Online Exporter Silicon Carbide Beam - Wear-proof material outstanding against frictional wear in hot conditions – ZhongPeng

Online Exporter Silicon Carbide Beam - Wear-proof material outstanding against frictional wear in hot conditions – ZhongPeng Detail:

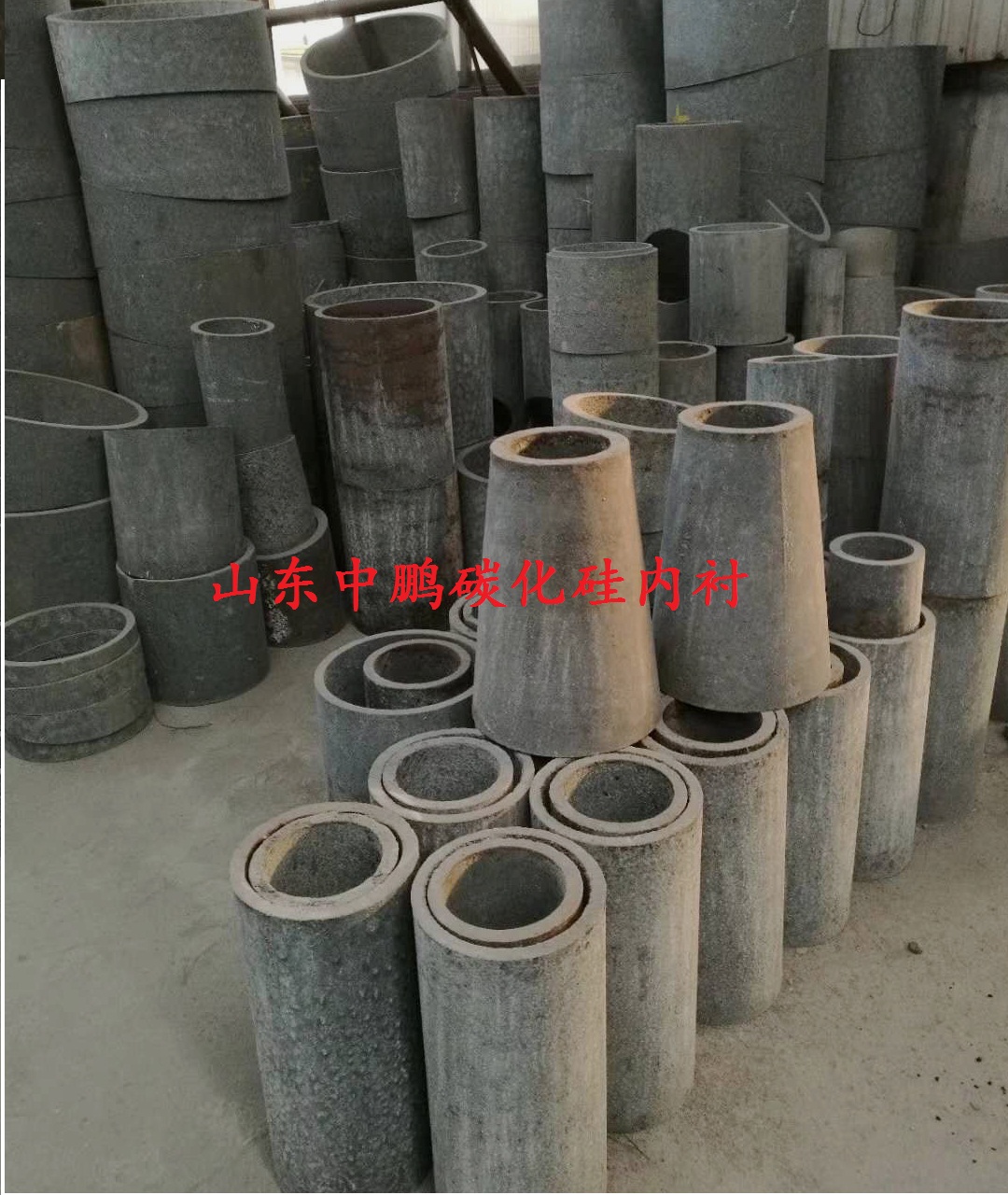

ZPC use silicon carbide ceramics for plant components which are subject to not only extreme abrasive wear but also high temperatures or stresses due to temperature fluctuations. ZPC is available in various quality grades depending on where it is used. Typical applications include coal dust distributors, cyclone linings and coke ramps. High-precision custom components, even for complex geometries, are used as wear-protection fittings in pumps, fans or hydraulic cyclones.

Product detail pictures:

Related Product Guide:

A Review of Superior Radiant Infrared Tube Heaters, SiC ceramic heat exchager

Understanding of Metal Tubing within Ceramic lining

Online Exporter Silicon Carbide Beam - Wear-proof material outstanding against frictional wear in hot conditions – ZhongPeng, The product will supply to all over the world, such as: , , ,

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.