Sample of SiC FGD Nozzle,Tangential Swirl FGD Nozzle

Reaction bonded silicon carbide (SiSiC): Moh’s hardness is 9.5, with excellent resistance to erosion and corrosion, excellent abrasion-resistance and anti-oxidation. The same sizes, Iit is 4 to 5 times stronger than nitride bonded silicon carbide. The service life is 7 to 10 times longer than alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. Shandong Zhongpeng Special Ceramics Co., Ltd (ZPC) is the biggest manufacturer of SiSiC FGD nozzles in China. ZPC are the stable supplier of CHINA POWER GROUP, and have extensive cooperation with world ranged customers.

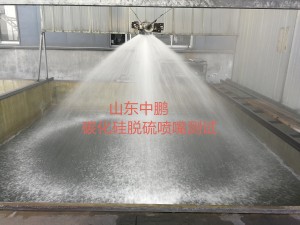

The slurry enters the swirl chamber of the nozzle from the tangential direction. Then, the liquid is ejected from the nozzle hole at right angles to the inlet direction. For Hollow cone vortex nozzle, they are the integrated one in production. Its spray shape is hollow conical whose injection area is circular. The spray angle and flow of Hollow cone vortex nozzle could be designed on the basis of the customers’ requirements. Spray particles of hollow cone vortex nozzle are fine and uniform in diameter. Because of its large vortex channel, the nozzle is not easy to plug. The common vortex nozzles are Hollow cone tangential nozzles, Full cone tangential nozzles, Large free passage double hollow cone tangential nozzles.

Common connection form: winding adhesive flanged connections and threaded connections.

Spray effect: 90°, 120°

Nozzle testing:

Application:

Factory View:

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.