Professional China Hollow Cone Tangential Whirl Nozzle - Green silicon carbide powder and silicon carbide micropowder – ZhongPeng

Professional China Hollow Cone Tangential Whirl Nozzle - Green silicon carbide powder and silicon carbide micropowder – ZhongPeng Detail:

Silicon carbide (SiC), also known as carborundum, is a semiconductor containing silicon and carbon with chemical formula SiC. It occurs in nature as the extremely rare mineral moissanite. Synthetic silicon carbide powder has been mass-produced since 1893 for use as an abrasive. Grains of silicon carbide can be bonded together by sintering to form very hard ceramics that are widely used in applications requiring high endurance, such as car brakes, car clutches and ceramic plates in bulletproof vests. Electronic applications of silicon carbide such as light-emitting diodes (LEDs) and detectors in early radios were first demonstrated around 1907. SiC is used in semiconductor electronics devices that operate at high temperatures or high voltages, or both. Large single crystals of silicon carbide can be grown by the Lely method; they can be cut into gems known as synthetic moissanite. Silicon carbide with high surface area can be produced from SiO2 contained in plant material.

Product Description

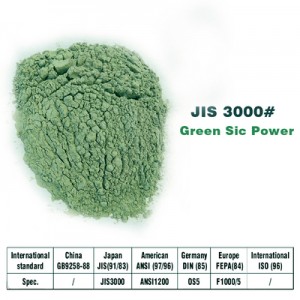

Green silicon carbide is suitable for processing hard alloy, metallic and non-metallic materials with hard and brittle feature such as copper, brass,aluminum, magnesium, jewel, optical glass, ceramics, etc. Super powder of it is also a kind of ceramics material.

Product detail pictures:

Related Product Guide:

A Review of Superior Radiant Infrared Tube Heaters, SiC ceramic heat exchager

FGD Full Cone Nozzle – For Maximum Spray Versatility- Desulphurization and Dust scrubber nozzle

Professional China Hollow Cone Tangential Whirl Nozzle - Green silicon carbide powder and silicon carbide micropowder – ZhongPeng, The product will supply to all over the world, such as: , , ,

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.