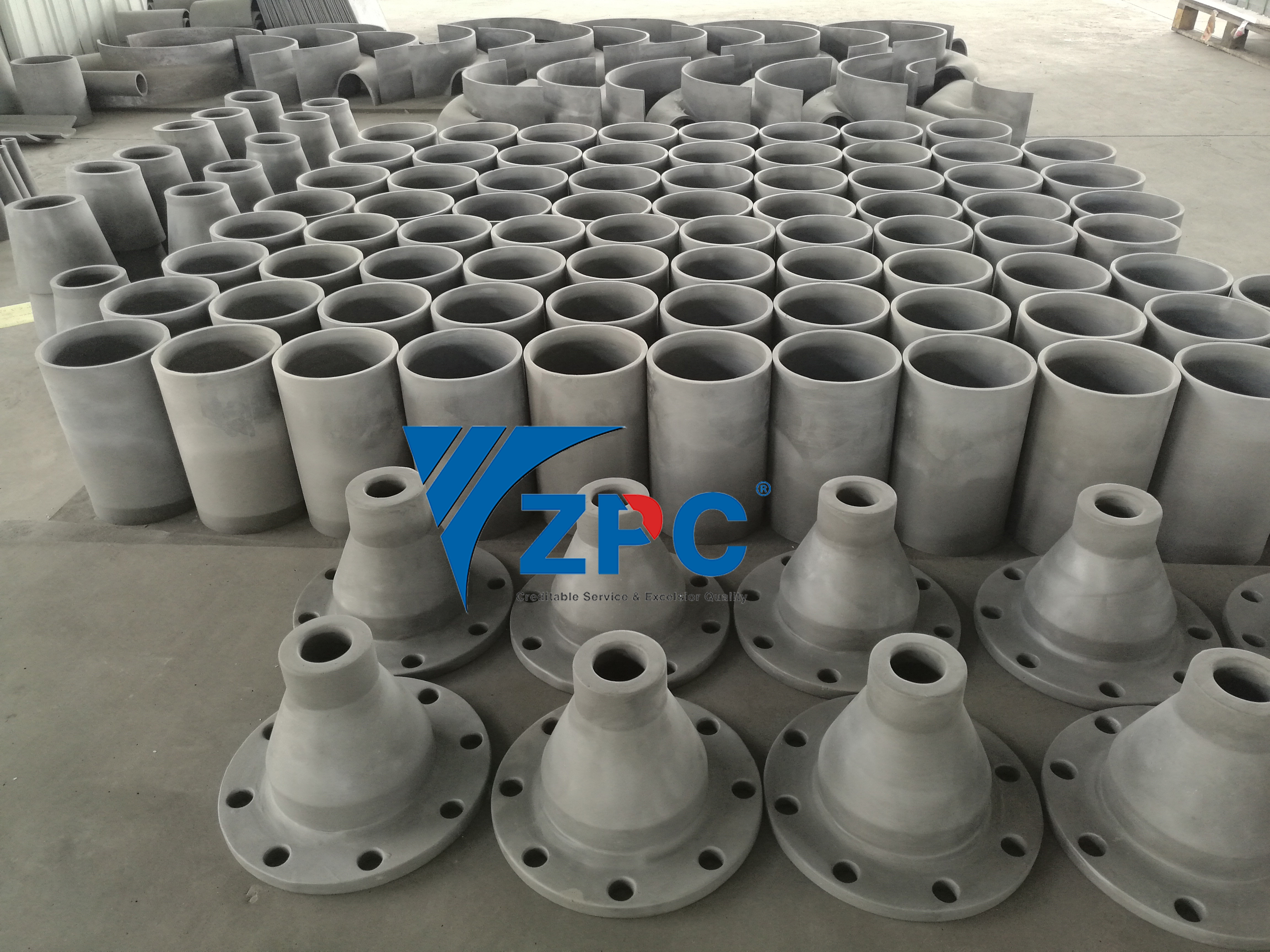

OEM Supply Cnc Flame Cutting Machine - wear resistance silicon carbide cylinder, cone, spigot, etc – ZhongPeng

OEM Supply Cnc Flame Cutting Machine - wear resistance silicon carbide cylinder, cone, spigot, etc – ZhongPeng Detail:

Silicon carbide ceramic: Moh’s hardness is 9.0~9.2, with excellent resistance to erosion and corrosion, excellent abrasion-resistance and anti-oxidation. It is 4 to 5 times stronger than nitride bonded silicon carbide. The service life is 7 to 10 times longer than alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes.

ZPC micronizer linings far outlast tiled and metallic liners. Drop in 1-pc liners eliminate all joints and wear areas. ZPC silicon carbide materials are thermal shock resistance and abrasion resistant which results in extended run times and reduced downtime. Main liners, vortex finders, feed sleeves, steam nozzles and ancillary wear shapes are possible with the ZPC repeatable process.

Product detail pictures:

Related Product Guide:

SiC FGD desulphurization nozzles

Acid scrubber

OEM Supply Cnc Flame Cutting Machine - wear resistance silicon carbide cylinder, cone, spigot, etc – ZhongPeng, The product will supply to all over the world, such as: , , ,

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.