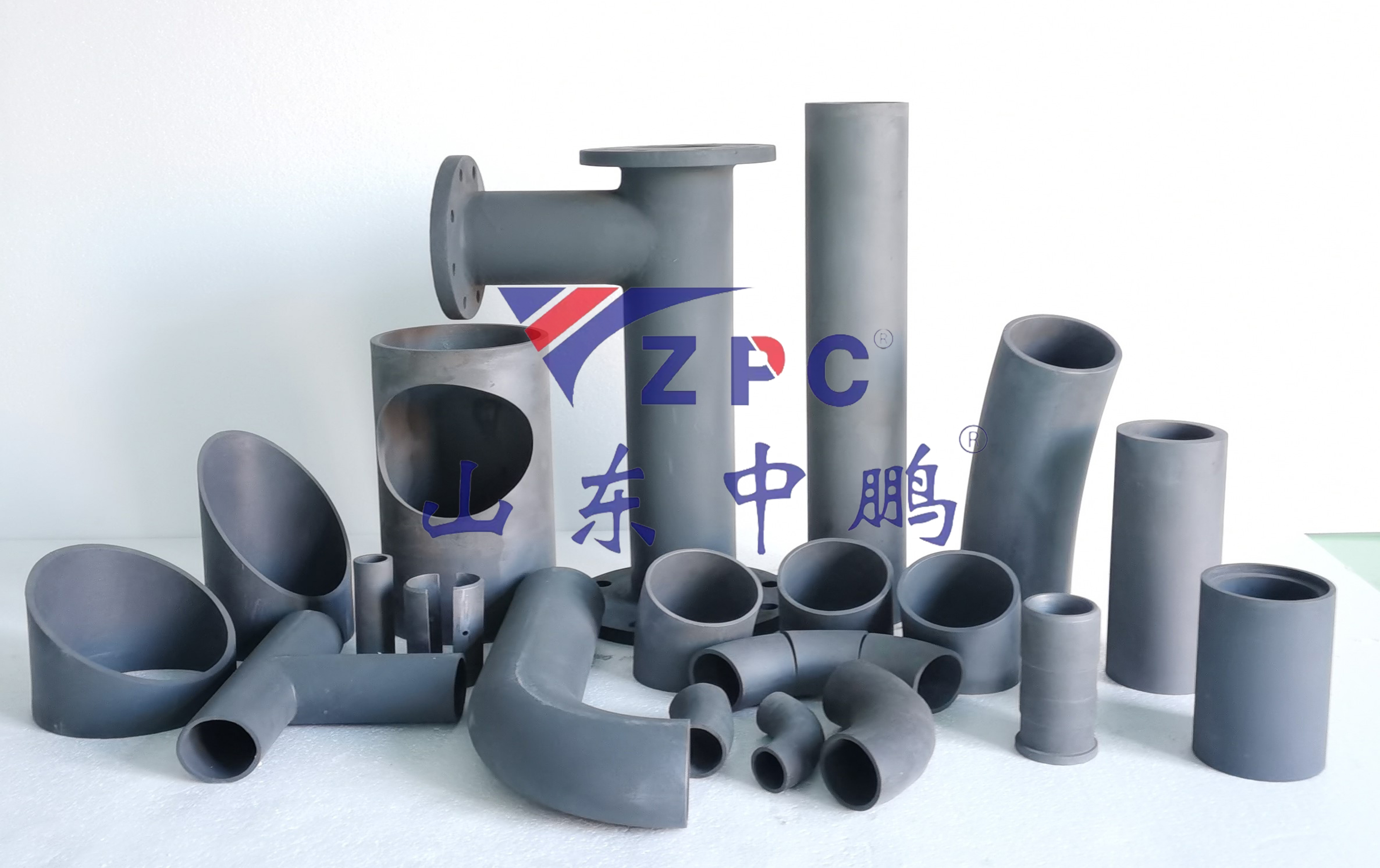

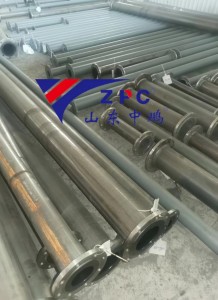

Silicon carbide ceramic lined wear-resistant pipe and hydrocyclone in power plants

Silicon Carbide Ceramic Piping Systems: Reinventing Power Plant Infrastructure

Power generation facilities face extreme operational challenges, with piping systems enduring:

- Continuous thermal cycling (100–650°C)

- Abrasive particle velocities exceeding 30 m/s

- pH variations from 2–12 in flue gas scrubbers

- Cyclic pressure fluctuations (0–6 MPa)

Traditional metallic and polymer pipelines frequently fail under these conditions, making silicon carbide (SiC) ceramic wear-resistant pipes the engineered solution for modern power plants.

Material Science Breakthrough

SiC ceramic pipes combine unique properties essential for energy sector applications:

- Vickers Hardness 28 GPa (4× harder than tungsten carbide)

- Wear Rate <0.1 mm³/N·m (ASTM G65)

- Thermal Conductivity 120 W/m·K (superior to stainless steel)

- Chemical Inertness (resists 98% H₂SO₄ at 300°C)

Operational Advantages in Critical Systems

1. Coal Handling & Ash Transport

- Withstand 5–7 mm/yr erosive wear from 60% solid-content slurry

- Maintain <5% flow reduction over 10,000 operational hours

2. Flue Gas Desulfurization (FGD)

- pH-resistant performance in limestone slurry circuits

- Eliminate chloride-induced pitting corrosion

3. Fly Ash Conveyance

- 0.08 μm surface roughness minimizes particle adhesion

- Handle 50 tph capacity at 35° inclination angles

Economic Transformation

Plant operators report measurable benefits:

- 70% reduction in unplanned pipe replacements

- 55% lower maintenance labor costs

- 18% improved thermal efficiency in steam cycles

- 40% extended system lifespan vs. alloy alternatives

Installation & Operational Flexibility

- Modular 1–6 m sections with flanged/threaded connections

- 60% weight reduction vs. steel equivalents (3.2 g/cm³ density)

- Retrofittable to existing pipe supports and hangers

- Compatible with smart monitoring systems for wear prediction

Future-Focused Innovations

Next-generation SiC piping solutions integrate:

- Gradient porosity for thermal stress mitigation

- Conductive variants for electrostatic precipitation

- Hybrid ceramic-elastomer joints for vibration damping

- Self-cleaning surface nano-textures

From coal-fired plants to waste-to-energy facilities, silicon carbide ceramic pipes redefine reliability in power infrastructure. Their unique combination of mechanical resilience, thermal endurance, and chemical stability ensures continuous operation under extreme conditions – transforming maintenance schedules from reactive repairs to planned, cost-effective upgrades.

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.