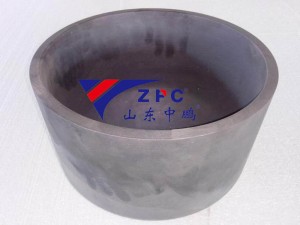

Reaction yomangidwa ndi silicon carbidezitsulozikuyimira kupambana muukadaulo wa refractory, wopereka ntchito zosayerekezeka m'malo otentha kwambiri. Zotengera za ceramic zapamwambazi zakhala zofunika kwambiri pazitsulo zonse, kuponyedwa molondola, uinjiniya wamakina, ndi mafakitale opangira mankhwala, kumapereka magwiridwe antchito apamwamba pomwe zida zachikhalidwe zimasowa.

Ubwino Waukadaulo Wapakati

Ma crucibles a RBSC amaposa alumina wamba ndi ma graphite mafani ake kudzera:

- Kutentha kwapadera (120–150 W/m·K pa 1000°C)

- Kukula kwamafuta otsika kwambiri (4.5×10⁻⁶/K)

- Kutentha kwamphamvu kupirira kuzizira kofulumira kwa 50+ (1600°C→25°C)

- Acid/alkali dzimbiri kukana (pH 0-14 mogwirizana)

- Kukhazikika kwa okosijeni mumlengalenga mpaka 1650 ° C

Metallurgical Mastery

Pakupanga zitsulo za aloyi ndi kusungunula zitsulo zopanda chitsulo (aluminium, mkuwa, zinki), zitsulo za RBSC zimathandiza:

- 20-30% imasungunuka mwachangu kudzera pakutengera kutentha kokwanira

- 99.95% kukonza zitsulo zachitsulo kudzera pamalo osagwira ntchito

- Kuchepetsa mapangidwe a slag kudzera pakuchepetsa kutentha kwapakati

- Kutalikitsa moyo wautumiki (3-5× wautali kuposa zitsulo zadongo-graphite)

Precision Casting & Mechanical Applications

Makina apadera a ma crucibles amathandizira zofunikira zamafakitale:

- Kukhazikika kwamapangidwe pansi pa 15-20 MPa kupsinjika kwamakina

- Kukhazikika kwapang'onopang'ono (± 0.1% kusintha kwa volumetric pa 1500 ° C)

- Kukonzekera kopanda kuipitsidwa kwa magawo amlengalenga

- Kuchita kodalirika pamakina oponya ma centrifugal

Chemical Processing Ubwino

Ma RBSC crucibles amalimbana ndi zovuta pakuphatikizika kwamankhwala:

- Kukhala ndi mchere wosungunuka (mwachitsanzo, NaOH, KNO₃)

- Ntchito yokhazikika pamachitidwe a sulfidation / chlorination

- Kukana kwa dzimbiri motsutsana ndi HF mpaka 800 ° C

- Kusungidwa koyera pakuchotsa zinthu zapadziko lapansi

Ntchito Economics

Ngakhale ndalama zoyambira ndi 40-60% kuposa zida zachikhalidwe, mayankho a RBSC amapereka:

- 70% kuchepetsa m'malo pafupipafupi

- 25-35% kupulumutsa mphamvu pogwiritsa ntchito kutentha kwabwino

- 90% yobwezeretsanso zinthu kudzera pakuwotchanso kwamafuta

- Zofunikira pakukonza pafupi ndi zero

Zosintha Zapadera Zamakampani

1. Titanium Alloy Production

- Imalimbana ndi ma reactive Ti imasungunuka pa 1700 ° C

- Imaletsa kuipitsidwa kwa carbon pick-up

2. Battery Material kaphatikizidwe

- Imathandizira kukonza ma cathode a LiCoO₂

- Imakana kuwonongeka kwa mchere wa lithiamu

3. Kukula kwa Crystal Semiconductor

- Imayenderana ndi vacuum yapamwamba kwambiri

- Imathetsa kuipitsidwa kwa silicon carbide

Future-Forward Design

Zopangira zamakono za RBSC zimaphatikizapo zinthu zapamwamba:

- Mapangidwe a gradient porosity kuti azitha kuwongolera mpweya

- Zovala za Nanoscale zimakulitsa kukana kwa slag

- Zophatikizika zama sensor zotenthetsera kuti ziwunikire ndondomeko

Kuchokera pakufufuza kwa labotale mpaka kupanga zinthu zambiri zamafakitale, ma silicon carbide crucibles omwe amalumikizidwa ndi ma silicon carbide akupitiliza kutanthauziranso kuthekera kwamafuta. Kuphatikizika kwawo kwapadera kwa kutentha, makina, ndi mankhwala kumawaika kukhala njira yabwino yopangira ntchito zotentha kwambiri za m'badwo wotsatira, kuyendetsa bwino komanso kuwongolera kwamtundu m'magawo angapo opanga zinthu zapamwamba.

Nthawi yotumiza: Mar-20-2025