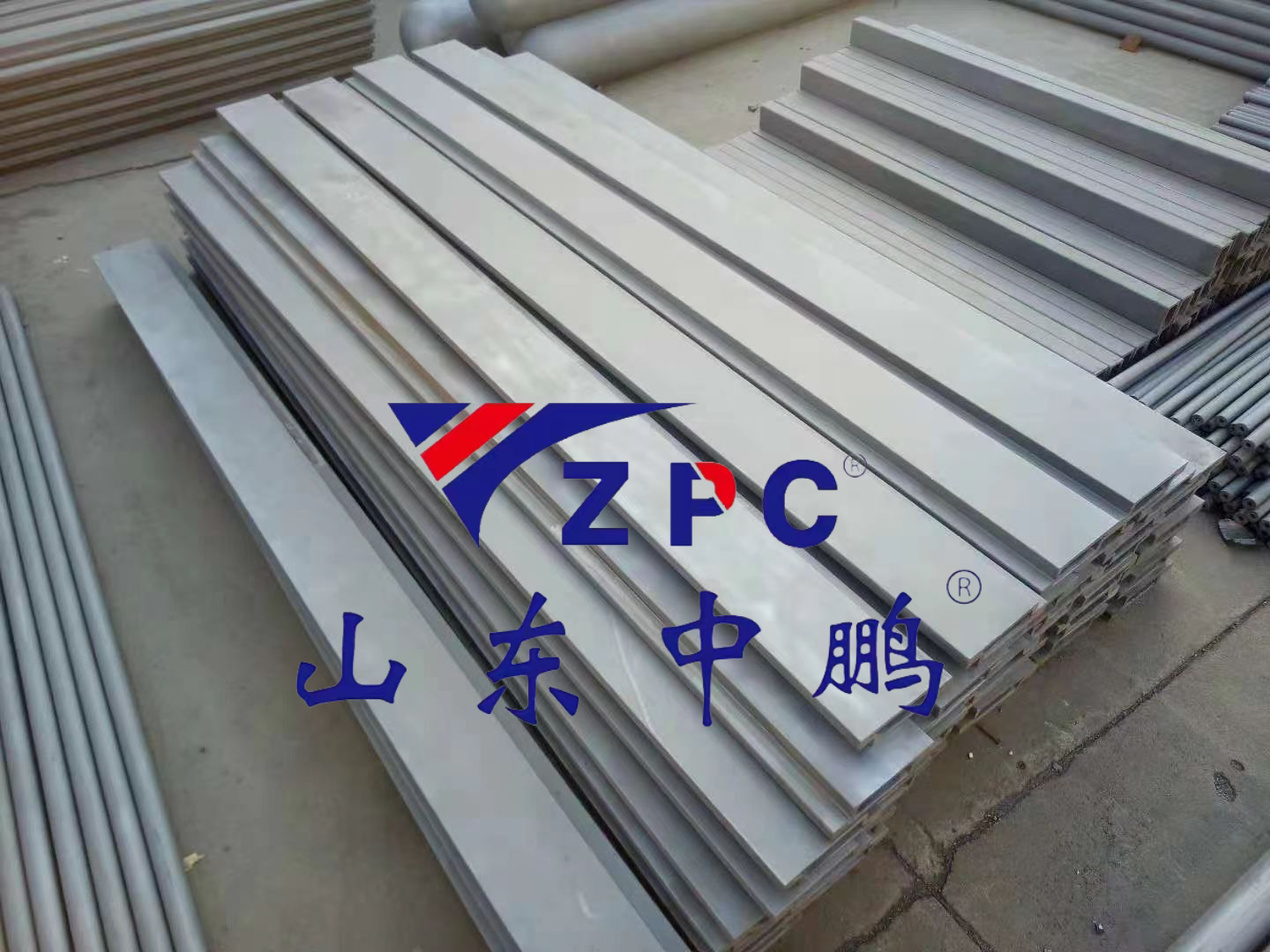

Silicon carbide beams

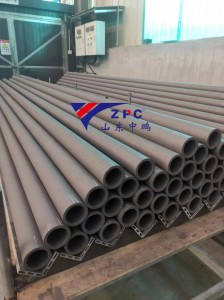

Reaction-sintered silicon carbide (R-SiC) ceramic rollers have emerged as critical components in modern thermal processing systems, particularly excelling in lithium battery manufacturing, advanced ceramics production, and precision magnetic material sintering. These specialized rollers redefine performance standards in high-temperature industrial furnaces by addressing key challenges in thermal stability and mechanical durability.

Unmatched Thermal Performance

Designed to operate continuously at 1450-1600°C – significantly higher than traditional alumina rollers – R-SiC rollers maintain dimensional precision even under extreme thermal cycling. Their unique microstructure enables:

• Rapid heat transfer uniformity (±5°C across roller length)

• Withstanding 100+ thermal shock cycles (1400°C ↔ room temperature)

• Zero creep deformation at sustained high temperatures

Critical Applications Redefined

1. Lithium Battery Production

- Precise alignment for electrode material sintering

- Contamination-free handling of NMC/LFP cathodes

- Stable operation in reducing atmospheres

2. Advanced Ceramics Processing

- Warp-free support for large-format tiles (up to 1.5×3m)

- Consistent speed control in sanitaryware glazing lines

- Non-marking surface finish (Ra <0.8μm)

3. Magnetic Material Manufacturing

- Vibration-free rotation for oriented ferrite sintering

- Chemical inertness in hydrogen-rich environments

Operational Advantages

Load Capacity:Supports 3-5× greater weight per unit length vs. metal alloy rollers

Deformation Resistance: Maintains <0.05mm/m straightness after 10,000 operational hours

Energy Efficiency:18-22% reduced furnace energy consumption through optimized heat distribution

Cross-Industry Compatibility:Adaptable to shuttle kilns, multi-layer roller hearths, and hybrid tunnel furnaces

Economic Sustainability

While requiring 30-40% higher initial investment than conventional rollers, R-SiC solutions demonstrate:

- 70% longer service intervals (5-7 years vs. 2-3 years)

- 90% recyclability through thermal reclamation processes

- 60% lower maintenance costs from abrasion-resistant surfaces

Future-Ready Design

Modern R-SiC rollers now incorporate:

- Laser-engraved tracking grooves for automated production lines

- Customizable porosity for specific atmosphere permeability

- Integrated thermal sensors for smart kiln operations

These technological advancements position reaction-sintered silicon carbide rollers as indispensable components in next-generation industrial heating systems, enabling manufacturers to achieve tighter temperature control, higher product consistency, and sustainable production workflows across multiple high-tech sectors.

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.