1. Kurwanya ruswa

FGD nozzlesikorera mubidukikije byangirika cyane birimo okiside ya sulfure, chloride, nindi miti ikaze. Carbide ya Silicon (SiC) ceramic yerekana kwihanganira ruswa idasanzwe hamwe nigihombo kiri munsi ya 0.1% mubisubizo bya pH 1-14 (kubizamini bya ASTM C863). Ugereranije nicyuma kitagira umwanda (PREN 18-25) hamwe na nikel alloy (PREN 30-40), SiC igumana ubunyangamugayo bwuburyo butarinze gutobora cyangwa guhangayika kwangirika ndetse no muri acide yibitseho ubushyuhe bwinshi.

2. Ubushyuhe bwo hejuru

Ubushyuhe bukoreshwa muri sisitemu ya gazi ya desulfurizasi isanzwe iri hagati ya 60-80 ° C hamwe na spike irenga 120 ° C. Ceramic ya SiC igumana 85% byimbaraga zicyumba cyayo kuri 1400 ° C, irusha ubukorikori bwa alumina (gutakaza imbaraga za 50% na 1000 ° C) hamwe nicyuma kirwanya ubushyuhe. Ubushyuhe bwacyo (120 W / m · K) butuma ubushyuhe bukwirakwizwa neza, bikarinda kwiyongera k'umuriro.

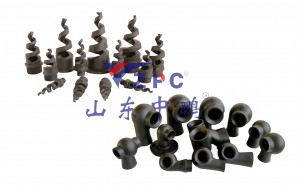

3. Kwambara Kurwanya

Hamwe na Vickers ubukana bwa 28 GPa hamwe no kuvunika kwa 4,6 MPa · m¹ / ², SiC igaragaza isuri irwanya isuri irwanya uduce tw’ivu (Mohs 5-7). Ibizamini byo mu murima byerekana Sizz nozzles ikomeza <5% kwambara nyuma yamasaha 20.000 ya serivisi, ugereranije na 30-40% kwambara muri alumina nozzles no gutsindwa burundu ibyuma byometse kuri polymer mugihe cyamasaha 8000.

4. Ibiranga ibintu

Ubuso butarimo ubushuhe bwa reaction-ihujwe na SiC (guhuza impande> 100 °) ituma itandukanyirizo ryihuse hamwe nagaciro ka CV <5%. Ubuso bwacyo bworoshye cyane (Ra 0.2-0.4μm) bugabanya kugabanuka k'umuvuduko ku gipimo cya 15-20% ugereranije nozle y'icyuma, mugihe gikomeza coefficient zihoraho (± 1%) mugihe kirekire.

5. Kubungabunga Ubworoherane

Imiti ya SiC ituma uburyo bwo gukora isuku burimo:

- Indege y'amazi yumuvuduko mwinshi (kugeza kuri 250 bar)

- Ultrasonic isuku hamwe nibisubizo bya alkaline

- Guhindura amavuta kuri 150 ° C.

Nta ngaruka zo kwangirika kwubusanzwe bikunze kugaragara muri polymer cyangwa umurongo wicyuma.

6. Ubukungu bwubuzima

Mugihe ibiciro byambere kuri SiC nozzles biri hejuru ya 2-3 × hejuru yicyuma gisanzwe 316L cyuma, ubuzima bwabo bwimyaka 8-10 (vs imyaka 2-3 kumyuma) bigabanya inshuro zisimburwa 70%. Ibiciro byose bya nyirubwite byerekana kuzigama 40-60% mugihe cyimyaka 10, hamwe na zeru zigihe cyo gusana aho.

7. Guhuza ibidukikije

SiC yerekana imikorere itagereranywa mubihe bikabije:

- Kurwanya imyunyu yumunyu: 0% ihinduka ryinshi nyuma ya 5000hr ASTM B117

- Gukora ikime cya acide: Ihangane na 160 ° C H2SO4

- Kurwanya ubushyuhe bwumuriro: Kurokoka 1000 ° C → 25 ° C kuzimya

8. Kurwanya Ibipimo

Imiterere ya atome ya covalent ya SiC ikora ubuso budakorwa hamwe nigipimo cyo gupima 80% munsi yicyuma. Ubushakashatsi bwa Crystallographic bugaragaza ko kubitsa calcite na gypsumu bigira imipaka idakomeye (adhesion <1 MPa) kuri SiC na> 5 MPa ku byuma, bigatuma kuvanaho imashini byoroshye.

Umwanzuro wa tekiniki

Silicon carbide ceramic igaragara nkuburyo bwiza bwo guhitamo ibikoresho bya FGD binyuze mumasuzuma yuzuye:

- 10 × igihe kirekire cyumurimo kuruta ibyuma byubundi buryo

- kugabanuka kwa 92% mukubungabunga bidateganijwe

- 35% kunoza uburyo bwo gukuraho SO2 binyuze muburyo bwa spray

- Kubahiriza byuzuye EPA 40 CFR Igice cya 63 ibipimo byangiza

Hamwe nogutezimbere tekiniki yo gukora nka feri-feri yo gucumura hamwe na CVD, ibisekuru bizaza bya SiC nozzles bigera kubutaka bwa micron irangiza hamwe na geometrike igoye mbere itagerwaho mubutaka. Ihindagurika ryikoranabuhanga ryerekana karibide ya silikoni nkibikoresho byo guhitamo ibisekuruza bizaza sisitemu yo gusukura gaz.

Igihe cyo kohereza: Werurwe-20-2025