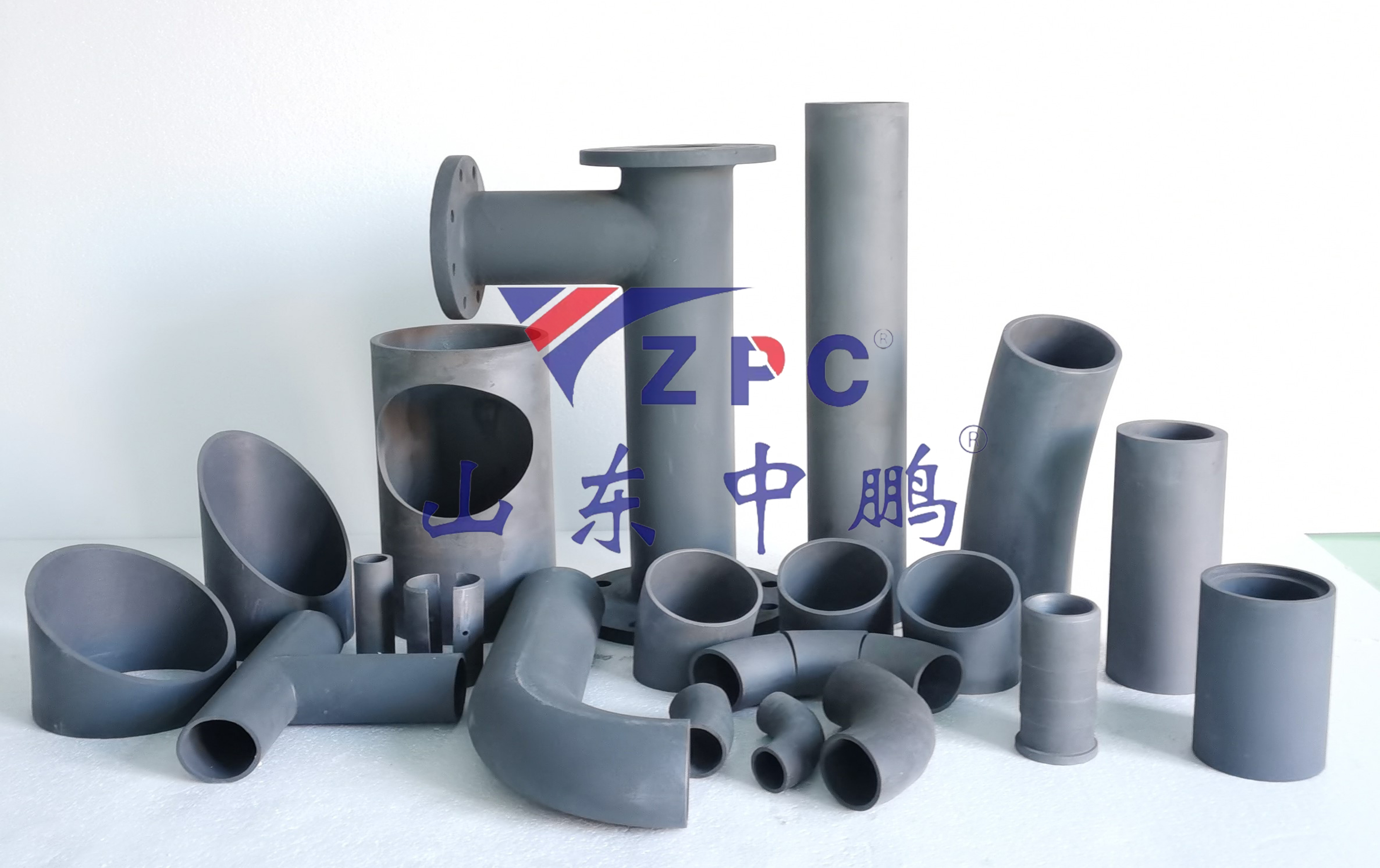

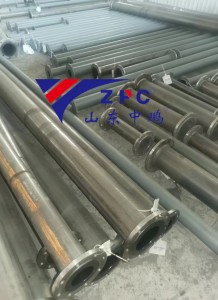

Silicon carbide ceramic lined wear-resistant pipe

Silicon carbide wear-resistant pipes are pipes made mainly of silicon carbide and have wide applications in multiple fields. Its core competitiveness is as follows:

(1)Life Revolution

When transporting abrasive media such as slurry and coal ash, the lifespan is 10 times that of metals, reducing frequent replacement and downtime losses.

(2)Extreme working conditions are universal

Stable operation from -50 ℃ to 1600 ℃, with thermal shock resistance to prevent cracking, suitable for high-temperature scenarios such as metallurgy and chemical industry.

(3)Multiple uses of one material

Simultaneously solve the four major problems of wear, corrosion, high temperature, and explosion prevention.

(4)Lightweight and energy-saving

Lightweight design reduces transportation and installation costs, and low friction coefficient reduces pumping energy consumption.

The crushing advantage of silicon carbide pipes compared to traditional materials:

|

Performance dimension |

Silicon carbide pipeline |

Metal/Plastic pipes |

|

Wear resistance |

Hardness 2800HV (5 times that of steel), lifespan 10 times longer than that of non-metallic pipelines |

Metal is prone to wear and tear, while plastic has low hardness (PE<1 HV) |

|

High temperature resistance |

Resistant to high temperatures of 1600 ℃ and thermal shock (coefficient of thermal expansion 4 × 10 ⁻⁶/℃) |

Stainless steel is prone to oxidation at high temperatures, while plastics have a temperature resistance of less than 80 ℃ |

|

Corrosion resistance |

Resistant to strong acids (concentrated sulfuric acid), strong bases, and molten metal corrosion |

Stainless steel experiences pitting corrosion when exposed to chloride ions, while plastic has limited chemical resistance |

|

Lightweight |

Density of 3.0~3.14 g/cm ³ (60% lighter than steel) |

Metal pipelines are bulky and have high installation costs |

|

Functional Expansion |

Anti static (weak conductivity), semiconductor grade cleanliness |

Metals require additional treatment for explosion prevention, while plastics are prone to contamination |

In short, there is almost no alternative solution for silicon carbide pipelines when transporting highly corrosive and wear-resistant media such as acidic slurries and high-temperature flue gas ash.

If you have any questions, please feel free to contact us at any time.

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.