OEM Factory for High Quality Radiant Heating Element 9kw - Kiln and furnace silicon carbide high temperature resistance, wear-resistant guide rail, plates – ZhongPeng

OEM Factory for High Quality Radiant Heating Element 9kw - Kiln and furnace silicon carbide high temperature resistance, wear-resistant guide rail, plates – ZhongPeng Detail:

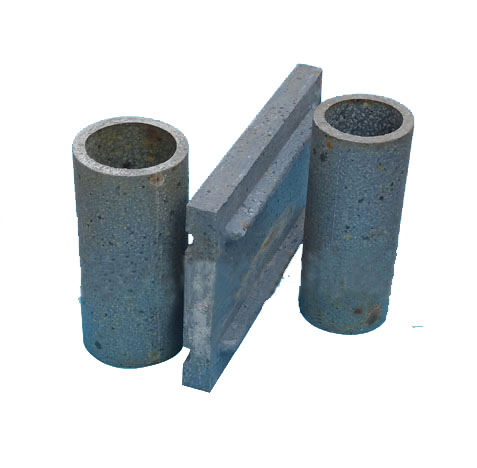

Oxide bonded silicon carbide products, kiln temperature resistance, wear-resistant guide rail

Advantages

Best first step for replacing metallic components

One-third the weight and a smoother surface then cast iron

Dimensional tolerance and superior thermal shock and oxidation resistance

Low cost/ high volume

Markets for Oxide Bonded Silicon Carbide

Mining

Red Metals

Aluminum

Industrial Process & Heating

Chemical

Petrochemical

Power Generation

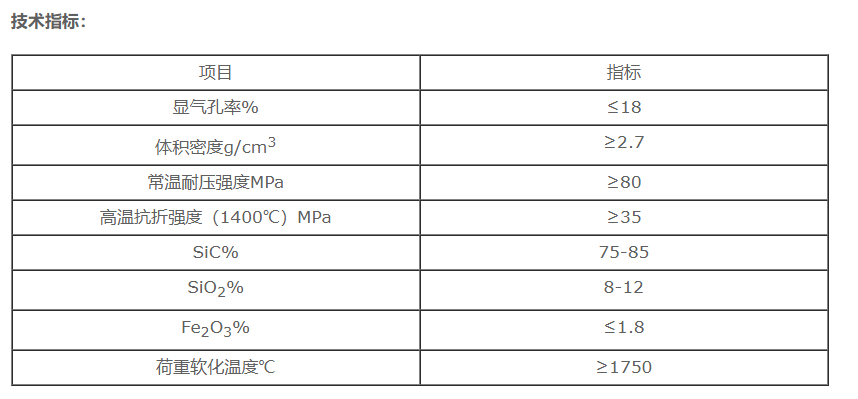

Technical Data:

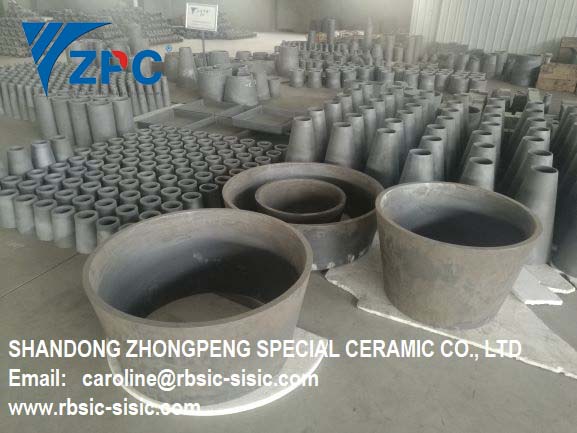

Product detail pictures:

Related Product Guide:

Silicon Carbide Ceramics for Industry

Relationship Between Mechanical Properties and Wear Resistance of Alumina-Zirconia Ceramic Composites

OEM Factory for High Quality Radiant Heating Element 9kw - Kiln and furnace silicon carbide high temperature resistance, wear-resistant guide rail, plates – ZhongPeng, The product will supply to all over the world, such as: , , ,

Shandong Zhongpeng Special Ceramics Co., Ltd is one of the largest silicon carbide ceramic new material solutions in China. SiC technical ceramic: Moh’s hardness is 9 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. SiC product’s service life is 4 to 5 times longer than 92% alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. The quotation process is quick, the delivery is as promised and the quality is second to none. We always persist in challenging our goals and give our hearts back to society.