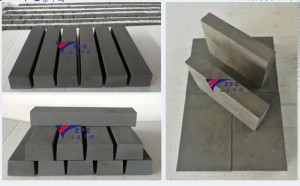

RBSC Silicon Carbide Ceramic tiles

RBSC Silicon Carbide Ceramic tiles have emerged as the premier solution for combating wear and corrosion in demanding industrial environments. These engineered ceramic tiles and linings deliver unmatched performance in material handling systems, extending equipment lifespan while optimizing operational efficiency across critical processes.

Engineering Superiority

Our precision-manufactured silicon carbide (SiC) components excel through unique material properties:

- Mohs Hardness 9.5(13 on updated scale) for extreme wear resistance

- 4–5× greater fracture toughness vs. nitride-bonded SiC alternatives

- 5–7× longer service life compared to traditional alumina linings

- Chemical inertness against acids, alkalis, and organic solvents (pH 0–14)

- Thermal stability maintaining integrity from -60°C to 1650°C

Customized Protection Solutions

Available in thicknesses from 8–45 mm, our ceramic linings adapt to diverse operational requirements:

- Impact-resistant configurations for chutes and hoppers

- Low-friction surfaces for conveyor systems

- High-purity grades for food/pharmaceutical applications

- Electrically insulating variants for explosive environments

Performance-Driven Applications

1. Material Handling Systems

- Slurry pipelines with 90% reduced erosion

- Mining trommels with 3× extended service cycles

- Cement plant cyclones surviving 50,000+ operating hours

2. Processing Equipment

- Coal pulverizer linings resisting 120 m/s particle impacts

- Chemical reactor vessels handling corrosive media

- Steel plant ductwork withstanding abrasive fly ash

3. Specialized Components

- Rotor blade coatings for centrifugal separators

- Wear plates for biomass processing

- Custom-shaped inserts for complex geometries

Economic Impact

The transition to silicon carbide linings demonstrates measurable benefits:

- 60–80% reduction in unplanned downtime

- 45% lower lifetime maintenance costs

- 30% energy savings through optimized material flow

- 90% recyclability of worn components

Installation & Adaptability

Engineered for seamless integration:

- Modular tile systems with interlocking designs

- High-strength epoxy or mechanical fixation

- On-site machining and retrofitting services

- Real-time wear monitoring compatibility

Future-Ready Innovations

Next-generation silicon carbide linings incorporate:

- Gradient density structures for impact absorption

- Self-lubricating surface treatments

- RFID-enabled wear tracking

- Hybrid ceramic-metal composite systems

From mining operations to chemical processing plants, silicon carbide ceramic linings represent the new standard in industrial wear protection. Their unique combination of mechanical resilience, chemical stability, and thermal endurance transforms equipment performance – reducing lifecycle costs while enhancing production reliability in the world’s most abrasive operating environments.

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.