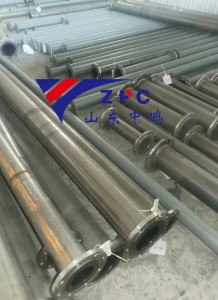

In the industrial scene where high temperature, corrosion, and wear coexist, the dilemma of frequent replacement of traditional metal pipelines is being broken by a new material pipeline – silicon carbide wear-resistant pipelines, with their unique material properties, have sparked a technological revolution in the transmission system in the industrial field.

1、 Outstanding performance beyond the limits of traditional materials

Silicon carbide wear-resistant pipes have demonstrated amazing performance parameters in laboratory validation: a Vickers hardness of 2800HV can withstand continuous erosion from diamond sand, and in coal powder transportation scenarios in thermal power plants, their service life is nearly 15 times longer than traditional alloy pipes.

In extreme temperature environment testing, silicon carbide pipes maintain structural integrity at a high temperature of 1350 ℃, with a thermal expansion coefficient only one-third that of stainless steel. According to application cases, in the continuous transportation of high-temperature metal particles, the pipeline has been running continuously for 8000 hours without deformation or cracking.

In response to the strong corrosion challenge in the chemical industry, silicon carbide materials perform excellently in concentrated sulfuric acid. Data shows that under the same operating conditions, the service life of silicon carbide pipes is 8.2 times that of titanium alloy pipes.

2、 Technological breakthroughs in cross industry applications

In the production line of positive electrode materials for lithium batteries, silicon carbide straight pipes solve the transportation problem in the high-temperature calcination process. Its lightweight characteristics greatly improve installation efficiency, coupled with special conductive design, successfully eliminating static electricity hazards in the production process.

The application in the mining field is more breakthrough: After a copper ore beneficiation plant adopted silicon carbide composite pipelines, the maintenance cycle of the slurry conveying system was significantly extended, which greatly saved maintenance costs.

3、 Continuous evolution of precision manufacturing processes

The 2-meter integral formed pipeline manufactured using reaction sintering technology breaks through the size limitations of traditional ceramic parts. Through gradient sintering process control, the precision machining level of pipeline wall thickness error is minimized.

Currently, we are based on school enterprise cooperation and collaborating with top universities to develop high-quality silicon carbide ceramic products that better meet the diverse needs of users, including silicon carbide wear-resistant pipes.

In the new industrial era, silicon carbide wear-resistant pipes are no longer just a material replacement solution, but a key component driving the intelligent upgrading of process industries. The material revolution, from the material transportation of smart factories to the core components of new energy equipment, is redefining the reliability standards of industrial transmission. We continue to cultivate material innovation and are committed to providing customized solutions for various industries, helping customers build more efficient and sustainable production systems.

If you are also interested in our products, please visit [Shandong Zhongpeng] for more product details, or call (+86)15254687377 to make an appointment for energy efficiency diagnosis on the production line – let’s work together, achieve win-win cooperation, and embark on a new chapter in the industrial field.

Post time: Apr-01-2025