1、 Applied to gemstone materials

In the gemstone industry, silicon carbide is also known as "moissanite". The commonly seen materials on the market are artificially synthesized moissanite, while natural moissanite is extremely rare, so rare that it only appeared in meteorite craters 50000 years ago.

(1) High temperature resistance products:

Utilizing the characteristics of corrosion resistance, high temperature resistance, high strength, good thermal conductivity, and impact resistance of silicon carbide materials, they can be used for various smelting furnace linings, high-temperature furnace components, silicon carbide plates, lining plates, supports, and ladles. On the other hand, high-temperature indirect heating materials can be used in the non-ferrous metal smelting industry, such as vertical distillation furnaces, arc plates for zinc powder furnaces, thermocouple protection tubes, etc; Used for producing advanced silicon carbide ceramic materials that are wear-resistant, corrosion-resistant, and high-temperature resistant; It can also be used to make rocket nozzles, gas turbine blades, etc. In addition, silicon carbide is also one of the ideal materials for solar water heaters on highways, aircraft runways, etc. Therefore, silicon carbide also has a common name of "refractory sand", which, although very common, fully demonstrates its refractory properties.

(2)Wear resistant and corrosion resistant products:

Mainly because silicon carbide has a high hardness, with a Mohs hardness of 9.2-9.8, second only to the world's hardest diamond (level 10), it is commonly known as "gold steel sand". It also has good chemical stability and certain toughness, and can be used to make grinding wheels, sandpapers, sand belts, oilstones, grinding blocks, grinding heads, grinding pastes, and for grinding and polishing monocrystalline silicon, polycrystalline silicon, and piezoelectric crystals in the electronic industry in optical products.

(3)Metallurgical raw materials:

Silicon carbide can be used as a deoxidizer for steelmaking and a modifier for cast iron structure. It can also be used as a raw material for manufacturing silicon tetrachloride and is the main raw material for the silicone resin industry. Silicon carbide deoxidizer is a new type of strong composite deoxidizer that replaces traditional silicon powder and carbon powder for deoxidation. Compared with the original process, it has more stable physical and chemical properties, good deoxidation effect, shortened deoxidation time, saved energy, improved steelmaking efficiency, improved steel quality, reduced raw material consumption, reduced environmental pollution, improved working conditions, and enhanced comprehensive economic benefits of electric furnaces, all of which have important value.

3、 Silicon carbide optical reflector material

Ceramic materials manufactured using the special functions of ceramics in terms of physical properties such as sound, light, electricity, magnetism, and heat are called functional ceramics. There are various types of functional ceramics with different uses, and silicon carbide is mainly used as a reflective mirror material in the field of functional ceramics. SiC ceramics have high specific stiffness, good thermal and chemical stability, low thermal deformation coefficient, and resistance to space particle irradiation. Through special manufacturing processes, lightweight mirror bodies can be obtained.

4、 As a semiconductor material

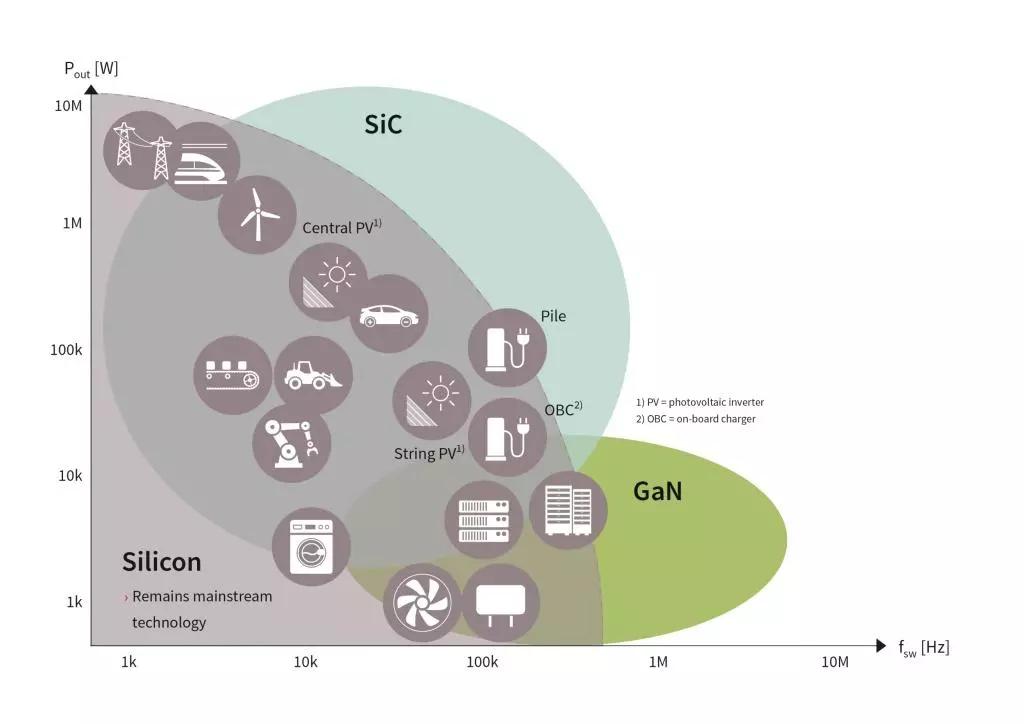

The third generation semiconductor is a key core material and electronic component supporting the innovation, development, transformation and upgrading of national defense armaments, 5G mobile communications, energy Internet, new energy vehicles, rail transit and other industries. Because of its important role in national defense security, intelligent manufacturing, industrial upgrading, energy conservation and emission reduction and other major strategic needs, it is becoming the technical commanding point of competition in the world.

SiC, as a typical representative of third-generation semiconductor materials, is currently one of the most mature and widely used wide bandgap semiconductor materials in crystal production technology and device manufacturing. It has formed a global material, device, and application industry chain. It is an ideal semiconductor material for high-temperature, high-frequency, radiation resistant, and high-power applications. Due to the significant reduction in energy consumption of electronic devices, silicon carbide power devices are also known as the "green energy devices" driving the "new energy revolution".

5、 Reinforcing and toughening agent

In addition to the above applications, silicon carbide whiskers or silicon carbide fibers have been widely used as excellent reinforcing and toughening agents in composite materials with metal based or ceramic based materials in fields such as machinery, chemical engineering, national defense, energy, and environmental protection.

Post time: Mar-22-2025