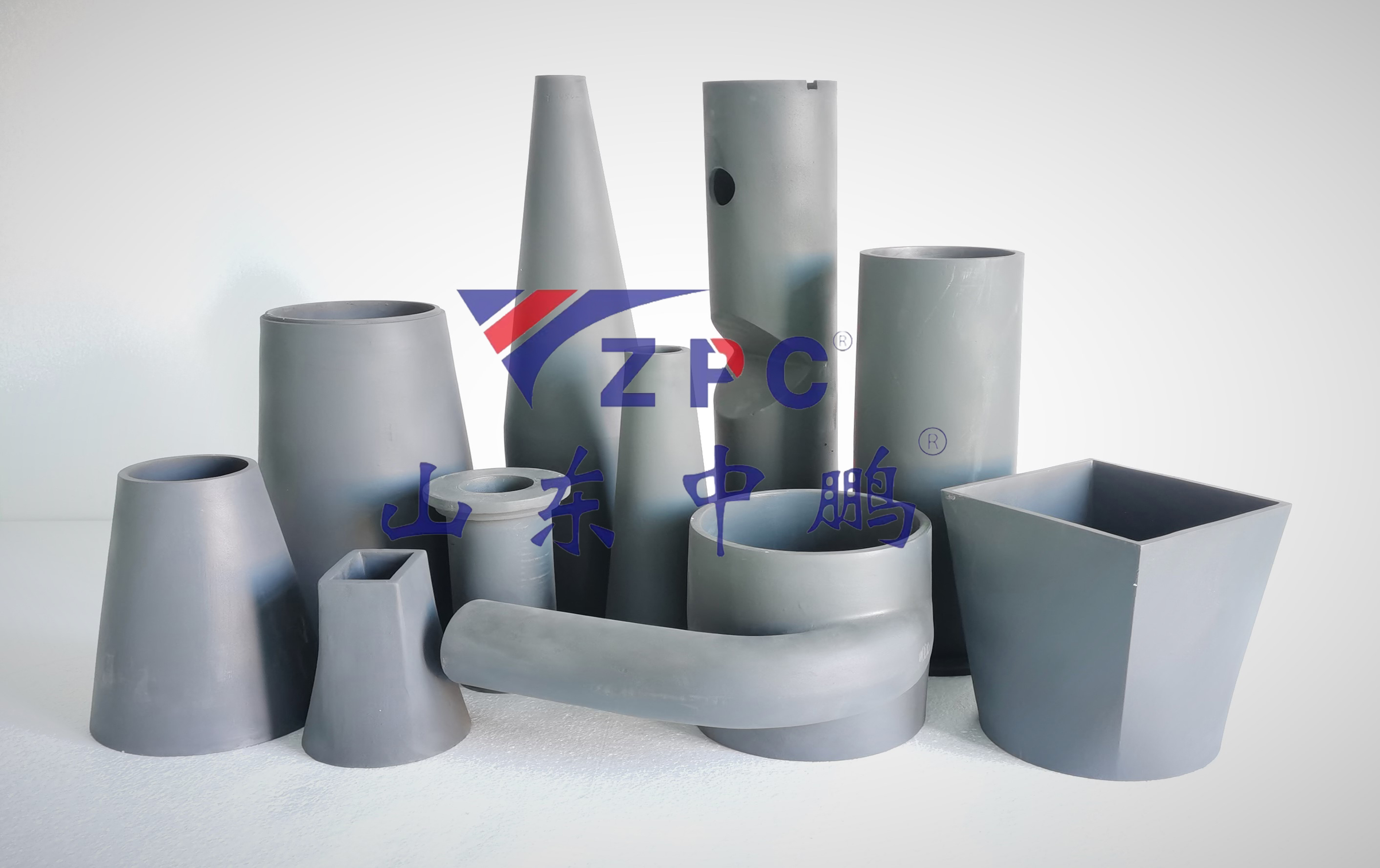

Silicon carbide ceramic liners

Silicon carbide kuvala zosagwira akalowa

Mapangidwe a Silicon Carbide (SiC) Zovala Zosamva Zovala:

(1) Mapangidwe Oyenda Panjira Yoyenda

Mzere wosalala, wowongoka kuchokera pakulowera kupita kumtunda umachepetsa kukana kwamadzi, kupangitsa ma SiC liner kuti azitha kutengera ntchito zosiyanasiyana zamafakitale.

(2) Advanced Atomization

MechanismLiquids amapangidwa ndi ma atomu kukhala madontho abwino kudzera pakugundana kwamphamvu komwe kumacheperako pang'onopang'ono pa liner ya SiC, kuwonetsetsa kufalikira kwa utsi wofanana.

(3) Chokhazikika, Chopanda Chotsekera

Njira yowongoka, yopanda coreless imachotsa zopinga zamkati, kukulitsa kutulutsa kwamadzimadzi mkati mwa mipope yotsekeka ndikuletsa kutsekeka.

(4) Njira Zapawiri Zotsitsira Zowonjezera Mwachangu

Imathandizira njira zopopera zolimba-cone komanso zosanjikiza, zomwe zimapereka ma angles ambiri komanso anti-clogging pakuchita bwino kwambiri.

Ubwino wapakati poyerekeza ndi zida zina:

(1) Kukaniza Kuvala Kosagwirizana

Kulimba: Ma liner a SiC amakwaniritsa kulimba kwa Mohs kwa 9.5 (vs. 8.0 kwa alumina ceramics, 6.0 pazitsulo za chromium yapamwamba), kuwapangitsa kuti azitha kupirira kuvala konyansa kwambiri pamatope a migodi, phulusa la malasha, ndi ufa wachitsulo.

Utali wautali: Moyo wautumiki umaposa 5-10 × zida zachikhalidwe (monga mphira kapena zomangira za polyurethane) pazogwiritsa ntchito kwambiri monga mphero za mpira kapena mapampu amatope.

(2) Kuwonongeka ndi Kusakhazikika kwa Chemical

Kukaniza kwa Acid/Alkali: Kumakana sulfuric acid (98%), sodium hydroxide (50%), ndi mchere wosungunuka (monga NaCl-KCl pa 800°C), pamene zitsulo zimawononga mofulumira ndipo ma polima amawonongeka.

Kuyipitsidwa kwa Zero: Malo osasunthika amatsimikizira chiyero mu semiconductor kapena kupanga batire la lithiamu, mosiyana ndi zitsulo zachitsulo zomwe zimakhala ndi leaching ya ion.

(3) Kukhazikika kwa Kutentha Kwambiri

Kupirira kwa Kutentha: Kumagwira ntchito mosalekeza pa 1,600 ° C (kuyerekeza ndi malire a alumina a 1,200 ° C) ndi kukulitsa pang'ono kwa kutentha (CTE: 4.0 × 10⁻⁶/℃), kuteteza kung'ambika mu ng'anjo kapena ng'anjo zosungunulira.

Thermal Shock Resistance: Imasunga kukhulupirika kwachipangidwe pansi pa kusinthasintha kwa kutentha kwachangu (mwachitsanzo kuzimitsa kuchokera ku 1,000 ° C mpaka kutentha kwachipinda), mosiyana ndi zoumba za ceramic.

(4) Mphamvu Yamagetsi ndi Mapangidwe Opepuka

Kutsika Kwambiri: Pansi pa SiC yopukutidwa (Ra <0.1 μm) imachepetsa kukana kwamadzimadzi ndi 30-50% motsutsana ndi zitsulo zolimba zachitsulo, kudula ndalama zopopa mphamvu.

Kuchepetsa Kulemera: Kuchulukana kwa 3.1 g/cm³ (kuyerekeza ndi zitsulo 7.8 g/cm³) kumathandizira kuyika ndikuthandizira zida zopepuka muzamlengalenga kapena mayunitsi opangira mafoni.

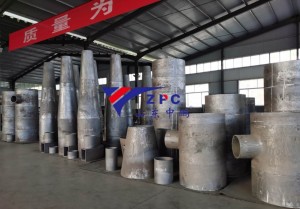

Shandong Zhongpeng Special Ceramics Co., Ltd ndi imodzi mwamayankho akulu kwambiri a silicon carbide ceramic ku China. SiC technical ceramic: Kuuma kwa Moh ndi 9 (Kulimba kwa Moh Chatsopano ndi 13), kukana kwambiri kukokoloka ndi dzimbiri, abrasion yabwino - kukana ndi anti-oxidation. Moyo wautumiki wa SiC ndi 4 mpaka 5 nthawi yayitali kuposa 92% alumina. MOR ya RBSiC ndi 5 mpaka 7 nthawi ya SNBSC, itha kugwiritsidwa ntchito pazinthu zovuta kwambiri. Ndondomeko yobwereketsa ndi yofulumira, yobweretsera ndi monga momwe inalonjezedwa ndipo khalidweli ndi lachiwiri kwa wina aliyense. Nthawi zonse timalimbikira kutsutsa zolinga zathu ndikubwezera mitima yathu kwa anthu.