Carbide ya silicon na nitride ya silicon ifite ububobere buke hamwe nicyuma gishongeshejwe. Usibye kwinjizwa na magnesium, nikel, chromium alloy hamwe n'ibyuma bidafite ingese, nta mashanyarazi bafite ku bindi byuma, bityo bifite imbaraga zo kurwanya ruswa kandi bikoreshwa cyane mu nganda za aluminium electrolysis.

Muri iyi nyandiko, ubushakashatsi bwakorewe ruswa ya silicon karbide R-SiC na silicon nitride ihujwe na silicon karbide Si3N4-SiC mu gushonga kwa Al-Si alloy yashushe hashyizwe ahagaragara.

Dukurikije imibare yubushakashatsi bwikubye inshuro 9 yumukino wogukoresha ubushyuhe bwa 1080h muri 495 ° C ~ 620 ° C aluminium-silicon alloy yashonga, habonetse ibisubizo byisesengura bikurikira.

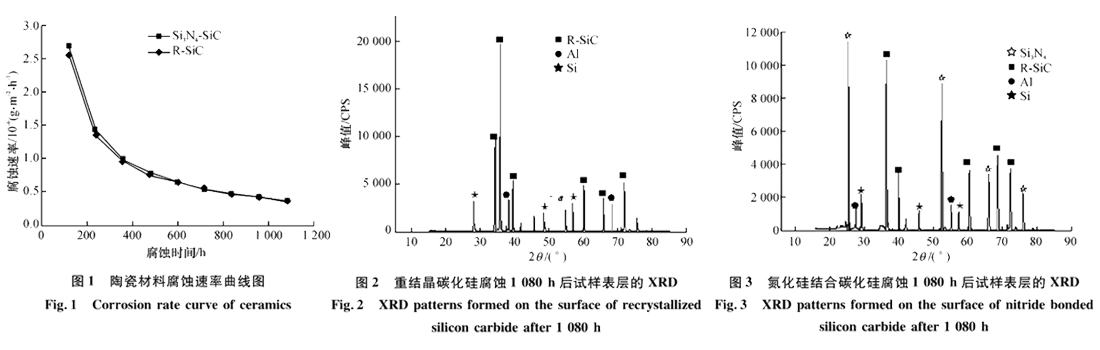

Ingero za R-SiC na Si3N4-SiC ziyongereye igihe cyo kwangirika kandi igipimo cya ruswa cyaragabanutse. Igipimo cyo kwangirika kijyanye na logarithmic isano ya attenuation. (ishusho 1)

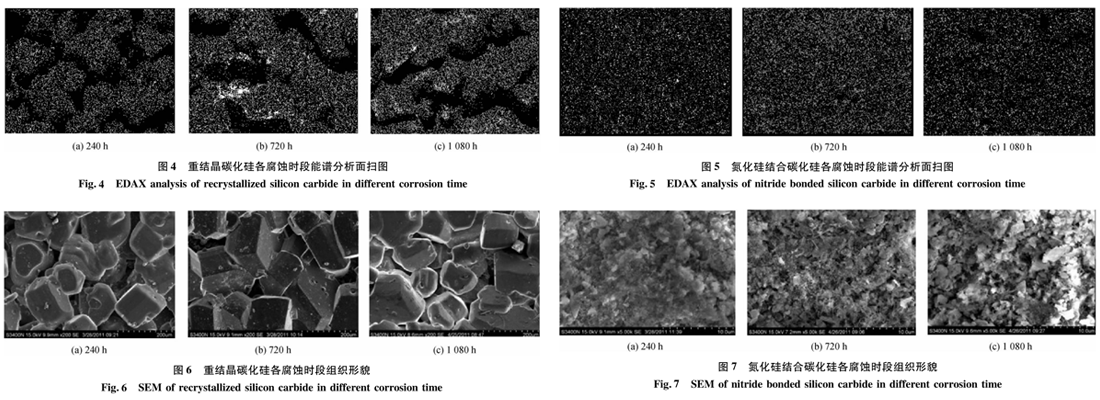

Ukoresheje isesengura ry'ingufu, ingero za R-SiC na Si3N4-SiC ubwazo nta aluminium-silikoni; muburyo bwa XRD, umubare munini wa aluminium-silikoni ni ubuso-busigaye bwa aluminium-silicon. (Ishusho 2 - Ishusho 5)

Binyuze mu isesengura rya SEM, uko igihe cyo kwangirika cyiyongera, imiterere rusange yintangarugero ya R-SiC na Si3N4-SiC irekuye, ariko nta byangiritse bigaragara. (Ishusho 6 - Ishusho 7)

Ubusumbane bwubuso σs / l> σs / g bwimiterere hagati ya aluminiyumu na ceramic, inguni itose θ hagati yimbere ni> 90 °, naho intera iri hagati ya aluminiyumu nibikoresho byamabati ntabwo itose.

Kubwibyo, ibikoresho bya R-SiC na Si3N4-SiC nibyiza cyane mukurwanya ruswa irwanya aluminium silicon yashonga kandi bifite itandukaniro rito. Nyamara, igiciro cyibikoresho bya Si3N4-SiC ni gito kandi cyakoreshejwe neza mumyaka myinshi.

Igihe cyo kohereza: Ukuboza-17-2018