Silicon carbide (SiC) ceramicsamadziwika chifukwa cha mphamvu zawo zosaneneka, kukana kutentha, komanso kulimba. Katunduwa amawapangitsa kukhala abwino kuti agwiritsidwe ntchito m'malo ovuta, monga injini zazamlengalenga kapena makina opanga mafakitale. Koma kodi zida zapamwambazi zimapangidwa bwanji? Tiyeni tiwononge ndondomekoyi pang'onopang'ono.

1.Kukonzekera Kwazinthu Zopangira

Zonse zimayamba ndi ufa wapamwamba wa silicon carbide. Ganizirani izi ngati "ufa" wophikira "keke" ya ceramic. Pofuna kukonza zinthu zomaliza, zowonjezera zowonjezera - monga aluminiyamu oxide kapena boron compounds - zimasakanizidwa. Zowonjezera izi zimakhala ngati guluu pakapita nthawi, zimathandiza kuti tinthu ting'onoting'ono tigwirizane bwino.

2. Kupanga Ceramic

Kenako ufawo umasinthidwa kukhala mawonekedwe owumbika. Njira ziwiri zodziwika zimagwiritsidwa ntchito:

Kupondereza: Ufawu umakanizidwa kukhala mawonekedwe enaake pogwiritsa ntchito kuthamanga kwambiri, kofanana ndi kuphatikizira matalala mu chipale chofewa.

Kuumba jekeseni: Ufawu umasakanizidwa ndi chomangira kwakanthawi (monga sera) kuti apange chisakanizo chofanana ndi mtanda, chomwe chimabayidwa mu nkhungu kuti zikhale zovuta.

Panthawi imeneyi, zinthuzo zikadali zosalimba—monga chosema chamchenga wouma—ndipo ziyenera “kuphikidwa” kuti zikhale zamphamvu.

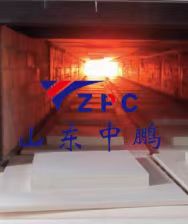

3. Njira ya Sintering

Apa ndi pamene matsenga amachitika. Ceramic yooneka bwino imatenthedwa mu ng'anjo yapadera pa kutentha kwambiri (nthawi zambiri kuposa 1,800 ° C). Panthawi ya sintering, zinthu ziwiri zazikulu zimachitika:

Particles Bond: Njere za silicon carbide zimayandikira, kuchotsa mipata ndikupanga cholimba.

Ntchito Yowonjezera: Zowonjezera zimasungunuka pang'ono, ndikupanga "mlatho" pakati pa tinthu tating'onoting'ono kuti tilimbikitse kulimba.

Chilengedwe cha m’ng’anjocho chimasamalidwa bwino—nthawi zina chimadzadza ndi mpweya wosagwira ntchito—kuteteza zinthu zosafunika.

4. Kumaliza Kukhudza

Pambuyo pa sintering, ceramic ikhoza kuchitidwanso chithandizo chowonjezera kuti chiwongolere ntchito yake:

Kupukutira: Kwa ntchito zomwe zimafuna malo osalala (mwachitsanzo, zosindikizira kapena ma bearings).

Kupaka: Wosanjikiza wocheperako woteteza (monga silicon nitride) ukhoza kuwonjezeredwa kuti ulimbikitse kukana kuvala.

Machining: Kudula bwino kapena kubowola kuti mukwaniritse miyeso yomaliza.

Chifukwa Chake Njirayi Ili Yofunika

Chinsinsi cha mphamvu ya silicon carbide chagona momwe ma atomu ake amamangirira panthawi ya sintering. Kutentha kwapamwamba kumapanga mgwirizano wazitsulo zolimba za silicon-carbon, zomwe zimagonjetsedwa ndi kutentha, dzimbiri, ndi kupsinjika kwa thupi. Zowonjezera komanso kuwongolera kutentha kumatsimikizira kuti chinthu chomaliza sichingokhala chovuta komanso cholimba mokwanira kuti chisaphwanyike.

Chithunzi Chachikulu

Kuchokera pama turbines otsogola kupita ku machitidwe owongolera kuipitsidwa, zoumba za silicon carbide zimagwira ntchito yofunika kwambiri paukadaulo wamakono. Ngakhale kuti kupanga ndizovuta, ndikusamala bwino kwa sayansi ndi uinjiniya komwe kumapangitsa ufa wosavuta kukhala chinthu chomwe chimatha kupirira zovuta kwambiri.

Pamene kafukufuku akupita patsogolo, njira zatsopano-monga zosindikizira za 3D za ceramic-zikutuluka, ndikulonjeza kuti zidzagwiritsidwa ntchito mwatsopano pazinthu zodabwitsazi.

Nthawi yotumiza: Mar-19-2025