valani matailosi a chitoliro osamva - matailosi a silicon carbide ndi matailosi a alumina

Reaction bonded silicon carbide (SiSiC kapena RBSIC) ndi chinthu choyenera kuvala, chomwe ndi

makamaka oyenera abrasive amphamvu, coarse particles, gulu, ndende, kuchepa madzi m'thupi ndi

ntchito zina. Amagwiritsidwa ntchito kwambiri m'makampani amigodi, mafakitale azitsulo, makampani opanga ma coral, mankhwala

mafakitale, zopangira zopangira mafakitale, kusindikiza makina, mankhwala opangidwa ndi sandblasted ndi zowunikira etc.

Chifukwa cha kuuma kwabwino kwambiri komanso kukana kwa abrasive, kumatha kuteteza bwino gawo lomwe likufunika kuvala

chitetezo, kuti atalikitse moyo wautumiki wa zida.

Moyo wautumiki wa SiC ceramics ndi wautali kwambiri kuposa wa 92% alumina ceramics.

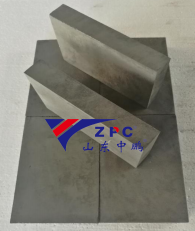

Momwe mungadziwire ndikupeza mbale zapamwamba za silicon carbide zosavala, matailosi, ma liner?

Matailosi a silicon carbide osamva kuvala, ma liner, mapaipi akugwiritsidwa ntchito kwambiri pantchito zamigodi.

Mfundo zotsatirazi ndi zanu:

1. Ndondomeko ndi ndondomeko:

Pali mitundu yambiri ya SiC pamsika. Timagwiritsa ntchito zolemba zenizeni zaku Germany. M'mayeso apamwamba a labotale, Kukokoloka kwazinthu zathu ㎝³ kumatha kufika 0.85 ± 0.01;

2. Kuuma:

Matailo a SiC amapangidwa mu ZPC: kuuma kwatsopano kwa Mohs: 14.55 ± 4.5 (MOR, psi)

3. Kachulukidwe:

Kuchuluka kwa matailosi a ZPC SiC ndi pafupifupi 3.03 + 0.05.

4. Makulidwe ndi Pamwamba:

Matailo a SiC opangidwa mu ZPC popanda ming'alu ndi pores, okhala ndi malo athyathyathya ndi m'mphepete mwawo ndi ngodya.

5. Zida zamkati:

Silicon carbide kuvala zosagwira liner / matailosi ali ndi zida zabwino komanso zofananira zamkati ndi zakunja.

If any questions, please feel free to contact us: info@rbsic-sisic.com

■Zofotokozera:

| Kanthu | Chigawo | Deta |

| Kutentha kwa ntchito | ℃ | 1380 ℃ |

| Kuchulukana | G/cm3 | >3.02 |

| Open porosity | % | <0.1 |

| Mphamvu yopindika -A | Mpa | 250 (20 ℃) |

| Mphamvu yopindika -B | MPa | 280 (1200 ℃) |

| Modulus ya elasticity-A | GPA | 330 (20 ℃) |

| Modulus ya elasticity -B | GPA | 300 (1200 ℃) |

| Thermal conductivity | W/mk | 45 (1200 ℃) |

| Coefficient ya kukula kwa kutentha | K-1 × 10-6 | 4.5 |

| Kukhazikika | / | 13 |

| Alkaline wopanda asidi | / | zabwino kwambiri |

■Mawonekedwe ndi makulidwe omwe alipo:

makulidwe: kuchokera 6mm mpaka 25mm

Mawonekedwe Okhazikika: mbale ya SISIC, Pipe ya SISIC, SiSiC Three Links, SISIC Elbow, SISIC Cone Cyclone.

Zindikirani: Makulidwe ena ndi mawonekedwe amapezeka mukafunsidwa.

■Kuyika:

M'bokosi la makatoni, odzaza ndi phale lamatabwa lofukizidwa ndi ukonde wolemera 20-24MT/20′FCL.

■Zopindulitsa zazikulu:

1. Kukana kovala bwino kwambiri, kukana kwamphamvu ndi kukana kwa dzimbiri;

2. Kusalala kwabwino kwambiri komanso kukana kutentha kwambiri mpaka 1350 ℃

3. Easy unsembe;

4. Moyo wautali wautumiki (ndi pafupifupi nthawi 7 kuposa wa alumina ceramic ndi nthawi 10 kuposa wa

polyurethane

Chitsanzo cha ngodya ikukhudza abrasion Mlingo wocheperako wotsetsereka

Kutuluka kwa zinthu zonyezimira kukafika pamalo osaya kapena kukadutsa mofananiza, mtundu wa mavalidwe omwe umachitika pakasemphana umatchedwa sliding abrasion.

Zopangira zida zapamwamba za silicon carbide zimapereka kukana komanso kukana kwa dzimbiri matailosi a ceramic ndi kuyanika. Zogulitsa izi zatsimikiziridwa kuti zidagwiritsidwa ntchito potumiza, kukonza, ndi kusunga. Matailosi athu amatha kupangidwa ndi makulidwe kuyambira 8 mpaka 45mm. m'pofunika kuonetsetsa kuti mukhoza kupeza zofunika mankhwala. SiSiC: Kuuma kwa Moh ndi 9.5 (kuuma kwa Moh Watsopano ndi 13), kukana kwambiri kukokoloka ndi dzimbiri, kuphulika kwabwino kwambiri - kukana ndi anti-oxidation. Ndi mphamvu 4 mpaka 5 kuposa nitride yomangika silicon carbide. Moyo wautumiki ndi nthawi 5 mpaka 7 kuposa zinthu za alumina. MOR ya RBSiC ndi 5 mpaka 7 nthawi ya SNBSC, itha kugwiritsidwa ntchito pazinthu zovuta kwambiri. Kuvala zomangira zomangira za ceramic ndizothandiza kupititsa patsogolo magwiridwe antchito, magwiridwe antchito, kuchepetsa mtengo wokonza ndikuwonjezera phindu.

Ma ceramics olondola ali ndi chidziwitso chakuthupi, ukadaulo wogwiritsa ntchito komanso luso laukadaulo. Izi zitha kuonetsetsa kuti mayankho abwino amaperekedwa kwa makasitomala athu. Matailo a Silicon carbide ceramic matailosi ndi lining nthawi zambiri amagwiritsidwa ntchito ngati mvula yamkuntho, machubu, chute, hoppers, mapaipi, malamba otumizira ndi makina opanga. M'dongosololi, pali zinthu zoyenda zomwe zikuyenda pamtunda. Chinthucho chikatsetsereka pa chinthucho, chimatha pang'onopang'ono mpaka palibe chomwe chimatsalira. M'malo ovala kwambiri, izi zimatha kuchitika pafupipafupi ndikubweretsa mavuto okwera mtengo. Chomera chachikulu chimasungidwa pogwiritsa ntchito zinthu zolimba kwambiri, monga silicon carbide ceramics ndi alumina ceramics ngati chingwe choperekera nsembe. Nthawi yomweyo, zoumba za silicon carbide zimatha kupirira nthawi yayitali zisanathe kusinthidwa, moyo wautumiki wa silicon carbide ceramic ndi nthawi 5 mpaka 7 kuposa zinthu za alumina.

Valani Matayilo a Ceramic Osasunthika a Silicon Carbide & Katundu wa Lining:

Kusamva mankhwala

Zowonongeka ndi magetsi

Kukokoloka kwa makina & kusamva ma abrasion

Zosinthika

Ubwino wa Ceramic Wear Resistant Tiles & Linings:

Itha kugwiritsidwa ntchito pomwe kulolerana kolimba kapena zingwe zopyapyala zimafunikira

Itha kugwiritsidwa ntchito kukonzanso malo omwe amakonda kuvala

Itha kugwiritsidwa ntchito ndi njira zingapo zolumikizira monga kuwotcherera ndi zomatira

Mwambo wopangidwira ntchito zinazake

Kulimbana ndi dzimbiri

Njira yochepetsera kuvala yopepuka

Imateteza magawo osuntha omwe amakhala ndi mavalidwe apamwamba

Amatuluka & amapambana njira zochepetsera kuvala

Kutentha kwapamwamba kwambiri kogwiritsa ntchito mpaka 1380 ° C

1, Iron ndi zitsulo chomera: 1, sintering makina ng'oma chosakanizira akalowa 2, ng'oma wokutidwa ceramic mphira 3, zimakupiza impeller 4, chimbale wodyetsa, youma zakuthupi ufa 5, coke hopper, Converter bin, coke bin, chimphepo fumbi wotolera.

2, Mphamvu chomera: 1. Mpira mphero kubwereketsa, mphero volute, sing'anga liwiro mphero kubwereketsa, ufa chigongono chitoliro, mphepo yamkuntho fumbi wokhometsa, silo, hopper 2, malasha hopper, coarse ndi olekanitsa ufa wabwino, malasha mphero kubwereketsa, malasha kufalitsa hopper 3, malasha hopper wa mlatho kanyalanya, pakati mkuwa ndi hopper outlet cholekanitsa ufa wosalala ndi wabwino, wotulutsa mpweya wokwanira 4 Mitundu yosiyanasiyana yaposachedwa, yozungulira yozungulira komanso yochepetsera kutentha kosamva kutentha kwa ma boiler oyaka; mapaipi ndi zigongono za ceramic zosamva kwambiri, zoyatsira za ceramic, mafani a ceramic, zonyamulira za ceramic, mavavu a ceramic, ndi zina zotero; mbali zosiyanasiyana zosamva kuvala monga mipira yopera, manja odzigudubuza, ma disks opera, matailosi a disc, mphete zopera, mipira yamphuno ndi zina zosagwirizana ndi mphero zamakala apakati; mapaipi, damper yosamva kuvala ndi mafani amitundu yosiyanasiyana yopuntha ndi kuchotsa phulusa; Mipira Mitundu yonse ya mphero imakhala ndi (kapena ayi) matailosi a bawuti, mbale zomangira, chitoliro chozungulira, mphete ya giya, mpira wachitsulo wochepa wa chromium alloy, etc.; gudumu, mbale yomenyera, mbedza yolondera, zida, cholekanitsa, chitoliro cha gasi chamoto wotentha kwambiri, ndi zina zotere zopangira malasha; zipangizo zofunika mitundu yosiyanasiyana ya makina ophwanya.

3, Paper mphero: 1. Pulverized malasha chitoliro

Zogulitsa zazikulu ndi ntchito: 1. Mapaipi a ceramic osagwira ntchito ku mafakitale: mitundu yonse ya ceramic yosagwira komanso yotentha kwambiri yokhala ndi malasha opukutidwa, tailings, slag slurry, mapaipi oyendetsa matope, chigongono, chigongono, chowotchera malasha, mphero yamalasha, chopondera chamoto, chopondera chamoto, chopondera chamoto, chigoba, chigongono kuvala mbiya ya mine magnetic separator; 2. Valani zosagwira ceramic fan: mitundu yonse ya kutentha kugonjetsedwa, kusavala, anti-corrosion fan impeller ndi volute, kuphatikizapo centrifugal fan, axial flow fan, static blade, chosunthika chosinthika cha fan, suction fan, fafa yopopera, fani ya sintering, fani yolekanitsa ufa, kuchotsa mutu wa fumbi ndi zina zotero; 3. Valani kugonjetsedwa ceramic akalowa pampu ndi valavu: ceramic akalowa, mpope impeller, chipolopolo, baffle, chigongono chitoliro, pneumatic kuchotsa phulusa ndi mpweya kufala valavu ndi Chalk zosiyanasiyana slurry, slag slurry, matope, tailings ndi machitidwe ena mayendedwe. 4. Valani zokutira za ceramic zosagwira ntchito: mitundu yonse ya zokutira za ceramic zosagwirizana ndi kutentha kwambiri komanso kutentha kwambiri zimagwiritsidwa ntchito ngati fan volute, chigoba chitoliro, potulutsa mphero, chitoliro chowoneka bwino komanso cholekanitsa bwino, chute, hopper ndi valavu. 5. Valani zida zolekanitsa zosagwirizana ndi maginito: magawo oyenda ndi zida zosiyanasiyana zowuma ndi zonyowa zamchere, kuphatikiza ng'oma ya maginito olekanitsa, poyambira pansi, chute, mapaipi, mapampu amatope osiyanasiyana, slurry pump volute, impeller, ndi mapaipi otumizira. 6. Ukadaulo wa kupopera mbewu mankhwalawa pamwamba: pogwiritsa ntchito zida zaposachedwa kwambiri zapadziko lonse lapansi za inverter pulse arc ndi mfuti yopopera mwachangu ya arc, zida zosiyanasiyana zachitsulo zosavala komanso zotsutsana ndi dzimbiri zimapopera pagawo lachitsulo chachitsulo kuti apange wosanjikiza wosamva komanso woteteza kutu. Itha kupereka chitetezo chokwanira kwa mitundu yonse yamphamvu yapakati kuvala dzimbiri.

Shandong Zhongpeng ZPC ceramics ndi bizinesi yomwe imagwira ntchito kwambiri popanga zoumba zamafakitale, zomwe zimagwira ntchito mu R&D ndikupanga zoumba za silicon carbide. Titha kukonza zinthu zadothi molingana ndi zojambula zanu, zomwe zimagwira ntchito yopanga kukula kwakukulu, ndodo yolondola kwambiri yadothi, chitoliro cha ceramic, mphete ya ceramic, mbale ya ceramic, flange ya ceramic, dothi la ceramic, ndi makonda akulu akulu osagwira ntchito.

Shandong Zhongpeng Special Ceramics Co., Ltd ndi imodzi mwamayankho akulu kwambiri a silicon carbide ceramic ku China. SiC ukadaulo wa ceramic: Kulimba kwa Moh ndi 9 (Kulimba kwa Moh Chatsopano ndi 13), kukana kwambiri kukokoloka ndi dzimbiri, abrasion yabwino - kukana ndi anti-oxidation. Moyo wautumiki wa SiC ndi 4 mpaka 5 nthawi yayitali kuposa 92% alumina. MOR ya RBSiC ndi 5 mpaka 7 nthawi ya SNBSC, itha kugwiritsidwa ntchito pazinthu zovuta kwambiri. Ndondomeko yobwereketsa ndi yofulumira, yobweretsera ndi monga momwe inalonjezedwa ndipo khalidweli ndi lachiwiri kwa wina aliyense. Nthawi zonse timalimbikira kutsutsa zolinga zathu ndikubwezeranso mitima yathu kwa anthu.