From transportation pipelines to new energy vehicles, from high-temperature kilns to aerospace satellites, a material known as the “industrial diamond” is quietly rewriting the boundaries of modern manufacturing. Silicon carbide ceramics, a superhard material with a hardness second only to natural diamond, is causing a silent revolution in various fields such as modern industry, semiconductors, aerospace, and new energy due to its high temperature resistance, strong radiation resistance, and excellent thermal conductivity.

When ‘hard bones’ encounter precision manufacturing

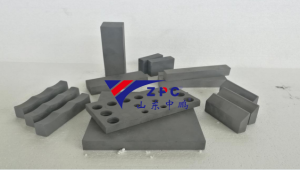

If traditional ceramics are blue and white porcelain in arts and crafts, then silicon carbide ceramics are more like Swiss watches in precision instruments. Its hardness is 3-5 times that of ordinary ceramics, and this hardness close to natural diamonds makes the machining process like carving on steel plates – ordinary cutting tools wear out at an astonishing speed during cutting. What’s even more tricky is that the “tough” nature of silicon carbide makes it prone to edge cracking with even a slight mistake during processing, especially for some thin-walled parts that require the same caution as crystal artworks.

But the demand of modern industry is driving technological breakthroughs. Engineers have found that the key to solving this problem lies in the combination of rigidity and flexibility: maintaining the intrinsic properties of the material while applying precise control during the processing. Just like top chefs mastering the heat, modern processing techniques gradually tame this stubborn material through precise control of temperature, pressure, and vibration frequency.

Three keys to unlock industrial diamonds

1. Hot pressing molding

This is one of the most common methods for processing silicon carbide ceramics. This method places silicon carbide powder or mixed powder in a hot pressing mold and processes it into shape under high temperature and pressure. It has high production efficiency and forming accuracy, and is suitable for producing large-scale silicon carbide ceramic products such as cutting tools, hot drawn aluminum plates, etc.

2. Grouting molding

This is a low-cost and fast forming method for silicon carbide ceramic products. This method mixes silicon carbide powder with other additives, adds them to water to make a slurry, and injects it into a molding mold. Then, it is processed and formed through drying and high-temperature sintering, with a short processing cycle and low cost. It is suitable for preparing high-strength, high-density parts and load-bearing components.

3. Powder metallurgy

Powder metallurgy is a method of mixing and shaping silicon carbide powder in a certain proportion, and then sintering it at high temperature and high pressure. This method has a simple production process, diverse product shapes, and high processing accuracy, making it suitable for producing high-precision, high-strength, and wear-resistant ceramic products.

From laboratory samples to mass production on the production line, the breakthrough in the processing of silicon carbide ceramics confirms a truth: there is no material that cannot be processed, only technology that has not yet been broken through. With the maturity of new technologies such as laser processing and microwave sintering, this once daunting superhard material is rejuvenating in smart factories, injecting hard core power into “Chinese intelligent manufacturing”.

In the vast ocean of space exploration and the green wave of clean energy, silicon carbide ceramics are writing an industrial legend of this era with their unique material charm. This showdown between hardness and intelligence may be an eternal epitome of humanity breaking through technological boundaries.

Post time: Apr-09-2025