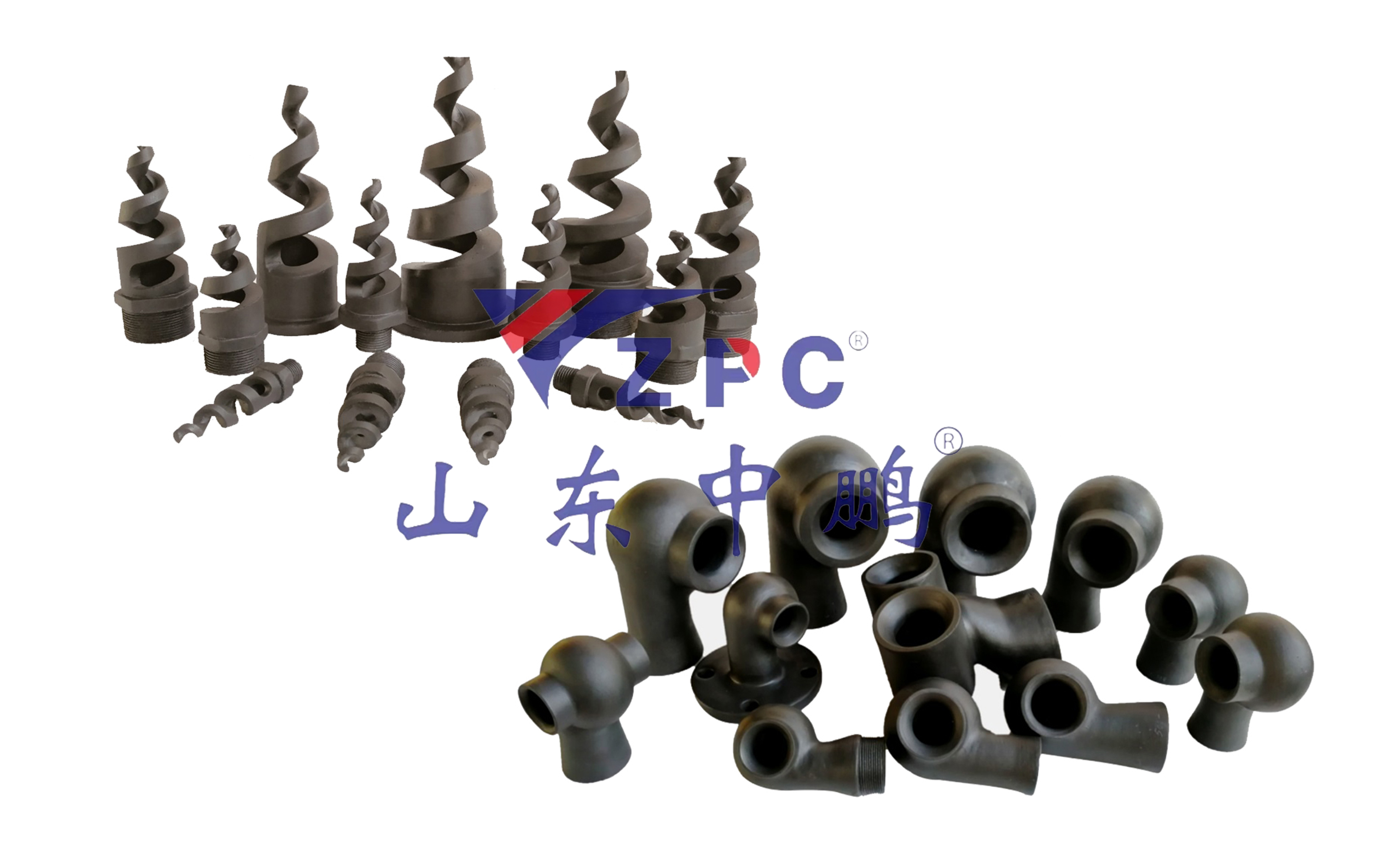

Monga gawo lalikulu la makina amakono oyeretsa gasi,silicon carbide FGD Nozzleszimagwira ntchito yofunika kwambiri m'mafakitale monga mphamvu yamafuta ndi zitsulo. Silicon carbide ceramic nozzle iyi yathetsa bwino botolo laukadaulo la zitsulo zachitsulo pansi pa dzimbiri lamphamvu komanso mavalidwe apamwamba kudzera m'mapangidwe apamwamba komanso kupititsa patsogolo zinthu zakuthupi, kuwongolera bwino kwambiri desulfurization.

1, Zinthu zakuthupi zimayala maziko a magwiridwe antchito

Kuuma kwa Mohs kwasilicon carbide ceramicsimafika pa 9.2, yachiwiri kwa diamondi, ndipo kulimba kwake kumadutsa katatu kuposa zoumba za alumina. Kapangidwe ka kristalo kokhazikika kameneka kamapangitsa kuti zinthuzo zikhale zolimba kwambiri, ndipo chifukwa cha slurry yothamanga kwambiri yokhala ndi makhiristo a gypsum (kuthamanga mpaka 12m / s), kuchuluka kwa kuvala pamwamba ndi 1/20 yokha ya ma nozzles achitsulo. M'malo osinthika a acid-base okhala ndi pH ya 4-10, kukana kwa silicon carbide kumakhala kosakwana 0.01mm / chaka, komwe kuli bwino kwambiri kuposa 0.5mm / chaka cha 316L chitsulo chosapanga dzimbiri.

Chiwopsezo chowonjezera kutentha kwazinthu (4.0 × 10 ⁻⁶/℃) chili pafupi ndi chitsulo, ndipo chikhoza kukhalabe chokhazikika pansi pa kutentha kwa 150 ℃. Silicon carbide ceramics yokonzedwa ndi reaction sintering process imakhala ndi kachulukidwe wopitilira 98% ndi porosity yochepera 0.5%, kuteteza bwino kuwonongeka kwamapangidwe komwe kumachitika chifukwa cha kulowa kwapakati.

2, Kulondola kwa atomization limagwirira ndi kuwongolera kumunda

Thesilicon carbide spiral nozzlekumawonjezera kwambiri kuthamanga kwa slurry, ndipo ndi pobowo yolondola, imaphwanya matope a miyala yamchere kukhala madontho ang'onoang'ono ndi ofanana. The dzenje conical kutsitsi kumunda mlingo Kuphunzira wopangidwa ndi dongosolo limeneli ndi lalikulu kwambiri, ndipo nthawi okhala m'malovu mu nsanja anawonjezera kwa masekondi 2-3, 40% apamwamba kuposa nozzles chikhalidwe.

3, Kufananiza kwamakina ndi kukhathamiritsa kwaukadaulo

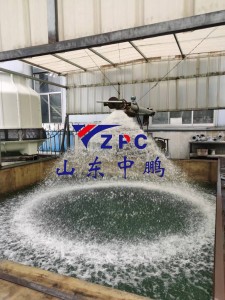

Mu nsanja yopopera yofananira,silicon carbide FGD nozzlesZokonzedwa m'njira ya chessboard zimagwiritsidwa ntchito, ndikutalikirana kwa 1.2-1.5 kuwirikiza kwa chulucho chopopera, ndikupanga zigawo 3-5 za zokutira. Dongosololi limatsimikizira kuti kufalikira kwa gawo la nsanja ya desulfurization kumapitilira 200%, kuonetsetsa kulumikizana kokwanira pakati pa mpweya wa flue ndi slurry. Ndi kuthamanga kwa nsanja yopanda kanthu kwa 3-5 m / s, kutayika kwamphamvu kwadongosolo kumayendetsedwa mkati mwa 800-1200 Pa.

Deta yogwira ntchito ikuwonetsa kuti mphamvu ya desulfurization ya dongosolo la FGD pogwiritsa ntchito ma silicon carbide nozzles imakhalabe yokhazikika kuposa 97.5%, ndipo chinyontho chochokera ku gypsum chimachepetsedwa mpaka 10%. Kukonzekera kwa zida zakulitsidwa kuchokera ku miyezi itatu kwa ma nozzles achitsulo mpaka zaka 3, ndipo mtengo wazinthu zosinthira zidatsika ndi 70%.

Kugwiritsa ntchito iziChithunzi cha FGDzikuwonetsa kudumpha kuchokera pazambiri kupita ku zida zenizeni zoteteza chilengedwe. Ndi kukhwima kwa ukadaulo wa 3D wosindikiza wa ceramic, mapangidwe a topology okhathamiritsa mawonekedwe amayendedwe oyenda atha kuzindikirika mtsogolomo, zomwe zitha kupititsa patsogolo luso la atomization ndi 15-20% ndikulimbikitsa ukadaulo wotsika kwambiri kuti ulowe gawo latsopano lachitukuko.

Nthawi yotumiza: Mar-24-2025